Fast charging of energy-dense lithium-ion batteries

Oct 12, 2022 · True fast charging batteries would have immediate impact; a conventional long-range EV with a 120 kWh pack requiring an hour to recharge could be replaced with an EV

Fast charge algorithm for large Lithium Ion battery packs

Mar 21, 2024 · DRS has developed and tested an improved Lithium Ion Battery Pack recharge algorithm that supports safely recharging in twice (2x) the discharge time. Energy Storage is a

Optimal Charging Voltage for Lithium Batteries

Jul 22, 2023 · Discover the optimal charging voltages for lithium batteries: Bulk/absorb = 14.2V–14.6V, Float = 13.6V or lower. Avoid equalization (or set

Study on Li-ion battery fast charging strategies: Review,

Nov 15, 2022 · At the atomic scale level, the key factors that affect the Lithium-ion battery''s fast charging are electric potential diffusion and charge transfer [4]. At the nanoscale and

Battery Pack Calculator | Good Calculators

Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and maximum discharge

Lithium-ion battery fast charging: A review

Aug 1, 2019 · In the recent years, lithium-ion batteries have become the battery technology of choice for portable devices, electric vehicles and grid storage. Whil

How to Properly Charge Lithium Batteries

Apr 11, 2025 · How Does Temperature Affect Lithium Battery Charging? Charging below 0°C causes lithium plating, reducing capacity. Above 45°C accelerates electrolyte decomposition.

Design and Implementation LiFePO4 Battery Pack of

DC fast charging system is designed to charge 1C, 2C, and 3C with a maximum current of 30 A to a LiFePO4 battery pack with a nominal voltage of 48 V. DC fast charging system uses a

Optimal fast charging strategy for series-parallel configured lithium

Jan 1, 2025 · The limited charging performance of lithium-ion battery (LIB) packs has hindered the widespread adoption of electric vehicles (EVs), due to the complex arrangement of numerous

How to Properly Charge Lithium-ion Batteries for Maximum

Jul 17, 2025 · Charging lithium-ion batteries with the right voltage, current, and temperature control extends battery life and ensures safe, reliable performance.

How to Charge a Lithium-Ion Battery Properly: Step-by-Step

Nov 15, 2024 · Learn how to charge a lithium-ion battery safely and effectively with our guide to best practices, tips, and charging do''s and don''ts.

Recent advances in fast-charging lithium-ion batteries:

Jan 15, 2025 · With the expansion of electric vehicles (EVs) industry, developing fast-charging lithium (Li)-ion batteries (LIBs) is highly required to eliminate the

Battery Charging

Apr 1, 2023 · This drop in battery voltage is used to terminate fast charge in a -DV Detector, which continuously monitors the battery voltage and shuts off the charger when the voltage drops by

Optimal fast charging strategy for series-parallel configured lithium

Jan 1, 2025 · Leveraging the derived battery pack model, we introduce a refined online fast charging framework that mitigates lithium deposition. Fig. 3 outlines the architecture and

BU-808: How to Prolong Lithium-based Batteries

Oct 11, 2023 · The Li-ion charger turns off the charge current and the battery voltage reverts to a more natural level. This is like relaxing the muscles after a

The next generation of fast charging methods for Lithium-ion batteries

Jul 1, 2022 · Consequently, fast charging accelerates battery degradation and reduces battery life. In order to facilitate the design of optimal fast charging strategies, this paper analyzes the

Charging control strategies for lithium‐ion

Nov 26, 2021 · The expanding use of lithium-ion batteries in electric vehicles and other industries has accelerated the need for new efficient charging strategies

Fast Charging Techniques for LFP Batteries in EVs

Jul 4, 2025 · Fast charging lithium iron phosphate (LFP) batteries presents significant electrochemical challenges. During rapid charging events, current densities can exceed 3C

Lithium-ion battery fast charging: A review

Jan 23, 2025 · The present paper reviews the literature on the physical phenomena that limit battery charging speeds, the degradation mechanisms that commonly result from charging at

Optimization of charging strategy for lithium-ion battery packs

May 1, 2021 · This study focuses on a charging strategy for battery packs, as battery pack charge control is crucial for battery management system. First, a single-

6 FAQs about [Lithium battery pack fast charging voltage]

Why do lithium-ion batteries deteriorate during fast charging?

During fast charging of lithium-ion batteries (LIBs), cell overheating and overvoltage increase safety risks and lead to faster battery deterioration. Moreover,

Why is charge time important in fast charging a battery pack?

Charge time is a key metric for a battery pack, especially packs in transport applications. As technology evolves there is a push to reduce charge times. The above graph shows the time to charge from a usable 10 to 80% state of charge. When looking at the key parameters in fast charging a battery pack it is worth looking at the complete system.

How should a lithium battery pack be charged?

It is recommended that lithium battery packs be charged at well-ventilated room temperature or according to the manufacturer’s recommendations. Avoid exposing the battery to extreme temperatures when charging, as this can affect its performance and life.

Should you use a certified charger to charge lithium battery packs?

Using a certified charger to charge lithium battery packs must be considered. Regulatory agencies have tested and approved certified chargers to meet safety standards and specifications, reducing the risk of potential hazards such as short circuits or overheating during the charging process.

Which charger should I use for my Li-ion battery pack?

The correct specification charger is critical for optimal performance and safety when charging Li-Ion battery packs. Your charger should match the voltage output and current rating of your specific battery type.

Can a fast charging method reduce lithium plating risks?

Yang et al. introduced a fast charging method for a 6P1S (six-parallel) battery model based on a thermal and aging coupled single particle model (SPM) to mitigate lithium plating risks. Their study further explored the impact of branch and interconnect resistances on module performance.

Learn More

- Lithium battery pack 1000V high voltage charging and discharging

- European Union lithium battery pack series charging

- How fast is considered fast charging for lithium battery packs

- Lithium battery pack voltage container

- Lithium battery pack charging and discharging balancing machine

- Lithium battery pack medium and high voltage box

- Minimum allowable voltage of lithium iron phosphate battery pack

- 60v lithium iron phosphate battery pack charging current

- Lithium battery pack voltage type

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

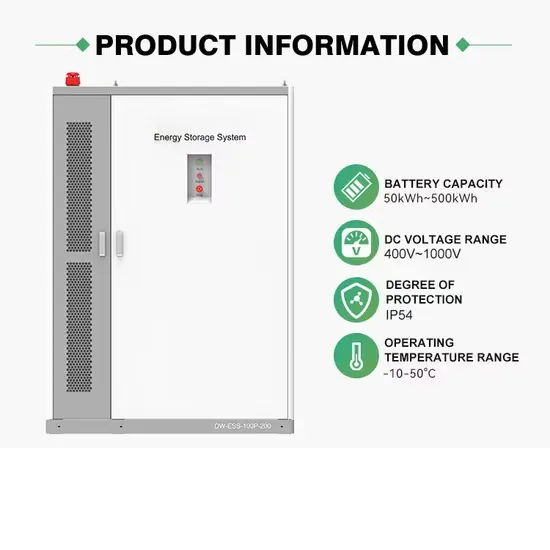

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.