What Is A 60V Lithium Battery Voltage Chart?

Jul 11, 2025 · A 60V lithium battery voltage chart outlines state-of-charge (SoC) against voltage levels for lithium-ion (Li-ion) or lithium iron phosphate (LiFePO4) systems. At full charge, a 60V

How To Charge Lithium Iron Phosphate (LiFePO4) Batteries

Jan 10, 2025 · Charging Current: A safe charging rate is usually 0.2C to 0.5C. For example, for a 100Ah battery, a charging current of 20A to 50A is usually safe.

Lithium iron phosphate battery pack 60v120a

Original Lithium Iron Phosphate LiFePO4 Battery 60V Original Lithium Iron Phosphate LiFePO4 Battery 60V 30Ah Cell Deep Cycles for Electric Bike EBike Electric Cycle 5 Year Life in

Lithium LiFePO4 Batteries for Trolling Motors

Apr 26, 2025 · Lithium-iron-phosphate (LiFePO₄) batteries weigh roughly 60% less than equivalent lead-acid units, deliver high-current output, and last far

LiFePO4 Battery User Manual

Dec 24, 2020 · 1. Applicable Range This product specification applies to lithium iron phosphate battery products provided by our company. The product we provide (and which is described in

What Are the Best Practices for Charging a 60V LiFePO4 Battery?

Sep 6, 2024 · Best practices for charging a 60V LiFePO4 battery include using an appropriate charger with correct voltage settings (67.2V cut-off), avoiding overcharging or deep

Original Lithium Iron Phosphate LiFePO4 Battery

6 days ago · We use Brand New Lithium Iron Phosphate Cell For Electric BIKES Voltage – 3.2VAmpere – 25Ah Condition – Brand New Lithium offers several

How to Charge a Lithium Iron Phosphate Battery

May 6, 2025 · A complete guide to charging lithium iron phosphate batteries: learn the optimal voltage and current, precautions for cold and hot conditions, and how to ensure long-term

High Capacity 60V 30Ah Lithium Iron Phosphate Battery Pack

Explore unbeatable offers on High-Capacity 60V 30Ah Lithium Iron Phosphate Battery Pack with Built-in BMS and Charger. Shop now and enjoy amazing discounts on bulk purchases.

The principle of charging lithium iron phosphate battery pack

May 24, 2022 · The charging method of lithium iron phosphate battery pack is constant current and constant voltage charging, and the charging method of lead-acid battery is pulse, so

LiFePO4 BMS Selection Guide: Matching Your Pack''s Voltage,

Aug 19, 2025 · LiFePO4 BMS Selection Guide: Matching Your Pack''s Voltage, C-Rating, and Current Lithium iron phosphate (LiFePO4) batteries have become one of the most reliable and

How to Properly Charge LiFePO4 Battery with a

Jan 8, 2025 · Lithium Iron Phosphate (LiFePO4) batteries are known for their long lifespan, reliability, and safety. People widely use them in solar systems, RVs,

lifepo4 battery pack 60V 36Ah For EV

Sep 30, 2021 · Purchase a LiFePO4 battery pack 60V 36Ah for your electric vehicle (EV). This high-capacity battery is engineered for improved performance and long-lasting power,

The Ultimate Guide to 60v 100ah Lithium Batteries and Beyond

Oct 10, 2024 · Why Choose a 60v 100ah Lithium Battery? Choosing the right battery can be a daunting task with so many options out there. However, the 60v 100ah lithium battery brings

6 FAQs about [60v lithium iron phosphate battery pack charging current]

What is lithium iron phosphate (LiFePO4) battery?

Lithium Iron Phosphate (LiFePO4) batteries are known for their long lifespan, reliability, and safety. People widely use them in solar systems, RVs, boats, and electric vehicles. However, charging these batteries properly with a power supply is crucial to maintain their performance and longevity.

What is the charging voltage for a LiFePO4 battery pack?

Each LiFePO4 cell has a nominal voltage of 3.2V and a maximum charging voltage of 3.65V. To calculate the correct charging voltage for a battery pack, multiply 3.65V by the number of cells in series: Important tips: Always set the power supply to the exact voltage required for your battery pack.

How do you charge a battery pack with a power supply?

Set the voltage: Adjust the power supply to the correct voltage for your battery pack. Set the current limit: Configure the power supply to the appropriate charging current (0.2C to 0.5C). Monitor the charging process: Use a multimeter to confirm the voltage and current.

Can LiFePO4 batteries be overcharged?

The charging voltage and current need to be carefully monitored to provide for safe and fast charging of the LiFePO4 batteries. If the applied voltage or current level is too high, it may cause overcharging which will lead to the generation of excess heat and escalate the chances of cell damage.

How does a LiFePO4 battery work?

Working Principle of a LiFePO4 Battery Charging Process: During charging, lithium ions move from the LiFePO4 cathode to the graphite anode through the electrolyte and separator. Electrons travel through the external circuit to balance the charge, resulting in the conversion of LiFePO4 into iron phosphate.

Are lithium iron phosphate batteries better than SLA batteries?

If you’ve recently purchased or are researching lithium iron phosphate batteries (referred to lithium or LiFePO4 in this blog), you know they provide more cycles, an even distribution of power delivery, and weigh less than a comparable sealed lead acid (SLA) battery. Did you know they can also charge four times faster than SLA?

Learn More

- New 60v lithium iron phosphate battery pack

- What is the actual life of a 60v lithium iron phosphate battery pack

- Price of No 9 lithium iron phosphate battery pack

- Minimum allowable voltage of lithium iron phosphate battery pack

- Lithium iron phosphate battery pack in Manchester UK

- Light truck lithium iron phosphate battery pack

- 48v 10a lithium iron phosphate battery pack

- How much does a 80KWh lithium iron phosphate battery pack cost

- Zhongya lithium iron phosphate battery pack customization

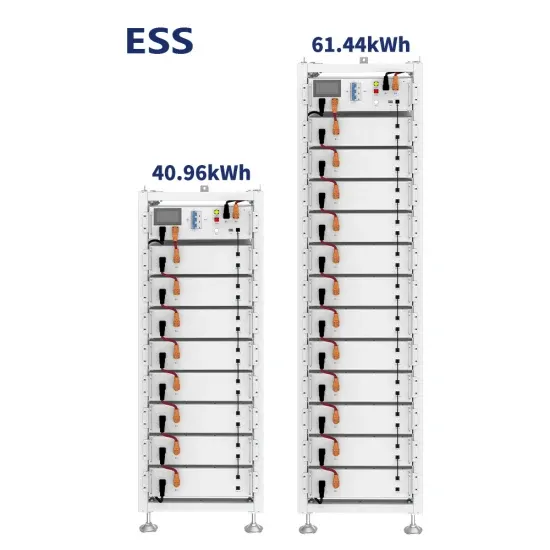

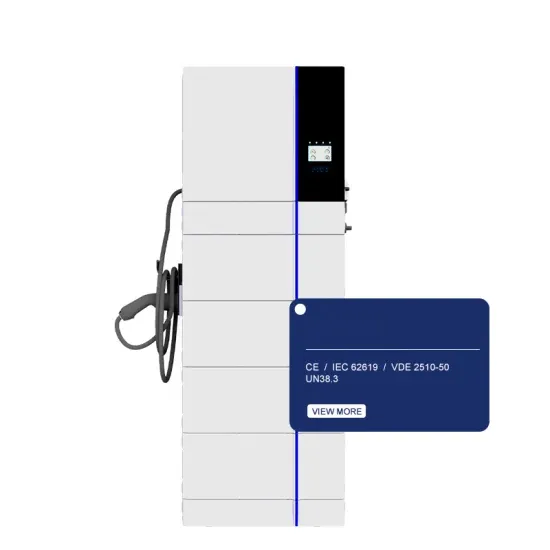

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.