The Relationship between Voltage and Capacity

Sep 2, 2019 · An LFP battery refers to a li-ion battery using lithium iron phosphate as a positive electrode material. Knowing the relevant voltage of the LFP

A Comprehensive Guide to LiFePO4 Voltage Chart – Renogy US

Lithium Iron Phosphate (LiFePO4) batteries have revolutionized energy storage with their exceptional performance, longevity, and safety features. At the heart of understanding and

A Comprehensive Guide to LiFePO4 Voltage Chart – Renogy US

Every lithium iron phosphate battery has a nominal voltage of 3.2V, with a charging voltage of 3.65V. The discharge cut-down voltage of LiFePO4 cells is 2.0V. Here is a 3.2V battery

Optimal Charging Voltage for Lithium Batteries

Jul 22, 2023 · LiFePO4 Batteries: Lithium Iron Phosphate (LiFePO4) batteries, with a nominal voltage of 3.2 volts per cell, require a specific charging profile

LiFePO4 Battery Voltage Chart: Your Ultimate

May 11, 2024 · LiFePO4, which stands for Lithium Iron Phosphate, is a type of lithium-ion battery chemistry known for its stability, high energy density, and

How Do Lithium Iron Phosphate Battery Packs Work and

Lithium iron phosphate (LiFePO4) battery packs are a type of rechargeable battery known for their safety, longevity, and environmental friendliness. They operate by transferring lithium ions

The Comprehensive Guide to LiFePO4 Lithium

Jul 10, 2024 · In this detailed guide, we''ll explore the nuances of LiFePO4 lithium battery voltage, offering clear insights on how to interpret and effectively use a

Official Depth Of Discharge Recommendations For LiFePO4

Oct 12, 2024 · Conversely LIFEPO4 (lithium iron phosphate) batteries can be continually discharged to 100% DOD and there is no long term effect. You can expect to get 3000 cycles

What is the Lowest Voltage for a Lithium Iron Phosphate Battery?

Oct 25, 2024 · The lowest voltage for a lithium iron phosphate (LiFePO4) battery is typically around 2.5V per cell. Therefore, for a standard LiFePO4 battery pack with multiple cells in

Lithium Ion Battery Specifications

Oct 28, 2015 · Design of positioning the battery pack in application and charger To prevent the deterioration of the battery performance caused by heat, battery shall be positioned away from

Optimal Lithium Battery Charging: A Definitive

Mar 12, 2024 · Unlock the secrets of charging lithium battery packs correctly for optimal performance and longevity. Expert tips and techniques revealed in our

Lithium Iron Phosphate Battery

The lithium iron phosphate battery (LiFePO4 battery) or LFP battery (lithium ferrophosphate) is a type of lithium-ion battery using lithium iron phosphate (LiFePO4) as the cathode material, and

Lithium Battery Voltage Chart: 3.2V, 3.7V, 4.2V

Jan 4, 2024 · What is a Battery Voltage Chart? A battery voltage chart is a critical tool for understanding how different lithium-ion batteries perform under specific

6 FAQs about [Minimum allowable voltage of lithium iron phosphate battery pack]

What is a 3.2V lithium iron phosphate battery?

3.2V lithium iron phosphate battery refers to the nominal voltage of the battery cell. That is, the average voltage from the beginning to the end of discharge (the voltage we often say is dead) after the battery cell is fully charged.、 B. 3.65 V LiFePO4 battery

What voltage does a lithium iron phosphate (LiFePO4) battery have?

We understand the importance of having accurate and reliable information about lithium iron phosphate (LiFePO4) batteries and their voltage characteristics. In this comprehensive guide, we aim to provide you with detailed insights into LiFePO4 battery voltages across various systems, including 3.2V, 12V, 24V, and 48V.

What is the nominal voltage of a lithium iron phosphate battery?

As mentioned, the nominal voltage of a single lithium iron phosphate battery is 3.2 V, the charging voltage is 3.6 V, and the discharge cut-off voltage is 2.0 V. The lithium iron phosphate battery pack reaches the voltage the equipment requires through the series combination of cells. The battery pack voltage = N * the number of series connections.

How much voltage does a LiFePO4 battery need?

The typical bulk charging voltage for LiFePO4 batteries is around 14.2-14.6V per 12V battery, or 3.45-3.65V per cell, depending on the specific battery and manufacturer recommendations. What is the low voltage cutoff for LiFePO4 batteries?

What is the low voltage cutoff for LiFePO4 batteries?

The low voltage cutoff for LiFePO4 batteries is typically around 2.5-3.0V per cell to protect the battery from deep discharge and potential damage. What is the importance of bulk, float, and equalize voltages in charging LiFePO4 batteries?

What is a safe discharge voltage for a LiFePO4 cell?

Discharge Voltage Limits: The safe discharge range for a 3.2V LiFePO4 cell is from 2.50V to 3.20V. Discharging below 2.50V can lead to irreversible damage and decreased battery capacity. It is advisable to integrate a Battery Management System (BMS) to prevent discharging below this critical threshold.

Learn More

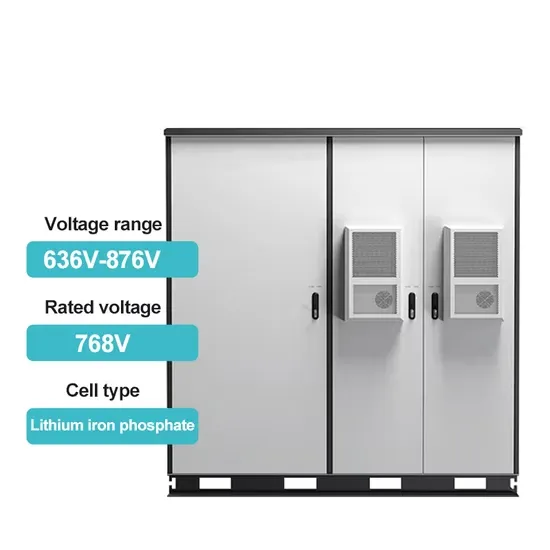

- Imported lithium iron phosphate battery pack

- Zhongya lithium iron phosphate battery pack customization

- 60v lithium iron phosphate battery pack charging current

- Lithium iron phosphate battery pack in Manchester UK

- New 60v lithium iron phosphate battery pack

- Lithium battery pack and lithium iron phosphate prices in Mozambique

- Price of No 9 lithium iron phosphate battery pack

- Lithium iron phosphate power battery pack

- Lithium iron phosphate battery service life of energy storage cabinet

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.