What Are LiFePO4 Lithium Iron Phosphate Battery Packs and

Feb 26, 2025 · LiFePO4 (lithium iron phosphate) battery packs are rechargeable energy storage systems using lithium-ion chemistry with a phosphate-based cathode. They offer high thermal

Lithium Iron Phosphate Battery Packs: Powering the Future

Apr 22, 2025 · In the dynamic landscape of energy storage technologies, lithium - iron - phosphate (LiFePO₄) battery packs have emerged as a game - changing solution. These

Lithium Iron Phosphate Battery Packs | Electronic

A battery pack is a set of any number of battery cells connected and bound together to form a single unit with a specific configuration and dimensions. They may be configured in series,

Li-ion battery vs. lithium iron phosphate: a full-dimensional

Mar 11, 2025 · *Lithium iron phosphate batteries: the main components are iron (Fe), phosphorus (P), lithium (Li), raw material cost is 30%-40% lower (iron ore price is only $120/ton).

Lithium Iron Phosphate Battery

The lithium iron phosphate battery (LiFePO4 battery) or LFP battery (lithium ferrophosphate) is a type of lithium-ion battery using lithium iron phosphate (LiFePO4) as the cathode material, and

Explore LFP Battery Raw Material: LFP Cathode

Jan 30, 2024 · Lithium iron phosphate is an important cathode material for lithium-ion batteries. Due to its high theoretical specific capacity, low manufacturing

What Are the Pros and Cons of Lithium Iron Phosphate Batteries?

Jan 5, 2024 · Lithium iron phosphate (LiFePO4) batteries offer several advantages, including long cycle life, thermal stability, and environmental safety. However, they also have drawbacks

Lithium Iron Phosphate (LFP)

Oct 5, 2023 · Lithium Iron Phosphate (LFP) Lithium ion batteries (LIB) have a dominant position in both clean energy vehicles (EV) and energy storage systems (ESS), with significant

Lithium Iron Phosphate Battery Packs: Powering the Future

Apr 22, 2025 · 1. Introduction In the dynamic landscape of energy storage technologies, lithium - iron - phosphate (LiFePO₄) battery packs have emerged as a game - changing solution.

Techno-economic analysis of lithium-ion battery price

Nov 1, 2023 · Secondly, techno-economic analysis predicts that the mean price of EV battery packs with diverse chemical compositions will decline to $75.1/kWh by 2030, factoring in the

Li-ion battery vs. lithium iron phosphate: a full-dimensional

Mar 11, 2025 · With the explosive growth of the robotics industry in the industrial, service and medical fields, the battery, as its core power source, accounts for up to 20%-40% of the cost.

Status and prospects of lithium iron phosphate

Sep 23, 2024 · Lithium iron phosphate (LiFePO4, LFP) has long been a key player in the lithium battery industry for its exceptional stability, safety, and cost-effectiveness as a cathode

Optimum Selection of Lithium Iron Phosphate Battery Cells

Mar 20, 2025 · This paper presents a systematic approach to selecting lithium iron phosphate (LFP) battery cells for electric vehicle (EV) applications, considering cost, volume, aging

Navigating the pros and Cons of Lithium Iron

Mar 7, 2024 · Discover the advantages and challenges of Lithium Iron Phosphate batteries in our in-depth analysis. Explore the future potential of this energy

Lithium-Ion Battery Pack Prices See Largest Drop Since 2017,

Dec 11, 2024 · Battery prices saw their biggest annual drop since 2017. Lithium-ion battery pack prices dropped 20% from 2023 to a record low of $115 per kilowatt-hour, according to analysis

Best Lithium Iron Phosphate 12V Battery Pack | LiFePO4

Mar 19, 2025 · A Lithium Iron Phosphate 12V battery pack is a top-tier energy storage solution that delivers long-lasting performance, safety, and efficiency. Whether for renewable energy,

Lithium Iron Phosphate Battery Market Size & Growth [2032]

Aug 4, 2025 · The global lithium iron phosphate battery was valued at $15.28 billion in 2023 & is projected to grow from $19.07 billion in 2024 to $124.42 billion by 2032

What are The Differences Between Fixed Capacity and

Mar 27, 2025 · In the lithium battery production process, "capacity determination" and "capacity division" are two crucial links, especially playing a decisive role in the performance and

An overview on the life cycle of lithium iron phosphate:

Apr 1, 2024 · Lithium Iron Phosphate (LiFePO4, LFP), as an outstanding energy storage material, plays a crucial role in human society. Its excellent safety, low cos

Lithium Iron Phosphate batteries – Pros and

Mar 25, 2021 · Introduction: Offgrid Tech has been selling Lithium batteries since 2016. LFP (Lithium Ferrophosphate or Lithium Iron Phosphate) is currently our

The Role of Lithium Iron Phosphate (LiFePO4) in

Apr 18, 2025 · Lithium iron phosphate is revolutionizing the lithium-ion battery industry with its outstanding performance, cost efficiency, and environmental

Lithium Iron Phosphate vs Lithium-ion Batteries

Lithium iron phosphate or LFB battery is the latest addition. The prices of LFP batteries have also made them handy. Besides that, their efficiencies have also improved. In some parts of the

How Do Lithium Iron Phosphate Battery Packs Work and

A lithium iron phosphate battery pack consists of multiple cells using lithium iron phosphate (LiFePO4) as the cathode material. This configuration provides a stable and safe environment

Understanding Lithium Iron Phosphate Batteries:

Feb 21, 2025 · In recent years, lithium iron phosphate (LiFePO4) batteries have gained significant attention as a viable energy storage solution across various

6 FAQs about [Lithium battery pack and lithium iron phosphate prices in Mozambique]

What is lithium iron phosphate?

Lithium iron phosphate is revolutionizing the lithium-ion battery industry with its outstanding performance, cost efficiency, and environmental benefits. By optimizing raw material production processes and improving material properties, manufacturers can further enhance the quality and affordability of LiFePO4 batteries.

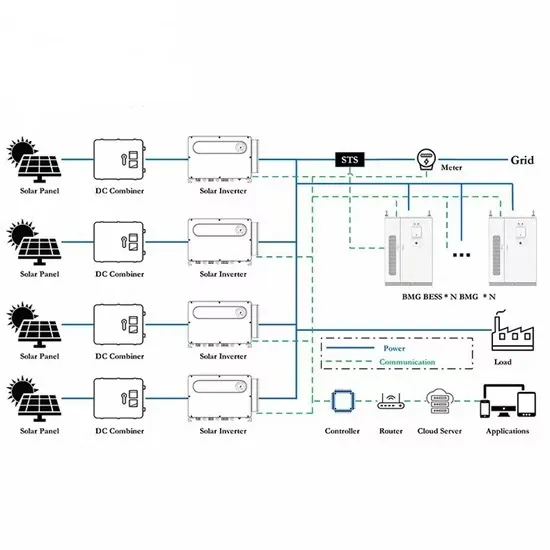

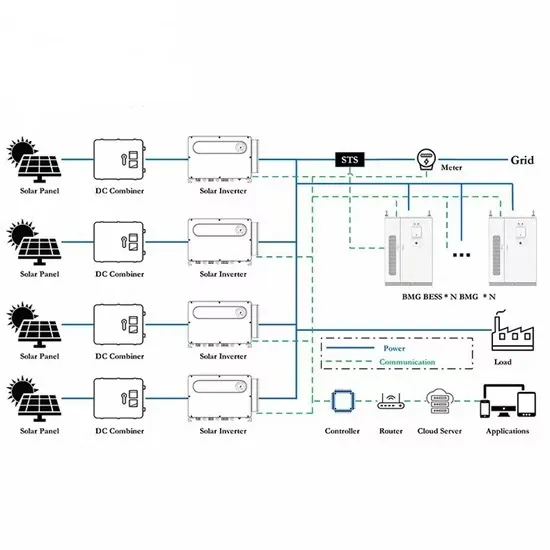

What is a lithium iron phosphate battery energy storage system?

The lithium iron phosphate battery energy storage system consists of a lithium iron phosphate battery pack, a battery management system (Battery Management System, BMS), a converter device (rectifier, inverter), a central monitoring system, and a transformer.

What is lithium iron phosphate (LiFePO4)?

Lithium iron phosphate (LiFePO4) has emerged as a game-changing cathode material for lithium-ion batteries. With its exceptional theoretical capacity, affordability, outstanding cycle performance, and eco-friendliness, LiFePO4 continues to dominate research and development efforts in the realm of power battery materials.

Why is the demand for lithium iron phosphate batteries increasing?

The increasing sales of electronics vehicles and energy storage devices will contribute to the demand for LFP batteries. The increasing focus of the government bodies towards greenhouse gas emissions in the European region has supported the lithium iron phosphate battery market growth.

What is a LiFePO4 battery pack?

Suitable for a variety of applications, LiFePO4 battery packs offer excellent safety and impressive cycle life, while being lightweight, easy to use and affordable. Lithium iron phosphate battery pack is an advanced energy storage technology composed of cells, each cell is wrapped into a unit by multiple lithium-ion batteries.

What are the advantages of lithium iron phosphate battery?

Lithium iron phosphate battery has a series of unique advantages such as high working voltage, high energy density, long cycle life, green environmental protection, etc., and supports stepless expansion, and can store large-scale electric energy after forming an energy storage system.

Learn More

- How much does a 80KWh lithium iron phosphate battery pack cost

- Minimum allowable voltage of lithium iron phosphate battery pack

- What is the price of lithium iron phosphate battery pack

- New 60v lithium iron phosphate battery pack

- What is the actual life of a 60v lithium iron phosphate battery pack

- 36v12ah lithium iron phosphate battery pack

- Zhongya lithium iron phosphate battery pack customization

- 60kwh lithium iron phosphate battery pack price

- Export lithium iron phosphate battery pack factory

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.