Home Energy Storage Solar Battery | Shenzhen XIHO Lithium Battery

Discover EVE Energy''s next-generation all-solid-state batteries, delivering 350Wh/kg by 2026 and over 1000Wh/L by 2028. Featuring high-nickel cathodes, silicon-carbon anodes, and dual

Top 10 Lithium Battery Manufacturers in China 2025

Jan 26, 2024 · 2025 China top 10 lithium battery manufacturers comparison. Production capacity, UN/IEC certifications, OEM services for EV and energy storage solutions.

American Battery Factory Breaks Ground On Largest U.S. Lithium Iron

TUCSON, AZ (October 26, 2023) — American Battery Factory (ABF), an emerging battery manufacturer leading the development of the first network of lithium iron phosphate (LFP)

Vietnam aims for more in global battery supply

Jan 10, 2023 · The factory is designed to annually produce 30 million lithium iron phosphate (LFP) battery cells, which will be used for EVs and energy storage

Quality LiFePO4 Prismatic Cell & LiFePO4 Battery Pack factory

12v 24v 100ah 120ah 200ah 300ah Lifepo4 Bluetooth Iron Phosphate Battery Batterie 100 Kwh Lithium Pack With Bluetooth Quality LiFePO4 Prismatic Cell & LiFePO4 Battery Pack factory

China restricts battery cathode material

Jul 15, 2025 · Beijing has added battery cathode material preparation technology to its restricted export list. The move affects lithium iron phosphate (LFP) and

Custom LiFePO4/LiFeMnPO4 Batteries

FAQ Q: I am trying to charge my battery through Solar Panel. If the battery pack already has the PCB/PCM protection, do I still need the solar charger controller ? A: Yes, you do need the

Development Status and Risk Analysis of the Lithium-Ion Battery

Aug 20, 2024 · The lithium-ion battery industry should actively expand its trade partnerships to reduce dependence on specific markets and enhance global market competitiveness and risk

China''s Lithium Battery Industry Go Global III: Venturing

Jul 27, 2023 · Since 2021, Chinese lithium battery manufacturers, led by CATL (宁德时代), have accelerated overseas factory construction to seize the expanding global market for new

China Issues New Rules on Exports of EV Batteries and

Aug 6, 2025 · The restrictions China implemented include three core technologies linked to battery-cathode production for lithium iron phosphate (LFP) batteries, a popular type of lithium

Charging Up: India''s Potential Role in Global

May 1, 2024 · Specifically, India has the greatest production potential in certain raw materials, precursor materials, lithium-iron-phosphate (LFP) battery cells,

Top 20 Lithium-ion Battery Manufacturers in Vietnam

TMI Lithium Batteries is a prominent manufacturer of lithium-iron phosphate batteries for EVs, energy storage systems, and electric tools. The company''s advanced production process,

How Do Lithium Iron Phosphate Battery Packs Work and

Lithium iron phosphate (LiFePO4) battery packs are a type of rechargeable battery known for their safety, longevity, and environmental friendliness. They operate by transferring lithium ions

Logistics Services for China''s Battery Exports

As the world''s largest battery producer and exporter, China''s battery export data in 2024 is remarkable: wind turbine exports increased by 71.9%; photovoltaic products exported more

China puts new restrictions on EV battery technology in

Jul 18, 2025 · One part of the newly announced restrictions surrounds the battery cathode production technology for the making of lithium iron phosphate (LFP) batteries, a type of

China''s battery makers build plants abroad to

2 days ago · It will be the largest battery factory in Europe when production begins in 2025. According to data from the Ministry of Industry and Information

6 FAQs about [Export lithium iron phosphate battery pack factory]

Will China restrict the export of lithium iron phosphate (LFP)?

China’s Ministry of Commerce has proposed restricting the export of technologies for producing lithium iron phosphate (LFP), an inexpensive cathode material for electric vehicle batteries. Nearly all LFP is made in China, and if the restrictions are implemented, companies outside of China could struggle to catch up.

What is the new lithium iron phosphate export restriction?

The move affects lithium iron phosphate (LFP) and related technologies, requiring export licences to balance development and security. The new restriction covers preparation technologies for battery cathode materials, including lithium iron phosphate, lithium manganese iron phosphate, and phosphate cathode raw materials.

Where are lithium iron phosphate (LFP) cathode powders made?

Nearly all lithium iron phosphate (LFP) cathode powders are produced in China. Taiwan's Aleees is one non-Chinese firm with LFP manufacturing technology. China’s Ministry of Commerce has proposed restricting the export of technologies for producing lithium iron phosphate (LFP), an inexpensive cathode material for electric vehicle batteries.

Why are Chinese lithium iron phosphate battery manufacturers establishing production facilities abroad?

Driven by a continuous surge in overseas orders, Chinese lithium iron phosphate (LFP) battery manufacturers are significantly ramping up their efforts to establish production facilities abroad.

Why has Beijing added battery cathode material preparation technology to its restricted export list?

Beijing has added battery cathode material preparation technology to its restricted export list. The move affects lithium iron phosphate (LFP) and related technologies, requiring export licences to balance development and security.

Can battery cathode material preparation technology be exported?

Manufacturers or exporters of battery-related technologies are required to seek export licences before proceeding with international transfers. “Battery cathode material preparation technology is increasingly being used in sensitive fields,” a Ministry of Commerce spokesperson said.

Learn More

- Price of No 9 lithium iron phosphate battery pack

- 60v lithium iron phosphate battery pack charging current

- What is the actual life of a 60v lithium iron phosphate battery pack

- Rwanda lithium iron phosphate battery pack

- Minimum allowable voltage of lithium iron phosphate battery pack

- Lithium iron phosphate battery pack in Manchester UK

- 48v 10a lithium iron phosphate battery pack

- Zhongya lithium iron phosphate battery pack customization

- British small cylindrical lithium iron phosphate battery

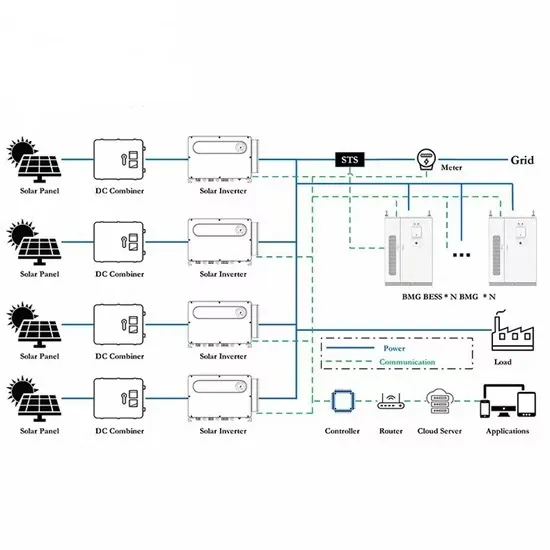

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

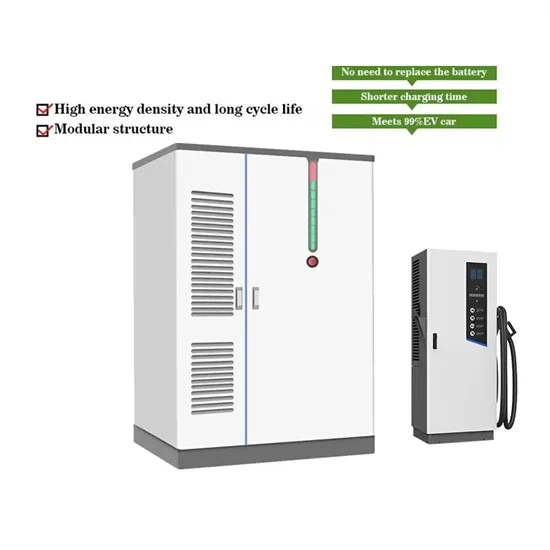

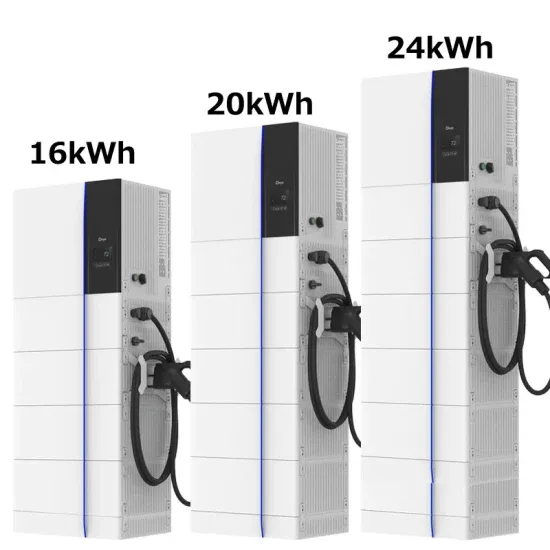

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.