Lithium Iron Phosphate Battery Pack for Energy Storage

Explore the benefits of lithium iron phosphate battery packs, including their use in solar systems, emergency backup, and medical equipment. Learn why these batteries are the future of

Advantages and Disadvantages of LiFePO4 Battery

Jul 24, 2023 · Lithium iron phosphate batteries use for various applications such as electronic machines, military, medical applications, and electric motors. For

What Are LiFePO4 Batteries, and When Should

Sep 7, 2022 · How Are LiFePO4 Batteries Different? Strictly speaking, LiFePO4 batteries are also lithium-ion batteries. There are several different variations in

LFP Battery Pack Combined Heat Dissipation Strategy

Apr 28, 2024 · During the high-power charging and discharging process, the heat generated by the energy storage battery increases significantly, causing the battery temperature to rise

Rwanda Lithium Iron Phosphate Batteries Market (2024-2030

Rwanda Lithium Iron Phosphate Batteries Market (2024-2030) | Growth, Value, Revenue, Outlook, Forecast, Segmentation, Companies, Analysis, Size, Industry, Share & Trends

Custom Battery Packs & Assemblies | Power Solutions

Custom Power designs, develops and manufactures custom lithium primary battery packs and assemblies for a wide range of applications. Utilizing advanced mechanical and electronic

Felicity 17.5kWh LifePO4 Battery with BMS LPBF48350; 350AH 48V Lithium

Buy New Felicity 17.5kWh LifePO4 Battery With BMS LPBF48350; 350AH 48V Lithium Ion Phosphate Battery, Fast Charging, Long Life In Kigali, Rwanda | | 1 Year + Warranty

Lithium Iron Phosphate Battery Packs: Powering the Future

Apr 22, 2025 · The cathode of a LiFePO₄ battery pack is composed of lithium iron phosphate, which has an olivine - type crystal structure. This structure consists of a three - dimensional

Tesla offering LFP retrofits for Model 3 battery replacements

Mar 12, 2024 · Tesla is now offering a lithium-iron-phosphate (LFP) pack retrofit to some Model 3 owners requiring a battery replacement under warranty. This option is now available for those

Luminous 230 Ah 24 V 5.9 kWh Lithium Iron Phosphate

Luminous 230 Ah 24 V 5.9 kWh Lithium Iron Phosphate (LiFePO₄) Solar Battery; Built‑in BMS, Over 6 000 Charge Cycles @ 25 °C (0.5 C, 80 % DoD), Scalable Up to 15 Units

Felicity 100AH 48V 5kWh Lithium Iron Phosphate (LiFePO4) Solar Battery

Felicity 100AH 48V 5kWh Lithium Iron Phosphate (LiFePO4) Solar Battery LPBF48100; Built-in BMS, Over 6,000 Charge Cycles @25°C, 80% DoD, Long Lifespan, Fast Charging

What Are LiFePO4 Lithium Iron Phosphate Battery Packs and

Feb 26, 2025 · LiFePO4 (lithium iron phosphate) battery packs are rechargeable energy storage systems using lithium-ion chemistry with a phosphate-based cathode. They offer high thermal

Africa''s Competitiveness in Global Battery Supply Chains

Nov 1, 2024 · Demand Global battery demand is projected to reach 7.8 TWh by 2035, with China, the US, and Europe representing 80%; Lithium-ion is ~80% of the demand. In Africa, majority

Lithium Iron Phosphate Battery Packs: Powering the Future

Apr 22, 2025 · In the dynamic landscape of energy storage technologies, lithium - iron - phosphate (LiFePO₄) battery packs have emerged as a game - changing solution. These

6 FAQs about [Rwanda lithium iron phosphate battery pack]

What is LiFePO4 battery?

Today, LiFePO4 (Lithium Iron Phosphate) battery pack has emerged as a revolutionary technology. It offers numerous advantages over traditional battery chemistries. As the demand for efficient energy grows, understanding the LiFePO4 battery packs becomes crucial. This comprehensive guide aims to delve into the various aspects of LiFePO4 battery.

Are LiFePO4 batteries toxic?

The materials used in LiFePO₄ battery packs, such as iron, phosphorus, and lithium, are relatively non - toxic compared to some of the heavy metals and toxic chemicals used in other battery chemistries.

How to build a LiFePO4 battery pack?

Building a LiFePO4 battery pack involves several key steps. It is to ensure safety, efficiency, and reliability. Start by gathering LiFePO4 cells, a Battery Management System (BMS). Also, a suitable enclosure, and welding equipment. Arrange the cells in a series or parallel configuration. Consider the desired voltage and capacity before arranging.

What is lithium hexafluorophosphate in a LiFePO4 battery pack?

The electrolyte in a LiFePO₄ battery pack serves as the medium for the transport of lithium ions between the anode and the cathode. It is typically composed of a lithium - containing salt dissolved in an organic solvent. Lithium hexafluorophosphate (LiPF₆) is a commonly used salt in the electrolyte.

What is the future of LiFePO4 battery packs?

In the future, LiFePO₄ battery packs are expected to be more closely integrated with smart grid technologies and energy management systems. This integration will enable better control and optimization of the battery pack's charging and discharging processes based on grid demand, electricity prices, and renewable energy generation forecasts.

Does LiFePO4 cathode have thermal runaway?

The LiFePO₄ cathode material has a lower risk of thermal runaway compared to some other cathode materials. Thermal runaway is a dangerous condition where the battery overheats and can lead to fires or explosions.

Learn More

- 48v 10a lithium iron phosphate battery pack

- 60kwh lithium iron phosphate battery pack price

- Light truck lithium iron phosphate battery pack

- Minimum allowable voltage of lithium iron phosphate battery pack

- How much does a 80KWh lithium iron phosphate battery pack cost

- 60v lithium iron phosphate battery pack charging current

- Lithium iron phosphate battery pack in Manchester UK

- Lithium iron phosphate power battery pack

- New 60v lithium iron phosphate battery pack

Industrial & Commercial Energy Storage Market Growth

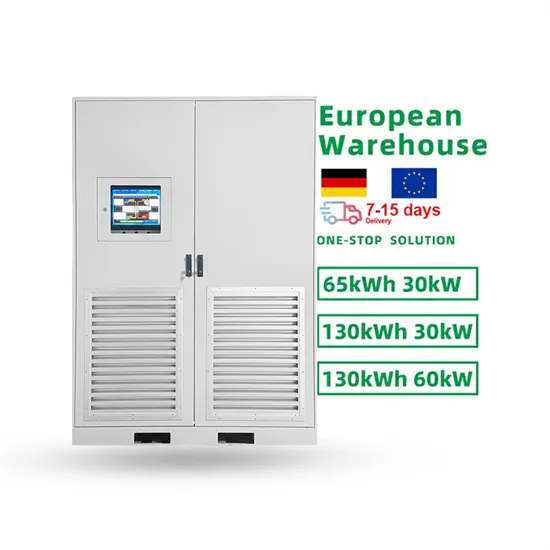

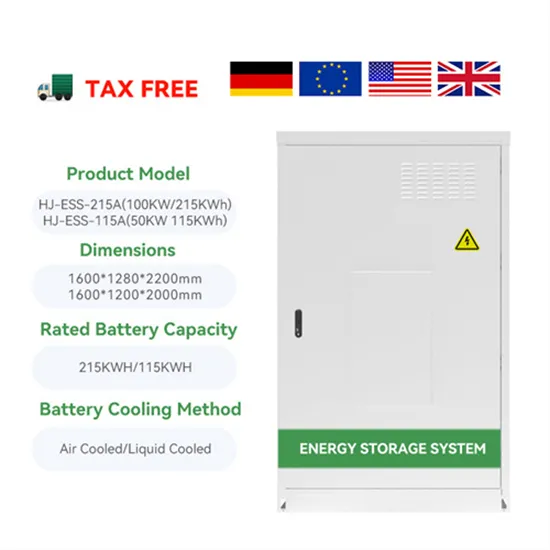

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.