Thermally modulated lithium iron phosphate batteries for mass

Jan 18, 2021 · The pursuit of energy density has driven electric vehicle (EV) batteries from using lithium iron phosphate (LFP) cathodes in early days to ternary layered oxides increasingly rich

24V 175AH Lithium Iron Phosphate Battery Pack Anti

Durable Design for Heavy-Duty Use: This 24V 175AH lithium iron phosphate battery pack is designed for heavy-duty applications, with an IP67 rating ensuring protection against dust and

Light Truck Lithium Iron Phosphate Battery Packs Benefits

As the transportation industry shifts toward sustainable energy solutions, lithium iron phosphate (LiFePO4) battery packs are becoming the go-to choice for light truck applications. This article

Lithium Pros: High Performance Ultra

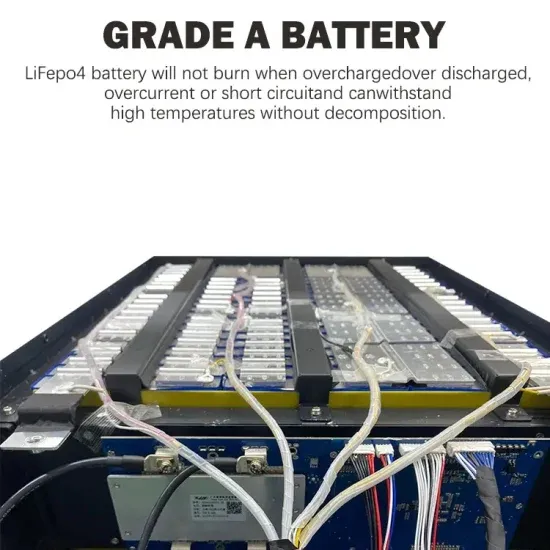

Mar 11, 2019 · Also, their batteries use Lithium Iron Phosphate which is the safest form of lithium chemistry. So, after getting it buttoned up in only a few minutes,

Designing better batteries with LFP

Jan 15, 2025 · One particularly exciting advancement from the company is its innovative design approach to Lithium Iron Phosphate (LFP) battery packs, says CTO Harry Husted. "LFP brings

Why LiFePO4 Batteries Are the Best Choice for Semi Trucks

Apr 18, 2025 · Why Choose LiFePO4 Batteries for Your Semi Truck? Selecting the right battery for your semi truck is essential for reliability, performance, and longevity. Among the many

25.6V304Ah High-Durability Lithium Iron Phosphate Power Cell

Aug 9, 2025 · Core Energy Source for New Energy Commercial Vehicle Powertrains . 153.6V high-voltage platform × 35.27kWh high energy density: A single pack enables a 4-ton electric

truck battery | truck battery power | electric truck

Aug 24, 2024 · It uses lithium iron phosphate long-life batteries, and the battery energy is as high as 232kWh is safe and intelligent. It can be used in

Everything You Need to Know About LiFePO4 Battery Cells: A

Apr 18, 2025 · Complete Guide to LiFePO4 Battery Cells: Advantages, Applications, and Maintenance Introduction to LiFePO4 Batteries: The Energy Storage Revolution Lithium Iron

Lithium Iron Phosphate Battery Packs: Powering the Future

Apr 22, 2025 · In the dynamic landscape of energy storage technologies, lithium - iron - phosphate (LiFePO₄) battery packs have emerged as a game - changing solution. These

What Are LiFePO4 Batteries, and When Should

Sep 7, 2022 · How Are LiFePO4 Batteries Different? Strictly speaking, LiFePO4 batteries are also lithium-ion batteries. There are several different variations in

5 facts about LFP chemistry for electric vehicle

Sep 22, 2022 · Lithium iron phosphate batteries first came to light in 1996, so it''s not surprising this battery chemistry is already present in the electric vehicle

25.6V304Ah High-Durability Lithium Iron Phosphate Power Cell

Aug 9, 2025 · Verified Cases: Shenzhen Express Light Truck Fleet (daily 180km operation): 3 battery packs per vehicle increased cargo capacity by 15%, saving ¥260,000 annually in diesel

24V 175AH Lithium Iron Phosphate Battery Pack Anti

High Performance for Electric Vehicles: With a system power supply of 4.48 kWh and a maximum starting current of 3000A, this battery pack provides reliable power for electric vehicles,

6 FAQs about [Light truck lithium iron phosphate battery pack]

What are lithium iron phosphate battery stocks?

Lithium-based batteries, specifically lithium iron phosphate batteries (LFP batteries), have become popular for renewable energy storage and EV power. Lithium iron phosphate batteries are a favorite in the battery market, and as a result, investors are eager to get exposure to lithium iron phosphate battery stocks.

Are LiFePO4 batteries toxic?

The materials used in LiFePO₄ battery packs, such as iron, phosphorus, and lithium, are relatively non - toxic compared to some of the heavy metals and toxic chemicals used in other battery chemistries.

What is lithium hexafluorophosphate in a LiFePO4 battery pack?

The electrolyte in a LiFePO₄ battery pack serves as the medium for the transport of lithium ions between the anode and the cathode. It is typically composed of a lithium - containing salt dissolved in an organic solvent. Lithium hexafluorophosphate (LiPF₆) is a commonly used salt in the electrolyte.

What is a LiFePO4 battery pack?

LiFePO₄ battery packs play a vital role in storing the excess electricity generated during peak production times for use during periods of low generation. In a solar - powered home energy storage system, a LiFePO₄ battery pack can store the electricity generated by solar panels during the day.

Why do electric buses use LiFePO4 battery packs?

In addition, the long cycle life of LiFePO₄ battery packs means that the battery can maintain its performance over a long period, reducing the total cost of ownership for the EV. In electric buses, the long cycle life of LiFePO₄ battery packs is particularly beneficial.

Why is LiFePO4 a good battery?

The long cycle life is attributed to the stability of the LiFePO₄ crystal structure. The reversible lithium - ion insertion and extraction processes cause minimal structural changes in the cathode material, which helps to maintain the battery's performance over a large number of cycles.

Learn More

- 60kwh lithium iron phosphate battery pack price

- 48v 10a lithium iron phosphate battery pack

- Lithium iron phosphate power battery pack

- New 60v lithium iron phosphate battery pack

- Export lithium iron phosphate battery pack factory

- Minimum allowable voltage of lithium iron phosphate battery pack

- Rwanda lithium iron phosphate battery pack

- 36v12ah lithium iron phosphate battery pack

- What is the price of lithium iron phosphate battery pack

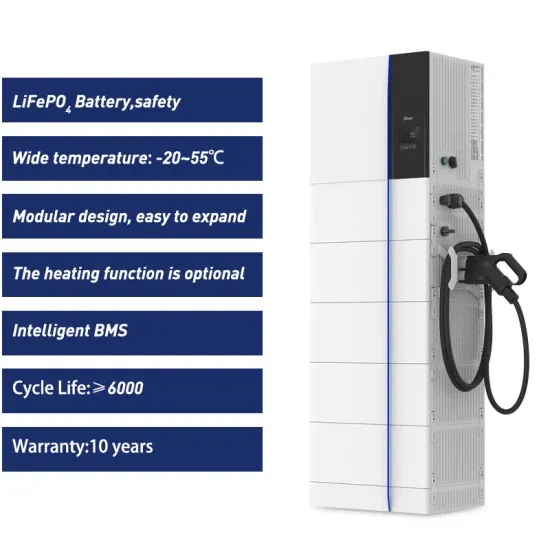

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.