What Is the Lithium Iron Phosphate Battery Price?

Jun 17, 2024 · LiFePO4 battery combines lithium materials like lithium, cobalt, nickel, and graphite. The prices of materials like lithium cobalt oxide (LCO) are

How much does a lithium iron phosphate battery cost

How much does a lithium iron phosphate battery cost? Lithium Iron Phosphate (LFP) batteries,which are often used as a power source in RVs,boats,and electric scooters,cost

The Cost of Lithium Iron Phosphate Energy Storage: What

Oct 26, 2022 · Let''s face it: lithium iron phosphate (LFP) batteries are the "reliable best friend" of the energy storage world. While they might not grab headlines like flashy new tech, their cost

Lithium-Ion Battery Pack Prices Hit Record Low

Nov 26, 2023 · The industry continues to switch to the low-cost cathode chemistry known as lithium iron phosphate (LFP). These packs and cells had the lowest

Everything You Need to Know About LiFePO4 Battery Cells: A

Apr 18, 2025 · Complete Guide to LiFePO4 Battery Cells: Advantages, Applications, and Maintenance Introduction to LiFePO4 Batteries: The Energy Storage Revolution Lithium Iron

How much does a 1kwh lithium iron phosphate battery

How much does a lithium phosphate battery cost? ickel manganese cobalt oxide ones NMCs costing 20% more. A higher concentration of e ergy cells is efficient but takes a toll on your

What Determines Rack Battery Cost per kWh in 2025?

Mar 12, 2025 · Lithium iron phosphate (LFP) batteries now cost $97/kWh at pack level, 18% cheaper than nickel-cobalt-aluminum (NCA) variants. Higher-capacity rack systems (100

How Does A Lithium Iron Phosphate Battery Work?

May 26, 2025 · Lithium Iron Phosphate (LiFePO4) batteries operate through the movement of lithium ions between a cathode made of LiFePO4 and a graphite anode during

LiFePO4 Battery Life: How Long Do They Really

May 5, 2025 · Discover how long LiFePO4 batteries REALLY last, what affects their lifespan & simple care tips to extend battery life for your marine, RV, or

Cost Projections for Utility-Scale Battery Storage: 2023

Jul 25, 2023 · Executive Summary In this work we describe the development of cost and performance projections for utility-scale lithium-ion battery systems, with a focus on 4-hour

What Are LiFePO4 Lithium Iron Phosphate Battery Packs and How Do

Feb 26, 2025 · LiFePO4 (lithium iron phosphate) battery packs are rechargeable energy storage systems using lithium-ion chemistry with a phosphate-based cathode. They offer high thermal

Lithium Iron Phosphate batteries – Pros and

Mar 25, 2021 · Introduction: Offgrid Tech has been selling Lithium batteries since 2016. LFP (Lithium Ferrophosphate or Lithium Iron Phosphate) is currently our

Visualized: How Much Do EV Batteries Cost?

Oct 15, 2023 · Both contain significant nickel proportions, increasing the battery''s energy density and allowing for longer range. At a lower cost are lithium iron

Cost Factors and Economic Viability of LiFePO4

Oct 11, 2024 · Lithium Iron Phosphate (LiFePO4) batteries are gaining attention for their performance and safety benefits, but understanding their cost factors

Lithium Iron Phosphate (LiFePO4) Energy Storage Systems

Feb 9, 2025 · Average cell-level costs for LiFePO4 batteries dropped below $80/kWh in 2023, a 40% reduction compared to 2020 figures. This positions the chemistry as 15-20% cheaper

HOW MUCH DOES A SQUARE LITHIUM IRON PHOSPHATE ENERGY STORAGE BATTERY COST

What is the lithium iron phosphate battery market? The lithium iron phosphate battery market is segmented into industrial, automotive and energy storage based on end use, The automotive

How Much Do Lithium Iron Phosphate Batteries Cost

Oct 26, 2022 · Let''s face it: lithium iron phosphate (LFP) batteries are the "reliable best friend" of the energy storage world. While they might not grab headlines like flashy new tech, their cost

how much does lithium iron phosphate energy storage cost

Based on cost and energy density considerations, lithium iron phosphate batteries, a subset of lithium-ion batteries, are still the preferred choice for grid-scale storage.

What Determines Lithium Iron Phosphate Battery Prices?

Mar 7, 2025 · Lithium iron phosphate (LiFePO4) battery prices depend on raw material costs, production scale, energy density, and market demand. They typically range from $150 to $500

How Much Do Lithium Iron Phosphate Batteries Cost?

Mar 9, 2023 · To provide a clearer picture of the costs associated with lithium iron phosphate batteries, we present a detailed breakdown based on capacity: Charger Costs: A quality

How Do Lithium Iron Phosphate Battery Packs Work and

Lithium iron phosphate (LiFePO4) battery packs are a type of rechargeable battery known for their safety, longevity, and environmental friendliness. They operate by transferring lithium ions

6 FAQs about [How much does a 80KWh lithium iron phosphate battery pack cost]

How much do lithium iron phosphate batteries cost?

How Much do Lithium Iron Phosphate Batteries Cost Per Kwh? The average cost of lithium iron phosphate (LiFePO4) batteries typically ranged from £140 to £240 per kilowatt-hour (kWh).

How much does a LiFePO4 battery cost?

Raw Material LiFePO4 battery combines lithium materials like lithium, cobalt, nickel, and graphite. The prices of materials like lithium cobalt oxide (LCO) are around $50 to $60 per kg, lithium iron phosphate (LFP) costs around $15 to $20 per kg, and lithium nickel manganese cobalt oxide (NMC) costs $25 to $35 per kg.

How will competition affect lithium iron phosphate battery prices?

Market Competition: The entry of new players and increased competition in the LiFePO4 battery market can put downward pressure on prices. Industry experts predict that lithium iron phosphate battery price per kWh could decrease by 30-50% over the next five to ten years.

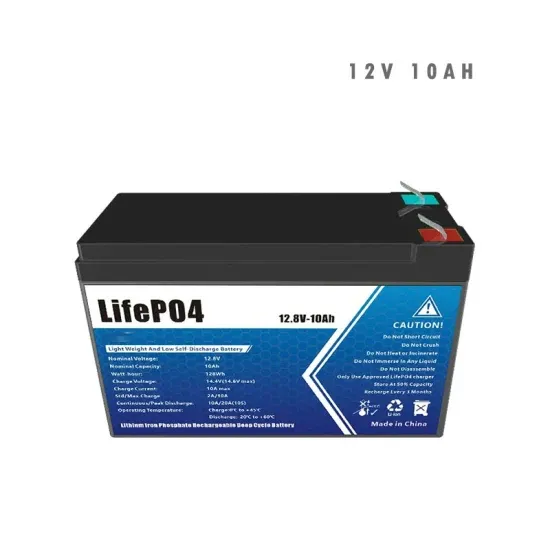

What is a lithium iron phosphate battery?

A Lithium Iron Phosphate (LiFePO4 | LFP) battery is a type of rechargeable lithium-ion battery that utilizes iron phosphate as the cathode material. They are known for their long cycle life, high thermal stability, and enhanced safety compared to other lithium-ion chemistries.

How much does a lithium carbonate battery cost?

Similarly, the price for lithium carbonate has fallen from a high of approximately $70,000 per metric ton to well below $15,000 in 2024. This article focuses primarily on two of the most sought-after Li-ion battery cathode chemistries in the automotive industry today — NCM811 and lithium iron phosphate (LFP) batteries.

What is a 80kWh battery?

The 80kWh battery meets energy needs for residential, commercial, emergency, and industrial applications. Price: Click The Button Below To Get A Discount Price. The 80kWh battery pack consists of five 16kWh LiFePO4 battery modules.

Learn More

- 48v 10a lithium iron phosphate battery pack

- Lithium iron phosphate power battery pack

- How to check the model of lithium iron phosphate battery station cabinet

- 36v12ah lithium iron phosphate battery pack

- Cylindrical lithium iron phosphate battery has high cost performance

- What is the price of lithium iron phosphate battery pack

- Light truck lithium iron phosphate battery pack

- Lithium battery pack and lithium iron phosphate prices in Mozambique

- How much does the Dakar lithium battery pack cost

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.