An electrochemical–thermal model based on dynamic responses for lithium

Jun 1, 2014 · In this paper, an electrochemical–thermal model based dynamic materials response for lithium iron phosphate battery is developed by employing the comprehensive dynamic

Lithium iron phosphate (LFP) batteries in EV cars

Apr 3, 2024 · Lithium iron phosphate batteries are a type of rechargeable battery made with lithium-iron-phosphate cathodes. Since the full name is a bit of a mouthful, they''re commonly

Estimating the tipping point for lithium iron phosphate batteries

Jan 1, 2025 · Our model – which considers tradeoffs between battery capacity and weight – enumerates a range ''tipping point'' of 373.52 miles, beyond which NMC batteries consistently

Modeling and Experimental Evaluation of Lithium Iron Phosphate Battery

Oct 23, 2022 · The main objective of this paper is to present lithium iron phosphate battery modeling and experimental evaluation. The modeling of the battery was performed us

Past and Present of LiFePO4: From Fundamental Research to

Jan 10, 2019 · In this overview, we go over the past and present of lithium iron phosphate (LFP) as a successful case of technology transfer from the research bench to commercialization. The

State-of-Charge Estimation for Lithium Iron Phosphate Batteries

May 18, 2025 · The accuracy of State-of-Charge (SOC) estimation is a key concern in the application of Lithium Iron Phosphate (LFP) batteries. In this paper, a novel SOC estim

Optimum Selection of Lithium Iron Phosphate Battery Cells

Mar 20, 2025 · This paper presents a systematic approach to selecting lithium iron phosphate (LFP) battery cells for electric vehicle (EV) applications, considering cost, volume, aging

Reliability assessment and failure analysis of lithium iron phosphate

Feb 20, 2014 · Analysis of the reliability and failure mode of lithium iron phosphate batteries is essential to ensure the cells quality and safety of use. For this purpose, the paper built a

Electro-thermal analysis of Lithium Iron Phosphate battery

Mar 1, 2014 · In this work, an empirical equation characterizing the battery''s electrical behavior is coupled with a lumped thermal model to analyze the electrical and thermal behavior of the

Lithium iron phosphate battery

A lithium iron phosphate battery is a type of lithium-ion battery that utilizes iron phosphate as its cathode material. It is known for its longer lifespan and high peak power rating in comparison

Parameter Identification of Lithium Iron Phosphate Battery Model

Dec 1, 2019 · The joint simulation of lithium iron phosphate battery discharging based on NEDC operating condition was carried out by using MATLAB and ADVISOR software. The lithium

Production process of lithium iron phosphate

Jul 11, 2024 · 1. Lithium iron phosphate production process: Lithium iron phosphate is a multifunctional new lithium-ion battery system. Its safety, endurance and cycle life are much

Parameter Identification of Lithium Iron Phosphate Battery Model

Dec 1, 2019 · According to the characteristics of lithium iron phosphate battery in charging and discharging process, the data of open circuit voltage change during battery test were used to

Lithium‑iron-phosphate battery electrochemical modelling under

Feb 1, 2021 · This work models and simulates lithium‑iron-phosphate batteries under ambient temperatures ranging from 45 °C to −10 °C. Essential modifications based on an existing

Lithium‑iron-phosphate battery electrochemical modelling under

Feb 1, 2021 · A lithium‑iron-phosphate battery was modeled and simulated based on an electrochemical model–which incorporates the solid- and liquid-phase diffusion and ohmic

Research on Modeling and SOC Estimation of Lithium Iron Phosphate

Oct 1, 2018 · Firstly, taking into account the effects of temperature on available battery capacity, open-circuit voltage, ohm resistance, and polarization parameters, this article constructed a

Lithium iron phosphate – Knowledge and References –

Lithium iron phosphate (LiFePO4 or LFP) is a type of cathode composition used in lithium-ion batteries that was developed to address the challenges of thermal and structural instability. It

6 FAQs about [How to check the model of lithium iron phosphate battery station cabinet]

Is lithium iron phosphate battery suitable for low temperature and small rate discharge?

Firstly, taking into account the effects of temperature on available battery capacity, open-circuit voltage, ohm resistance, and polarization parameters, this article constructed a new battery model suitable for low temperature and small rate discharge conditions based on the lithium iron phosphate battery that used in the project.

What is the nominal capacity of lithium iron phosphate batteries?

The data is collected from experiments on domestic lithium iron phosphate batteries with a nominal capacity of 40 AH and a nominal voltage of 3.2 V. The parameters related to the model are identified in combination with the previous sections and the modeling is performed in Matlab/Simulink to compare the output changes between 500 and 1000 circles.

Why does a lithium phosphate battery have a limited service life?

A battery has a limited service life. Because of the continuous charge and discharge during the battery’s life cycle, the lithium iron loss and active material attenuation in the lithium iron phosphate battery could cause irreversible capacity loss which directly affects the battery’s service life.

Can layered circuit model fit a lithium iron phosphate (LFP) cell data set?

The layered approach was successful in fitting an equivalent circuit model to a lithium iron phosphate (LFP) cell data set to within a mean of 0.7mV residual error, and max of 9.2mV error at a transient. Content may be subject to copyright.

How are lithium battery cells modeled?

Lithium battery cells are commonly modeled using an equivalent circuit with large lookup tables for each circuit element, allowing flexibility for the model to closely match measured data. Pulse discharge curves and charge curves are collected experimentally to characterize the battery performance at various operating points.

What is lithium iron phosphate battery?

Finally, Section 6 draws the conclusion. Lithium iron phosphate battery is a lithium iron secondary battery with lithium iron phosphate as the positive electrode material. It is usually called “rocking chair battery” for its reversible lithium insertion and de-insertion properties.

Learn More

- How long does it take for the lithium iron phosphate battery station cabinet to charge the base station

- How to install lithium iron phosphate battery station cabinet

- Can the lithium iron phosphate battery station cabinet be used at low temperatures

- Liquid-cooled energy storage lithium iron phosphate battery station cabinet

- Lithium iron phosphate battery station cabinet 10 kWh

- How long can the lithium iron phosphate battery of the energy storage cabinet be used

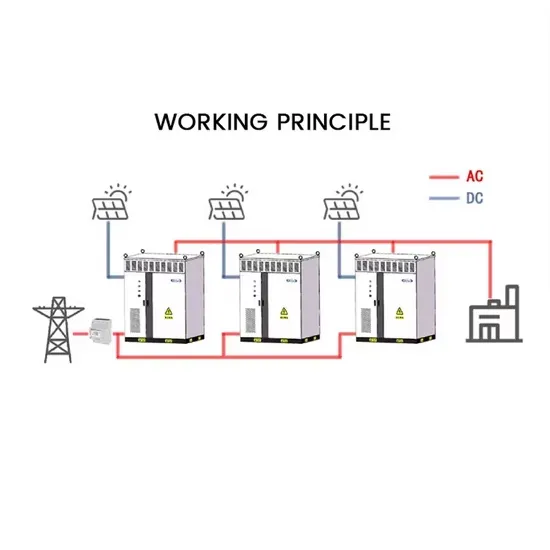

- How to change the lithium battery station cabinet to photovoltaic power supply

- Lithium iron phosphate battery service life of energy storage cabinet

- Tajikistan lithium iron phosphate battery energy storage container

Industrial & Commercial Energy Storage Market Growth

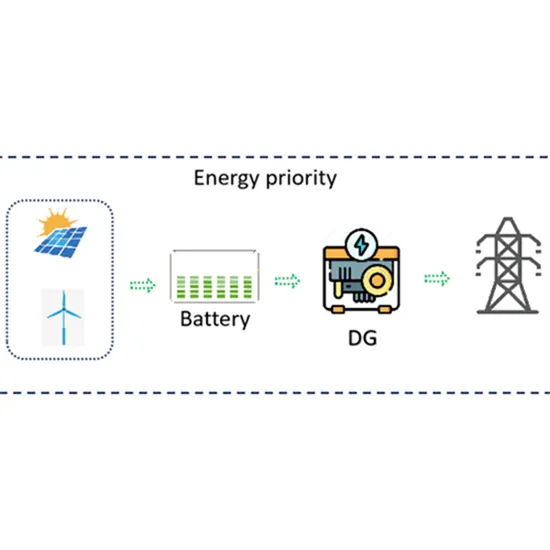

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.