How much does a lithium battery pack cost

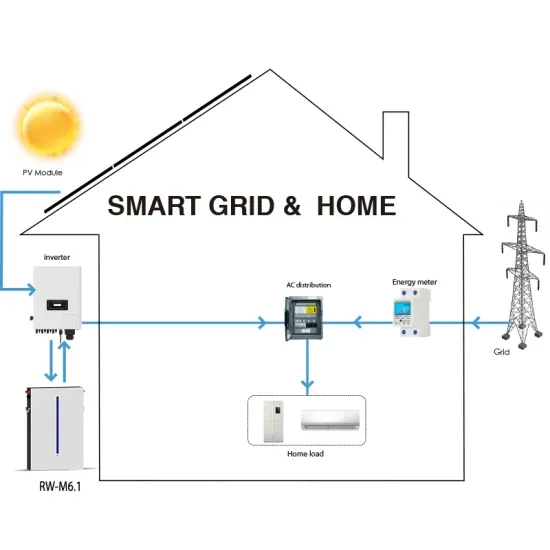

As the photovoltaic (PV) industry continues to evolve, advancements in How much does a lithium battery pack cost have become critical to optimizing the utilization of renewable energy

An Estimate: Cost of New EV Car Battery Packs In

Jun 22, 2024 · The battery price of an electric car will vary, but for a safe range, the average cost of 1 kWh is around 15000 to 20,000 rupees. Based on this

Lithium-Ion Battery Costs: Manufacturing Prices,

Mar 16, 2025 · The cost to make lithium-ion batteries ranges from $40 to $140 per kWh. Prices depend on battery chemistry, like LFP or NMC, and geography, such as China or the West.

How Much Does a Lithium Ion Battery Cost? A Complete

Feb 13, 2025 · Electric Vehicle Batteries: The cost of lithium-ion batteries for electric vehicles is significantly higher, typically ranging from $5,000 to $15,000 for a complete battery pack.

Lithium-Ion Battery Costs: Price Trends, Factors, and Current

Dec 31, 2024 · Lithium-ion battery costs vary widely. Prices range from $10 to $20,000 based on use. Electric vehicle batteries average $4,760 to $19,200. Solar batteries typically cost

How Much Is A Tesla Model S Battery Cost? Breakdown

Mar 17, 2025 · Battery Pack Cost The battery pack cost is the most significant component of the overall battery cost. The Tesla Model S battery pack is a lithium-ion battery pack that consists

How much does the energy storage battery pack cost?

Aug 19, 2024 · A myriad of components determines the financial outlay associated with energy storage battery packs. These components encompass the type of battery (e.g., lithium-ion,

How Much Does A 100kWh Battery Cost?

May 26, 2025 · 100kWh battery systems typically cost between $10,000 and $30,000, depending on chemistry, application, and scale. Lithium-ion variants like NMC or LiFePO4 dominate the

How much does a solar light battery pack cost | NenPower

Jul 4, 2024 · The cost of a solar light battery pack typically ranges from $20 to $100, influenced by factors such as capacity, brand reputation, and additional features. A thorough examination of

Electric Car Battery Pack Costs: How Much They Are And

Mar 27, 2025 · The cost of an electric car battery pack varies widely. Replacement costs range from $4,000 to $20,000, depending on the manufacturer''s specifications.

Dakar large single lithium battery pack

dealer and supplier of lithium batteries in Senegal. Our expertise lies in the manufacturing and supplying of lithium batteries, which enable us to provide affordable and reliable lithium battery

Where are EV battery prices headed in 2025 and

3 days ago · Lithium-ion (Li-ion) EV battery prices have decreased dramatically over the past few years, mainly due to the fall in prices of critical battery

How Much Is An Electric Car Battery Pack? Cost Breakdown

Mar 29, 2025 · The cost of an electric car battery pack is a complex topic, influenced by several factors, including the type of battery chemistry, the size and capacity of the battery, the

Battery Pack Costs: Trends, Replacement Expenses, and Price

Mar 15, 2025 · The cost of a battery pack varies significantly. Lithium-ion batteries can range from $10 to $20,000 based on the device type. Electric vehicle batteries typically cost between

Prices of Lithium Batteries: A Comprehensive Analysis

Apr 11, 2025 · Lithium battery prices fluctuate due to raw material costs (e.g., lithium, cobalt), manufacturing innovations, geopolitical factors, and demand surges from EVs and renewable

How Much Is Tesla Battery? Cost Breakdown | CarsBibles

Apr 19, 2025 · At the heart of every Tesla lies its powerful and sophisticated battery pack, a technological marvel that propels these vehicles forward. But how much does this crucial

Dakar Battery Pack Enterprise Powering West Africa s Energy

Why Battery Storage Matters in West Africa''s Energy Landscape With 60% of Senegal''s population under 25 and urbanization rates climbing 4% annually, Dakar battery pack

6 FAQs about [How much does the Dakar lithium battery pack cost]

How much does a battery pack cost in India?

It has been seen that, the batteries with higher kWh capacities are more expensive and while the batteries with lower kWh capacities are less expensive. So, in general, if we talk about India, then 1 kWh of a battery pack costs you around 15,000 to 20,000 rupees. Again, this price depends on the brand you choose and the quality of the battery.

How much does a lithium battery cost in 2024?

In 2024, the average global prices of lithium-ion batteries dropped by 20%, reaching $115 per kWh. For electric vehicle batteries, the price fell below $100 per kWh Why Are Lithium Battery Prices Falling?

How much does a lithium ion battery cost?

The electric vehicle market, the primary driver for lithium-ion batteries, grew more slowly than in previous years but still showed the lowest price at $97 per kWh. Meanwhile, the stationary storage market has surged, with intense competition among cell and system suppliers, particularly in China.

How much does a lithium battery cost in China?

Meanwhile, the stationary storage market has surged, with intense competition among cell and system suppliers, particularly in China. Regionally, the average prices of lithium battery packs were lower in China, at $94 per kWh, while prices in the U.S. and Europe were 31% and 48% higher, respectively.

How much does an EV battery pack cost?

Depending on the brand and model of the vehicle, the cost of a new lithium-ion battery pack might be as high as $25,000: The price of an EV battery pack can be shaped by various factors such as raw material costs, production expenses, packaging complexities, and supply chain stability. One of the main factors is chemical composition.

How much does a lithium phosphate battery cost?

At a lower cost are lithium iron phosphate (LFP) batteries, which are cheaper to make than cobalt and nickel-based variants. LFP battery cells have an average price of $98.5 per kWh. However, they offer less specific energy and are more suitable for standard- or short-range EVs.

Learn More

- How much does a 80KWh lithium iron phosphate battery pack cost

- How much does it cost to add a lithium battery pack in Barcelona Spain

- How much does a lithium battery pack cost per kilowatt-hour

- How much can I buy a UL lithium battery pack

- How much does it cost to transport lithium battery energy storage cabinets by air

- How much is the 72V lithium battery pack

- How much does a lithium battery cost in an energy storage cabinet

- How much is the Nordic lithium battery pack

- How many mAh does a lithium battery pack usually use

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.