1MWh Battery Energy Storage System Prices

Jan 6, 2025 · For example, if there is a significant increase in the cost of lithium or other key battery materials, it could put upward pressure on battery prices and, consequently, on the

Where are EV battery prices headed in 2025 and

3 days ago · Lithium-ion (Li-ion) EV battery prices have decreased dramatically over the past few years, mainly due to the fall in prices of critical battery

Battery Pack Costs: Trends, Replacement Expenses, and Price

Mar 15, 2025 · The cost of a battery pack varies significantly. Lithium-ion batteries can range from $10 to $20,000 based on the device type. Electric vehicle batteries typically cost between

How Much Do Lithium-Ion Batteries Cost? An Insight into

Feb 21, 2025 · Currently, lithium-ion battery prices have dropped significantly, with average costs reaching around $139 per kilowatt-hour (kWh) in 2023, marking a substantial decrease from

Lithium-Ion Battery Costs: Price Trends, Factors, and Current

Dec 31, 2024 · Electric vehicle batteries average $4,760 to $19,200. Solar batteries typically cost between $6,800 and $10,700. Costs depend on device type and various market factors like

Cost Projections for Utility-Scale Battery Storage: 2023

Jul 25, 2023 · Executive Summary In this work we describe the development of cost and performance projections for utility-scale lithium-ion battery systems, with a focus on 4-hour

Battery Costs in 2020-2030: How Much Have Prices Dropped

Aug 6, 2025 · The price of batteries is one of the biggest factors affecting the growth of electric vehicles (EVs) and energy storage. Over the past decade, battery prices have fallen

How Much Does a Lithium Battery Cost in 2025

Dec 9, 2024 · The price per kilowatt-hour (kWh) is a fundamental factor in calculating the total cost of ownership (TCO) for lithium ion batteries. Currently, the average lithium ion battery cost

Electric Car Battery Replacement Cost in India for 2024

Nov 7, 2024 · This question is challenging to answer. Several components affect the EV battery replacement cost in India. The factors are: Car make and model: What type of EV do you

Understanding Lithium Battery Costs: What You Need to Know Per kWh

Feb 11, 2025 · As of 2023, the average cost of lithium-ion batteries has seen a steady decline, estimated at around $130 to $150 per kilowatt-hour. This reduction in price is primarily

Lithium-Ion Battery Pack Prices See Largest Drop Since

Dec 10, 2024 · Lithium-ion battery pack prices dropped 20% from 2023 to a record low of $115 per kilowatt-hour, according to analysis by research provider BloombergNEF (BNEF). Factors

6 FAQs about [How much does a lithium battery pack cost per kilowatt-hour ]

How much does a lithium ion battery cost?

The average price of a lithium-ion battery pack is down to $209/kilowatt-hour. The price decline is due to a growing battery manufacturing industry with significant economies of scale starting to bring costs down.

What is the cost of a lithium ion battery pack?

Thanks in part to our efforts, the cost of a lithium ion battery pack dropped from $900/kWh in 2011 to less than $140/kWh in 2020. We’re looking to build on that progress in the years ahead.

Why did lithium-ion battery prices drop 20% from 2023?

Lithium-ion battery pack prices dropped 20% from 2023 to a record low of $115 per kilowatt-hour, according to analysis by research provider BloombergNEF (BNEF). Factors driving the decline include cell manufacturing overcapacity, economies of scale, low metal and component prices, adoption of lower-cost lithium-...

How much does an 80 kWh battery cost?

A more popular 80-kWh pack would be $11,120. Considering a $35,000-$40,000 price tag for a car, it's still a substantial part of the price, but let's also recall that over 10 years ago, in a similar bracket, we would get only an EV with a 24-30-kWh battery and a few times shorter driving range.

How much does a kilowatt-hour of EV battery cost?

A kilowatt-hour of usable EV battery capacity cost $139 in 2023, and using 2023 constant dollars, it was $1,415/kWh in 2008. That's a huge drop in battery cost. The report says that a kilowatt-hour of usable EV battery capacity costs about $139 in 2023, and using 2023 constant dollars, it was $1,415/kWh in 2008.

How much does a 75 kWh battery cost?

The value of USD 115 per kilowatt hour at the pack level comes from BloombergNEF’s annual analysis of battery prices. For the study, the experts at BNEF analysed 343 ‘data points’ (i.e. known battery prices) from electric cars, electric buses and electric trucks. At 115 USD/kWh, a 75-kWh battery would cost 8,625 dollars or about 8,220 euros.

Learn More

- How much does it cost to add a lithium battery pack in Barcelona Spain

- How much does a 80KWh lithium iron phosphate battery pack cost

- How much does the Dakar lithium battery pack cost

- How much electricity can the Czech Brno lithium battery pack store

- How much does Haiti s lithium battery cost

- How much can I buy a UL lithium battery pack

- How much is the 72V lithium battery pack

- How much does a new energy battery cabinet cost per kilowatt-hour

- How much does a lithium battery cost

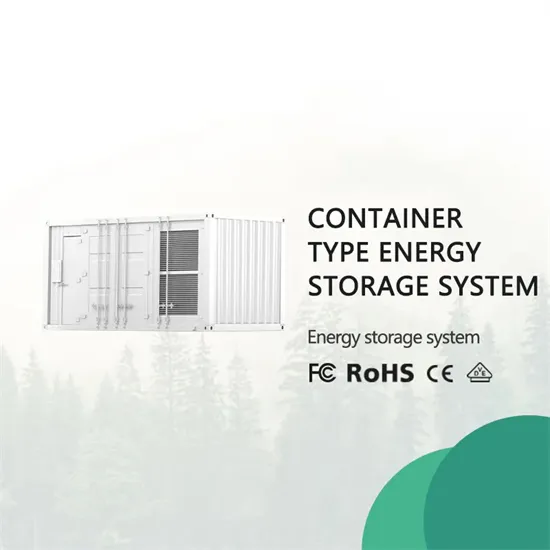

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

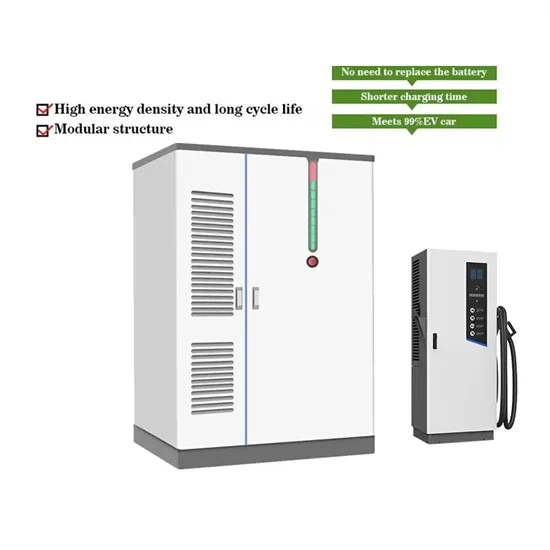

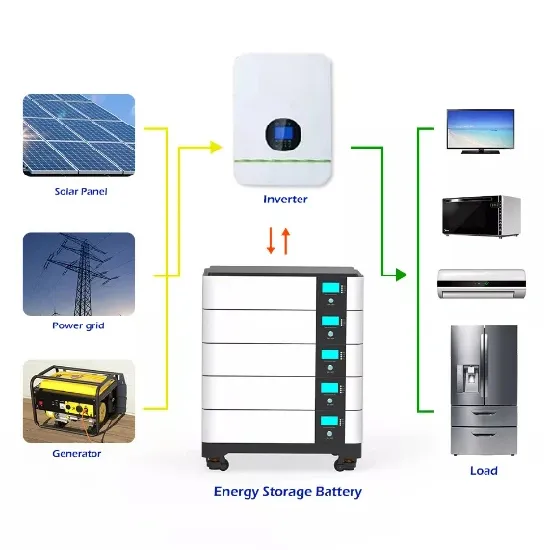

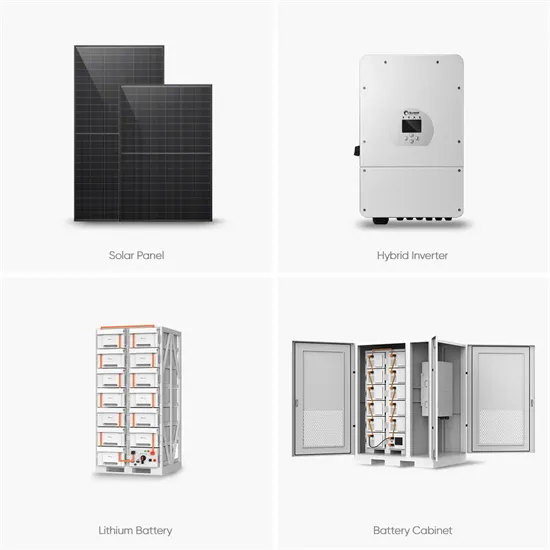

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.