EV battery costs set to spike as raw material

May 18, 2022 · The cost to produce electric vehicles is primed to surge over the next four years, according to a new report, the result of scarcity in key raw

How To Estimate The Costs To Start A Lithium

Apr 17, 2025 · Key startup costs include initial investments such as land purchase or lease, factory construction, and machinery setup. Explore What Is the True

How to Ship Lithium-Ion Batteries in 2024 | Easyship

Jul 15, 2025 · With so many products using lithium batteries, it''s important to understand how to ship them. Learn here how to safely pack and ship lithium batteries.

Cost of Lithium Batteries (15 Solar Brands

Jun 9, 2021 · In 2025, the cost of lithium batteries like LiFePO4 is going down while their durability is increasing. Now is the perfect time to replace your lead

How Manufacturer Can Tell You About Cost of

Jun 6, 2024 · What makes lithium-ion batteries more expensive? To know the real truth behind the costly price sticker of a lithium battery, we need to understand

Study reveals plunge in lithium-ion battery costs

Mar 23, 2021 · The cost of lithium-ion batteries for phones, laptops, and cars has plunged over the years, and an MIT study shows just how dramatic that drop

Battery Pack Certifications – Costs, Timelines and Key

The result: a faster path to market, reduced costs, and total confidence in your product''s compliance. Lithium battery safety is at the top of the list for anyone who manufactures custom

Trends in batteries – Global EV Outlook 2023 –

Aug 19, 2025 · Trends in batteries Battery demand for EVs continues to rise Automotive lithium-ion (Li-ion) battery demand increased by about 65% to 550

Top 8 Lithium Ion Battery Suppliers in Spain 2025

May 16, 2025 · With the rapid spread of renewable energy, lithium batteries are playing an increasingly important role in modern life and various industries. Some time ago, the large

Understanding solar battery costs: Guide for homeowners in Spain

Mar 6, 2024 · Solar energy offers a sustainable solution to power homes, but what about when the sun goes down? Enter solar batteries, which store electricity generated by solar panels for

How to calculate the lithium content in a battery

May 3, 2024 · When considering ''lithium content'', this does not necessarily mean how much lithium metal is in the battery. Technological advances have come up with new alloys to

Battery Pack Costs: Trends, Replacement Expenses, and Price

Mar 15, 2025 · The cost of a battery pack varies significantly. Lithium-ion batteries can range from $10 to $20,000 based on the device type. Electric vehicle batteries typically cost between

Historical and prospective lithium-ion battery cost

Jan 15, 2024 · Lithium-ion batteries (LiBs) are pivotal in the shift towards electric mobility, having seen an 85 % reduction in production costs over the past decade. However, achieving even

Potential out-of-warranty cost for Rav4 Prime Lithium-Ion battery pack

Jun 4, 2022 · Hi all, I was wondering if something unfortunate happened, and a battery pack were damaged, due to moisture or ventilation issues that would put it out of warranty, how much

Lithium-Ion Battery Production Is Surging, but at What Cost?

Sep 20, 2017 · Lithium-Ion Battery Production Is Surging, but at What Cost? Gigafactories intended to scale the production of electric-vehicle batteries can exact a human toll.

FOTW #1272, January 9, 2023: Electric Vehicle

Jun 20, 2017 · The Department of Energy''s (DOE''s) Vehicle Technologies Office estimates the cost of an electric vehicle lithium-ion battery pack declined 89%

U.S. Tariffs on Chinese Lithium Batteries: Full Breakdown

Apr 15, 2025 · U.S. tariffs on Chinese lithium batteries have become a critical factor shaping the global battery market in 2025. These tariffs directly impact lithium-ion batteries'' cost, supply

Battery Pack Certifications – Costs, Timelines and Key

May 28, 2025 · Custom lithium battery packs are not off-the-shelf components. They are engineered systems—built to meet your exact voltage, capacity, safety, and integration needs.

How much does lithium battery energy storage cost?

Aug 3, 2024 · Determining the expenditure associated with lithium battery energy storage involves several factors, including 1. the type of lithium battery, 2. installation and maintenance costs, 3.

How Much Does an OEM Custom Battery Cost? Factors,

Feb 18, 2024 · How Much Does an OEM Custom Battery Cost? Factors, Comparisons & Savings TipsOEM custom battery costs range from $50 to $500+ per unit, depending on capacity,

6 FAQs about [How much does it cost to add a lithium battery pack in Barcelona Spain]

How much does a lithium ion battery cost?

Lithium ion battery costs range from $40-140/kWh, depending on the chemistry (LFP vs NMC), geography (China vs the West) and cost basis (cash cost, marginal cost and actual pricing). This data-file is a breakdown of lithium ion battery costs, across c15 materials and c20 manufacturing stages, so input assumptions can be stress-tested.

How are materials costs of lithium ion batteries calculated?

The breakdown covers 25 categories (e.g., lithium, nickel, graphite), across 10 different battery chemistries (e.g., NCA, NMC, LFP and others, chart below). Materials costs of lithium ion batteries can be calculated by comparing our mass balances above with the costs of different input commodity prices.

Are lithium batteries regulated?

Shipping batteries is highly regulated, and anyone involved in packaging or handling battery shipments must complete annual certification training. These regulations apply to all lithium battery types and are strictly enforced by agencies such as DOT, IATA, and IMDG.

What are the shipping regulations for lithium batteries?

The U.S. DOT (United States Department of Transportation) defines shipping regulations for the U.S. under 49 CFR, Sections 100 - 185. Section 173.185 specifically addresses specifications and exceptions and packaging for lithium batteries; section 172.101 covers shipping.

Can lithium batteries be shipped by air freight?

New regulations were passed in 2016 that tighten requirements for shipments of lithium products and that forbid lithium batteries to be shipped on passenger aircraft. It is been projected by some that shipping lithium by air freight together may eventually become forbidden.

What are the IEC standards for lithium batteries?

IEC standards address general, safety, and transportation specifications. For lithium batteries, key standards are: IEC 62133: Secondary cells and batteries containing alkaline or other non-acid electrolytes – safety requirements for portable sealed secondary cells and for batteries made from them, for use in portable applications.

Learn More

- How much does a 80KWh lithium iron phosphate battery pack cost

- How much does the Dakar lithium battery pack cost

- How much can I buy a UL lithium battery pack

- Lg cylindrical lithium battery in Barcelona Spain

- How much does Haiti s lithium battery cost

- How much electricity can the Czech Brno lithium battery pack store

- How much does a 5MWh energy storage container cost at CRRC Barcelona Spain

- 20Ah lithium battery pack

- Lithium battery pack voltage-balanced adjustable power supply

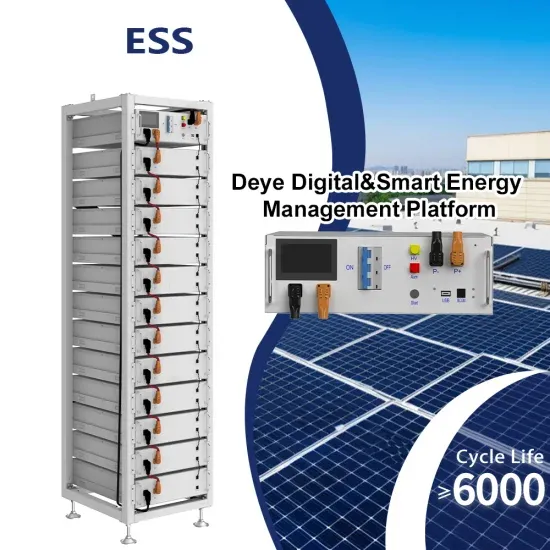

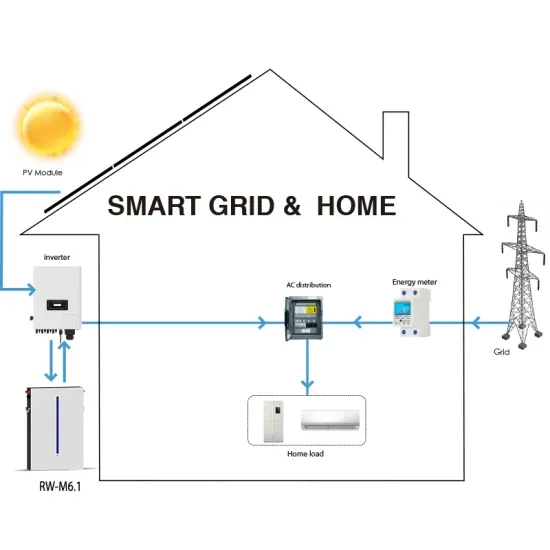

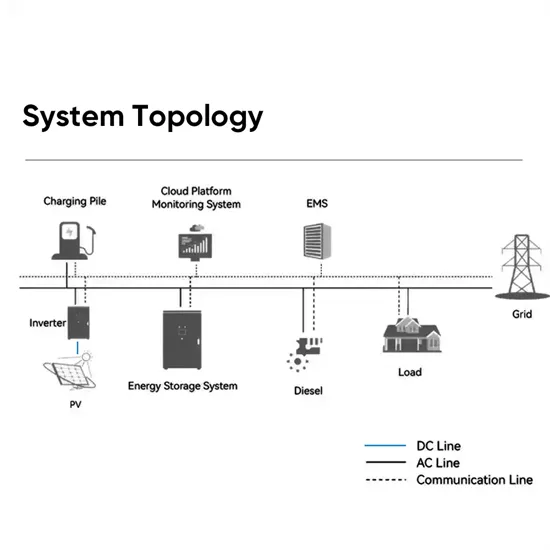

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

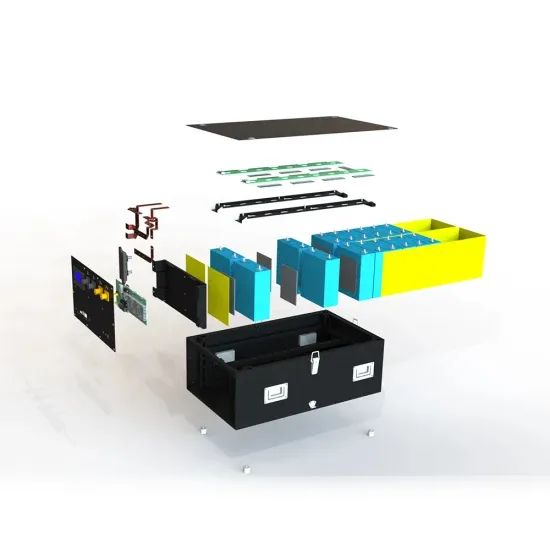

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.