Lithium-Ion Information Guide | Houston, Texas USA

Lithium-Ion Information Guide - Technology ProfileBattery packs built to customer specifications using Lithium-Ion and Lithium-Polymer cells have been Designed and Developed at SWE for

Lithium-ion Battery Cells and Chemistries: The

Aug 28, 2022 · Lithium-ion Cell Formats The lithium battery pack, often known as the assembly of different components, contains individual cells. These cells

Lithium Battery Voltage Guide: Types, Charging

Jan 27, 2024 · This comprehensive guide explains key voltage characteristics of major lithium battery types, including Li-ion, LiPo, LiFePO4, and 18650 batteries, with detailed voltage

The Ultimate Guide to Lithium Battery Packs

Jun 6, 2025 · Two Basic Configurations: Series Connection: Increases voltage. Example: 3 cells of 3.7V connected in series = 11.1V output. Parallel Connection: Increases capacity. Example:

Lithium Battery Voltage Chart: 3.2V, 3.7V, 4.2V

Jan 4, 2024 · What is a Battery Voltage Chart? A battery voltage chart is a critical tool for understanding how different lithium-ion batteries perform under specific

Analysis of lithium battery voltage and its

2 days ago · This article will cover the basic principles of lithium batteries and focusing on the factors that influence lithium battery voltage and performance.

Battery pack calculator : Capacity, C-rating, ampere, charge

Battery calculator : calculation of battery pack capacity, c-rate, run-time, charge and discharge current Onlin free battery calculator for any kind of battery : lithium, Alkaline, LiPo, Li-ION,

What Are the Main Types of Lithium-ion Batteries

Jul 11, 2025 · Explore the main types of lithium-ion batteries, including LCO, NMC, LFP, NCA, LTO, and LMO, and their unique characteristics for various applications.

Understanding Lithium Battery Configurations:

Apr 18, 2025 · Building a lithium battery pack requires careful planning around voltage, amp-hour capacity, and the intended application. The arrangement of

How Many Cells in a Lithium Battery Pack? A Complete

Mar 14, 2025 · This setup meets different energy storage needs. LiFePO4, or lithium iron phosphate, is a type of lithium battery known for its stability and safety. A LiFePO4 battery

The Ultimate Guide to Lithium Battery Packs

Jun 6, 2025 · The Ultimate Guide to Lithium Battery Packs-from how they work and key types like lithium-ion to buying tips and maintenance advice. Learn to choose the right battery pack for

Pack锂电池基础知识

May 7, 2025 · 本文将全面介绍锂电池Pack的基础知识,包括锂电池Pack的电芯和相应的电池管理系统(BMS)、结构组件等。锂电池 Pack 是将多个锂电池电

A Complete Guide to Understanding Battery Packs

Jul 24, 2024 · Battery packs come in many types, each suited to different needs and applications. Whether it''s for a smartphone, electric vehicle, or a portable

A Guide to Understanding Battery Specifications

Dec 18, 2008 · Battery Basics Cell, modules, and packs – Hybrid and electric vehicles have a high voltage battery pack that consists of individual modules and cells organized in series and

What Is a Lithium-Ion Battery Pack? Types, Voltages & How

Jul 4, 2025 · Learn the differences between 18650, 21700, and custom lithium-ion battery packs. Understand voltages like 11.1V and 14.8V, and how to choose the right Li-ion battery pack for

Understanding Lithium Battery Voltage

Mar 27, 2025 · This guide provides an in-depth comparison of the key voltage characteristics of popular lithium battery types, including lithium-ion, lithium polymer, lithium iron phosphate, and

Battery Cells, Modules, and Packs: Key Differences Explained

Apr 18, 2025 · Pack Components Modules: Combined in series and parallel to achieve the desired voltage and capacity. Battery Management System (BMS): Monitors and controls the

Lithium-Ion Battery Voltage: How Many Volts And Types

Mar 15, 2025 · A lithium-ion battery has a nominal voltage of 3.7 volts per cell. When connected in series, the total voltage increases by 3.7 volts for each cell. This configuration allows for

6 FAQs about [Lithium battery pack voltage type]

How many volts is a lithium polymer battery?

Single lithium polymer (Li-Po) cells typically have a nominal voltage of 3.7 volts. When the voltage of this type of cell is charged to 4.2 volts, it is considered fully charged. During the battery discharge process, when the voltage drops to 3.27 volts, the battery is considered fully discharged.

What is the voltage of a lithium ion battery?

Common lithium-ion cells typically have a nominal voltage of about 3.6 to 3.7 volts. This range is standard for most consumer applications, including smartphones and laptops. The actual voltage can vary slightly based on the specific chemistry and design of the cell. Most lithium-ion batteries consist of multiple cells connected in series.

What should you know about lithium ion batteries?

The most important key parameter you should know in lithium-ion batteries is the nominal voltage. The standard operating voltage of the lithium-ion battery system is called the nominal voltage. For lithium-ion batteries, the nominal voltage is approximately 3.7-volt per cell which is the average voltage during the discharge cycle.

What is the SOC voltage chart for lithium batteries?

The SoC voltage chart for lithium batteries shows the voltage values with respect to SoC percentage. A Li-ion cell when fully charged at 100%SoC can have nearly 4.2V. As it starts to discharge itself, the voltage decreases, and the voltage remains to be 3.7V when the battery is at half charge, ie, 50%SoC.

What are the different types of lithium batteries?

Different types of lithium batteries have varying maximum charge voltages: Li-ion Batteries: Typically have a max charge voltage between 4.2 to 4.3 volts per cell. LiPo Batteries: Share a similar range with Li-ion batteries, ranging from 4.2 to 4.3 volts per cell.

What is lithium battery chemistry?

Lithium Battery Chemistry: Different lithium battery chemistries have distinct voltage characteristics. For instance, LiFePO4 batteries typically have a lower nominal voltage (around 3.2 volts per cell) than Li-ion batteries (about 3.6 to 3.7 volts per cell).

Learn More

- Minimum allowable voltage of lithium iron phosphate battery pack

- High voltage lithium battery pack protection solution

- Lithium battery pack voltage container

- What is the use of high voltage lithium battery pack

- Lithium battery pack medium and high voltage box

- Lithium battery pack voltage and temperature collection

- Full-charge voltage of lithium battery pack

- 24V lithium battery pack voltage

- Lithium battery pack for power supply

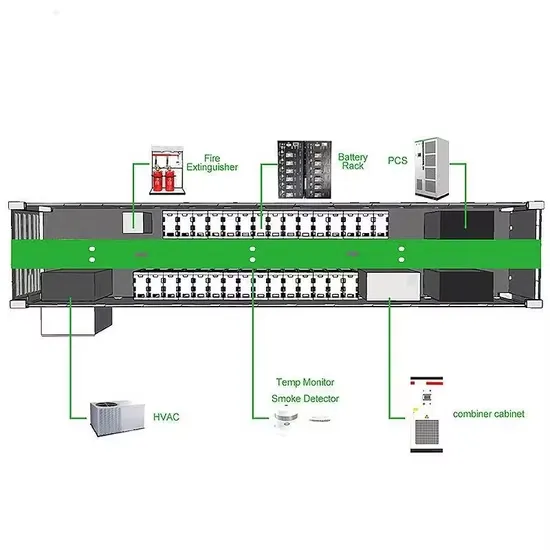

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

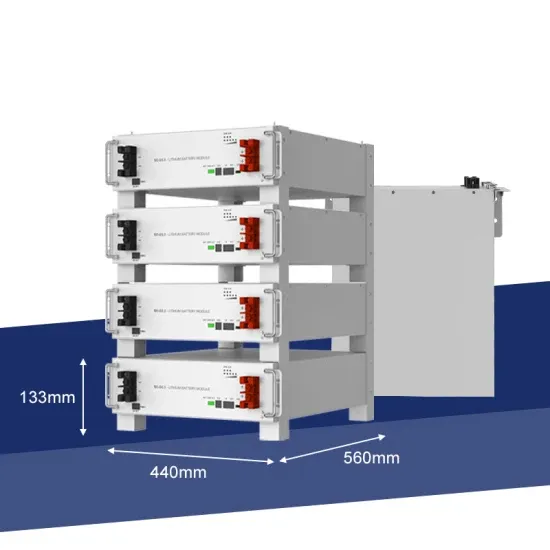

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.