Capacity and impedance characteristics of the lithium-ion battery

Capacity and impedance characteristics of the lithium-ion battery and mechanical properties of the battery pack under coupled temperature-vibration conditions: an experimental approach

Comprehensive Guide to Lithium Battery Temperature

12 hours ago · Effective lithium battery temperature management protects your battery packs from dangerous failures and costly downtime. Poor temperature management can trigger thermal

Effective Battery Energy Capacity as a Function of

May 1, 2020 · In total, the main part of our (DAQ) device includes temperature sensors for reporting ambient/object temperature, LCD display to show relevant information, 5-count AA

Temperature Prediction of Lithium Battery Packs Based on

3 days ago · To address the challenge of feature extraction and deep temporal scale mining in lithium-ion battery temperature prediction with massive data, this paper proposes a surface

Design of power lithium battery management system based

Mar 1, 2022 · Although power lithium-ion batteries are widely used, there are many problems in the process of use, such as: overcharging and discharging lead to high battery temperature

Transient Thermal Simulation of Lithium‐Ion Batteries for

Dec 9, 2024 · This paper focuses on the development of a plug-in hybrid vehicle (PHEV) full-vehicle transient thermal model in thermal modelling software to predict the battery surface

Embedded internal temperature measurement of single Lithium

Jul 30, 2025 · Using flexible thin-film thermocouple sensing technology, combined with simulation and analytical methods, the internal temperatures of representative cells in the battery pack

In-situ temperature monitoring of a lithium-ion battery

Oct 1, 2022 · Currently, many battery parameters are estimated through a combination of mathematical modelling and data collection using traditional surface-mount sensor technology

Data-driven research on battery pack temperature prediction

Jul 15, 2025 · This model not only provides precise predictions for the operating temperature of lithium-ion batteries in electric vehicles but also offers valuable insights for optimizing thermal

Improving Voltage Measurement Accuracy in Battery

Aug 22, 2023 · As reviewed in my earlier article, accurate monitoring of battery voltage, current and temperature is necessary to ensure the safe operation of battery-powered systems such

TI BATTERY MANAGEMENT SYSTEMS SEMINAR

Sep 29, 2023 · Battery electronics options Protector • Simple, hardware-based protection to respond to unsafe conditions like over-voltage, under-voltage, over-current, over-temperature,

Detailed Thermal Characterization on a 48V Lithium-Ion

Oct 6, 2023 · This study experimentally investigates the temperature distribution and behavior of a 48V Lithium-Ion (Li-ion) battery pack during two charge-discharge cycles using 25

Monitoring and control of internal temperature in power batteries

Feb 1, 2025 · The thermal characteristics and temperature sensitivity of batteries are introduced first, followed by a detailed discussion of various internal temperature monitoring technologies,

Physics-informed machine learning estimation of the temperature

Jun 15, 2025 · Accurate tracking and prediction of the temperature distribution of lithium-ion batteries provide feedback for the Battery Management System, which is crucial for ensuring

Multicell Voltage Monitoring for Lithium Battery

Mar 16, 2020 · In this article we will learn how we can measure the individual cell voltage of the cells used in a Lithium battery pack. For the sake of this project

Low temperature heating methods for lithium-ion batteries:

May 1, 2025 · However, such researches generally entail long industrialization cycles. On the contrary, the heating methods for power batteries are more suitable solution in the short term.

Lithium-ion battery pack thermal management under high

Mar 1, 2024 · To ensure the stable operation of lithium-ion battery under high ambient temperature with high discharge rate and long operating cycles, the phase cha

fenrg-2021-702139 1.

Mar 27, 2025 · The battery pack voltage of lithium iron phosphate battery packs ranges from 275 to 401.5 V. Considering the safety during the experiments, a 315–361.5 V battery pack voltage

Pre-detection of thermal runaway in Li-ion 18650 batteries

Jun 15, 2025 · This study establishes a phenomenological method for detecting and categorising the stages of thermal runaway in 18650 lithium-ion batteries. Using surface temperature and

Systematic Characterization of Lithium-Ion Cells

Aug 16, 2025 · Accurate parametric modeling of lithium-ion batteries is essential for battery management system (BMS) design in electric vehicles and broader

Thermal runaway evolution of a 4S4P lithium-ion battery pack

Nov 1, 2024 · To clarify the thermal runaway characteristics of lithium-ion battery pack, this study has established a thermal runaway experimental platform based on actual power battery pack.

6 FAQs about [Lithium battery pack voltage and temperature collection]

What are the thermal requirements of battery packs?

The thermal requirements of battery packs are specific. Not only the temperatures of the battery cells are important but also the uniformity of the temperature inside the battery cell and within the battery pack are key factors of consideration, in order to deliver a robust and reliable thermal solution.

Can a lithium-ion battery estimate temperature?

Experimental validation of the estimation algorithm. Performance and safety of lithium-ion batteries depend on the ability to efficiently estimate their temperature during charge/discharge operations. We propose a novel algorithm to infer temperature in cylindrical lithium-ion battery cells from measurements of current and terminal voltage.

Can a lithium-ion battery model predict operating temperature in electric vehicles?

This model not only provides precise predictions for the operating temperature of lithium-ion batteries in electric vehicles but also offers valuable insights for optimizing thermal management strategies, which are crucial for improving the safety, performance, and lifespan of battery systems in real-world applications. 1. Introduction

How to evaluate the thermal management system of a Li-ion battery pack?

To evaluate the thermal management system of a li-ion battery pack, the design of experiments (DOE) has to incorporate a range of conditions to ensure that all thermal requirements are met: fast charging, cold start, charging at low temperature, discharging when the charge was low and different drive cycles .

What are lithium-ion battery packs?

Lithium-ion battery packs (LIBPs) play a crucial role in electrified transportation systems. The cost of LIBPs has a substantial impact on the manufacturing expenses of electric vehicles (EVs), typically representing 25% of the total EV production cost 1, and 75% of the powertrain cost 2.

Can a Kalman filter predict lithium-ion battery temperature?

We propose a novel algorithm to infer temperature in cylindrical lithium-ion battery cells from measurements of current and terminal voltage. Our approach employs a dual ensemble Kalman filter, which incorporates the enhanced single-particle dynamics to relate terminal voltage to battery temperature and Li-ion concentration.

Learn More

- Lithium battery pack voltage type

- 24V lithium battery pack voltage

- Lithium battery pack medium and high voltage box

- What is the use of high voltage lithium battery pack

- Lithium battery pack voltage container

- Lithium battery pack fast charging voltage

- Lima lithium battery pack temperature protection point

- Voltage of each battery in the lithium battery pack

- Masai electric storage vehicle lithium battery pack

Industrial & Commercial Energy Storage Market Growth

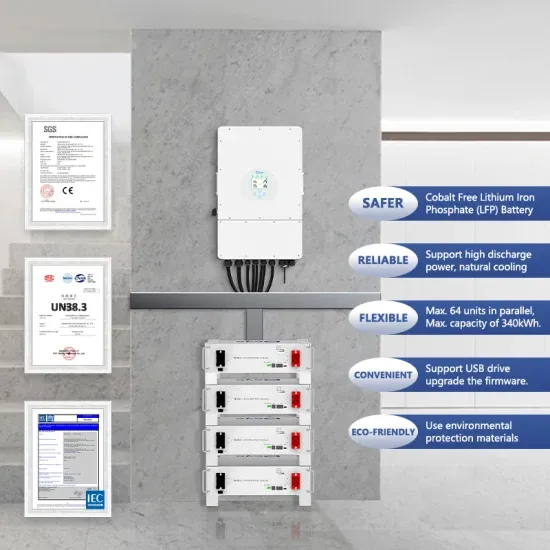

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.