Lithium Battery Pack Protection and Control

Aug 12, 2025 · TTapeTM device detects the temperature of each battery cell and connects to battery protection IC. When a cell''s temperature exceeds limits, TTapeTM resistance change

Investigation on enhancing thermal performance of the Li-ion battery

Jan 15, 2025 · The BTMS with alternated flow directions significantly improves the uniformity of temperature distribution in the battery pack. Specifically, the BTMS #C-in-C4 with engine oil

Lima lithium battery pack temperature protection point

Use special lithium battery protection chip, when the battery voltage reaches the upper limit or lower limit, the control switch device MOS tube cut off the charging circuit or discharging

Lithium Battery Pack Protection and Control

Market trends and drivers Safety and ageing concerns in Lithium battery applications highlight the critical need for advanced protection and control solutions in the market. Adoption of electric

Lithium-ion battery pack thermal management under high

Mar 1, 2024 · The stable operation of lithium-ion battery pack with suitable temperature peak and uniformity during high discharge rate and long operating cycles at high ambient temperature is

Low-Temperature Performance Best Practices for Lithium Batteries

Jul 25, 2025 · This guide provides a comprehensive, standards-backed checklist to maximize lithium battery safety, lifetime, and cost-effectiveness in climates as low as -20°C, drawing on

Thermal state monitoring of lithium-ion batteries: Progress,

Jan 1, 2024 · Transportation electrification is a promising solution to meet the ever-rising energy demand and realize sustainable development. Lithium-ion batterie

Lithium Ion Battery Packaging: Soft Pack Design

Apr 8, 2025 · Soft-pack lithium-ion batteries have become a popular power source for electronics, electric vehicles, and energy storage systems. Thanks to their

An experimental study on lithium-ion electric vehicles battery packs

Nov 1, 2024 · Key performance indicators used to assess battery thermal management system effectiveness include temperature uniformity, cooling effectiveness, energy usage, and effect

Comprehensive Guide to Lithium Battery Temperature

12 hours ago · Effective lithium battery temperature management protects your battery packs from dangerous failures and costly downtime. Poor temperature management can trigger thermal

Internal thermal network model-based inner temperature

Feb 1, 2020 · The lithium-ion battery pack is manufactured that many cells are connected in parallel or series to suit the purpose of use. Thus, the characteristics of the cells determine the

How Do BMS Protect Lithium Batteries? BMS for Battery Health

Sep 24, 2024 · Battery Management Systems (BMS) protect lithium batteries by monitoring their health and implementing safety protocols such as overcharge protection, temperature

In-situ temperature monitoring of a lithium-ion battery

Oct 1, 2022 · Uncertainty in the measurement of key battery internal states, such as temperature, impacts our understanding of battery performance, degradation and

6 FAQs about [Lima lithium battery pack temperature protection point]

Why do we need a cooling system for lithium-ion battery pack?

The stable operation of lithium-ion battery pack with suitable temperature peak and uniformity during high discharge rate and long operating cycles at high ambient temperature is a challenging and burning issue, and the new integrated cooling system with PCM and liquid cooling needs to be developed urgently.

Do lithium-ion batteries need protection circuits?

However, the need for protection circuits to maintain the voltage and current within safe limits is one of the primary limitations of the lithium-ion battery.

How to ensure stable operation of lithium-ion battery under high ambient temperature?

To ensure the stable operation of lithium-ion battery under high ambient temperature with high discharge rate and long operating cycles, the phase change material (PCM) cooling with advantage in latent heat absorption and liquid cooling with advantage in heat removal are utilized and coupling optimized in this work.

How to manage heat in lithium-ion batteries?

While cooling techniques offer a solution to overheating, another aspect we need to contemplate in managing heat in lithium-ion batteries is heat dissipation, especially in high-performance batteries. Heat dissipation is the process by which heat is directed away from the battery, preventing it from reaching dangerous temperatures.

What is lithium-ion heat management?

Lithium-ion heat management isn’t rocket science, but it does require a meticulous approach. We need to understand the battery’s operating conditions, its environment, and how it’s being used. Only then can we design appropriate heat management solutions. In essence, heat management in lithium-ion batteries is about safety and performance.

Are lithium ion batteries heat resistant?

Some brands have developed heat-resistant lithium-ion batteries, particularly designed to withstand high temperatures. Panasonic, for instance, has a line of lithium batteries touted for their heat resistance. They’re built with durable materials that can withstand higher temperatures without compromising performance.

Learn More

- Lithium battery pack protection module

- High voltage lithium battery pack protection solution

- Lithium battery pack voltage and temperature collection

- ASEAN lithium battery pack manufacturers

- Kitjia energy storage low temperature lithium battery

- Lithium battery pack serial charging

- Lithium battery pack medium and high voltage box

- Seeking the life of solar lithium battery pack

- Pakistan Karachi large single lithium battery pack

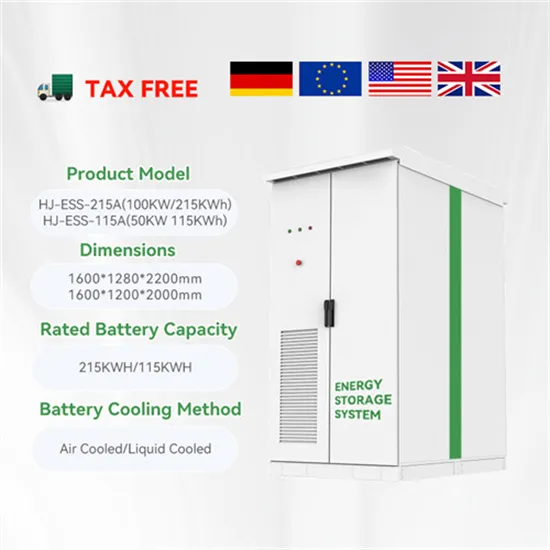

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.