How to Connect Lithium Batteries in Series and Parallel?

Aug 28, 2024 · Knowing how to connect these batteries in series, parallel, or even a combination, can help you tailor their performance to meet specific needs. In this article, we''ll explore the

How To Lookup Battery Serial Number?

May 26, 2025 · Battery serial numbers are unique alphanumeric codes assigned by manufacturers to identify production batches, warranty status, and technical specs. They''re

Optimal fast charging strategy for series-parallel configured lithium

Jan 1, 2025 · Leveraging the derived battery pack model, we introduce a refined online fast charging framework that mitigates lithium deposition. Fig. 3 outlines the architecture and

Helpful Guide to Lithium Batteries in Parallel and

Apr 23, 2024 · Lithium battery series and parallel: There are both parallel and series combinations in the middle of the lithium battery pack, which increases

Definition of Series and Parallel Connection of

Oct 26, 2021 · In parallel charging of lithium batteries, each lithium ion battery needs equalizing charge, otherwise, the performance and life of the whole

Charging Li-ion batteries in parallel

Aug 26, 2014 · I wanted some opinion on my set up here, just to make sure I got the basics right. I have a Li-ion battery charging circuit based on the MCP73113. This is designed to be a single

How To Wire Lithium Batteries In Series Increase Voltage

Mar 23, 2021 · To Series, Parallel, or Series and Parallel lithium batteries with a BMS you must first understand what a "true" BMS is, what it does, and what challenges the BMS in your

OPERATOR''S MANUAL 18 V LITHIUM-ION BATTERY PA

Aug 30, 2017 · 18 V LITHIUM-ION BATTERY PACK R840089 Use this battery pack for RIDGID® 18V cordless products only. Refer to the Operator''s Manual provided with product. Always

Unlock Maximum Power: Master Battery Configurations!

Choosing the right configuration for lithium-ion battery cells is crucial for achieving optimal performance, safety, and longevity in your battery pack. This comprehensive guide will explore

Serial and parallel switching and charging method and charging

The present invention is integrated into serial connection charge and charged in parallel in the monomer charging device, at monitoring circuit, under the control of control circuit and

How to Charge a Lithium-Ion Battery Properly: Step-by-Step

Nov 15, 2024 · Learn how to charge a lithium-ion battery safely and effectively with our guide to best practices, tips, and charging do''s and don''ts.

Charging Analysis for Lithium-Ion Battery Packs | SpringerLink

Jan 1, 2023 · In the battery pack, all cells share the same external charging/discharging current due to their serial connection. Since overcharging/overdischarging can shorten the battery

Best Practices for Charging Lithium Ion Batteries

Oct 20, 2024 · This guide provides you with a clear and authoritative set of best practices for charging series lithium-ion batteries. By following these

Optimal Lithium Battery Charging: A Definitive

Mar 12, 2024 · Unlock the secrets of charging lithium battery packs correctly for optimal performance and longevity. Expert tips and techniques revealed in our

Charging lithium-ion cells in series individually with multiple CC

May 11, 2020 · I''m looking to build a battery pack from lithium-ion 18650 cells, 13s16p (parallel first) to achieve around a 50V (nominal) battery pack. I realize there are probably charge

Service Manual (180 x 90 mm) Final

May 16, 2025 · About Shizen Energy India is a top lithium battery pack manufacturer, known for high-performance, advanced energy storage solutions.Our commitment to innovation and

Lithium Series, Parallel and Series and Parallel

Mar 23, 2021 · How to charge lithium batteries in parallel 4.1 Resistance is the enemy 4.2 How to charge lithium batteries in parallel from bad to best How to connect lithium batteries in series

6 FAQs about [Lithium battery pack serial charging]

How do you charge a lithium ion battery pack?

When charging a battery pack made up of several lithium-ion cells in series, always use a charger designed for the combined voltage. For example, if you have three 4.2-volt cells in series, you’ll need a charger that offers 12.6 volts. Using the wrong charger can damage your cells.

How to wire lithium batteries in series?

Lithium batteries are part of our everyday gadgets like phones, laptops, and even electric cars, so knowing how to wire them in series is essential for any practical project. To wire lithium batteries in series to increase voltage, connect the positive terminal of one battery to the negative terminal of the next.

Why are lithium batteries connected in series?

Lithium batteries are connected in series when the goal is to increase the nominal voltage rating of one individual lithium battery - by connecting it in series strings with at least one more of the same type and specification - to meet the nominal operating voltage of the system the batteries are being installed to support.

When should a lithium battery be connected in series?

You should connect lithium batteries in series when your device requires a higher voltage than a single battery can provide. For example, if your device operates at 7.4V, connecting two 3.7V batteries in series would be appropriate. This setup is commonly used in applications like electric scooters, drones, or other high-voltage devices.

Can a lithium ion battery be stacked in series?

At some point, the 3.6 V of a single lithium ion battery just won’t do, and you’ll absolutely want to stack LiIon cells in series. When you need high power, you’ve either got to increase voltage or current, and currents above say 10 A require significantly beefed up components.

How many cells are in a lithium-ion battery pack?

The method undergoes a real-world electric vehicle testing with 276 cells. The limited charging performance of lithium-ion battery (LIB) packs has hindered the widespread adoption of electric vehicles (EVs), due to the complex arrangement of numerous cells in parallel or series within the packs.

Learn More

- Lithium battery pack charging separately

- Lithium battery pack charging and discharging balancing machine

- Lithium battery pack charging times

- Lithium battery pack fast charging voltage

- Lithium battery pack split charging

- Charging management of lithium battery pack

- Maximum charging power of lithium battery pack

- European Union lithium battery pack series charging

- 60v lithium iron phosphate battery pack charging current

Industrial & Commercial Energy Storage Market Growth

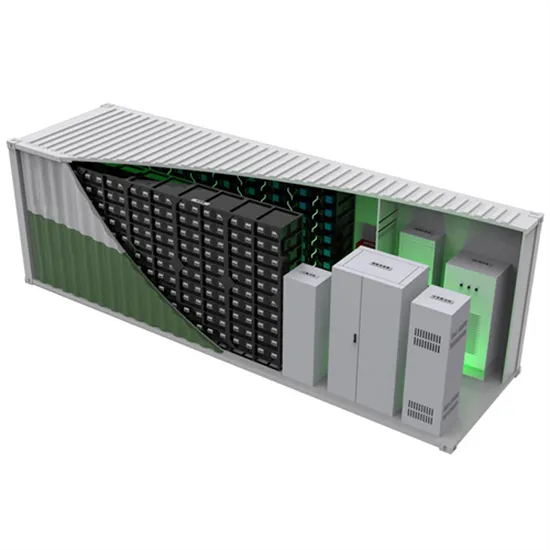

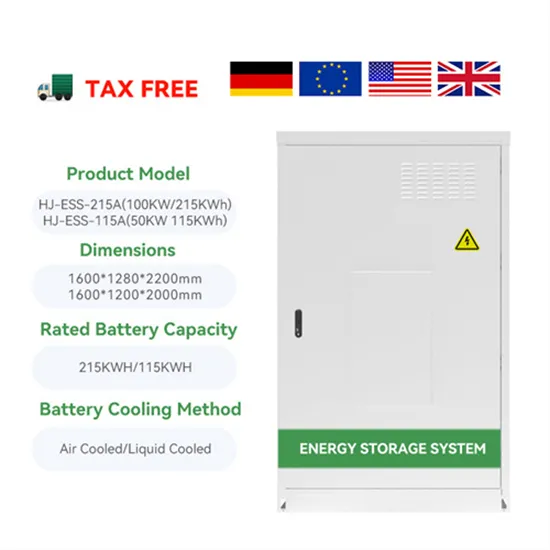

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

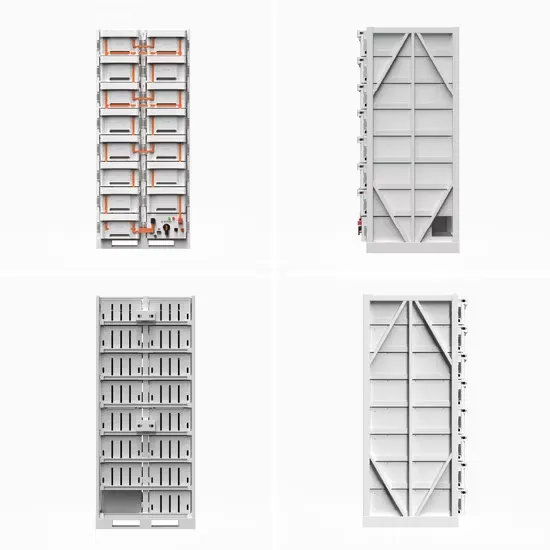

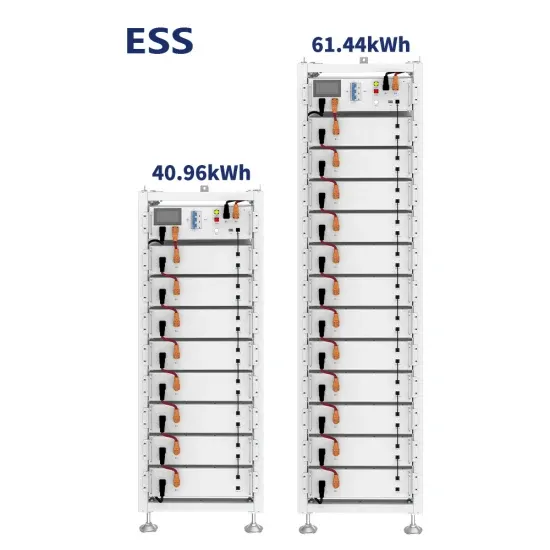

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.