Optimal Lithium Battery Charging: A Definitive

Mar 12, 2024 · Unlock the secrets of charging lithium battery packs correctly for optimal performance and longevity. Expert tips and techniques revealed in our

Battery Tester Manufacturer, Charge Station, Battery Charging

Lithium Battery Testing and Maintenance Video 5V 50A Lithium Battery Cell Capacity Grading Electric Car Traction Lithium Battery Pack Balance Maintenance Auto Cycle Charge and

A multi-agent reinforcement learning approach for continuous battery

Jun 1, 2025 · Cell balancing in lithium-ion battery packs is essential for optimal performance, with active balancing offering advantages over passive balancing but requiring complex

Battery Charging, Analyzing, and Balancing Solutions | ATEQ

2 days ago · Ideal for rework stations on EV vehicle production lines, the EVB 5100 Battery Module Balancing Machine uses the most efficient technologies to check state of charge and

Programmable logic controlled lithium-ion battery

Jun 1, 2024 · In this study, a Programmable Logic Controller (PLC) - based BMS proposal for lithium-ion batteries has been presented, aiming to address the challenges in existing BMSs.

Active Cell Balancing in Battery Packs

Nov 23, 2016 · In these situations, weaker cells are overstressed during charging, causing them to become even weaker, until they eventually fail and cause a premature failure of the whole

Li-Ion Cells: Charging and Discharging Explained

Jun 12, 2024 · It''s crucial to know how to charge and discharge li-ion cells. This article will provide you with a guide on the principles, currents, voltages, and

Lithium Battery Simple Balance Machine,Equilibrium Machine

Jun 26, 2025 · This is a simple balance machine for lithium battery with battery type of Ni-mh,Ni-cd, LiFepo4 LiNCM and LiNCA, operation current @ 0.5A - 5A. CD-P12-05 is suitable for the

Active cell equalization for lithium-ion battery packs in

Jul 1, 2025 · In Electric Vehicles (EVs), the battery pack is composed of hundreds or even thousands of Lithium-ion (Li-ion) cells connected in series to deliver the required power and

Battery Charge and Discharge Integrated Machine

The lithium battery charge-discharge integrated machine is equipped with multiple testing and maintenance modes, suitable for discharging, charging, cycle charge-discharge testing, and

Advanced pulse charging strategies enhancing performances of lithium

May 1, 2025 · The widely adopted constant current-constant voltage (CC-CV) charging protocol often results in polarization and lithium plating during high-speed charging, which poses

EP401 | Battery Charge & Discharge Equipment | SmartSafe

The EP401 is a battery pack module integrated charge-discharge machine designed based on the characteristics of lithium-ion batteries used in electrical vehicles. It can efficiently perform the

6 FAQs about [Lithium battery pack charging and discharging balancing machine]

Who makes lithium battery pack balance maintenance instrument?

Produced by Semco Infratech Pvt Ltd. Lithium battery pack balance maintenance instrument is a maintenance equipment for lithium battery packs of new energy vehicles.

What is EVB 5100 battery module balancing machine?

Ideal for rework stations on EV vehicle production lines, the EVB 5100 Battery Module Balancing Machine uses the most efficient technologies to check state of charge and equalize voltage differences between modules. Automatic 12v/50a, charge and quick diagnostic, for 12v lead, li-ion, li-po, ni-cd, ni-mh batteries.

How does the evb5100 module balancer work?

The EVB5100 Module Balancer charges or discharges the new replacement module to the same state of charge as the other modules. The EEST-75-40 charges and discharges complex batteries and provides detailed analytics monitoring each battery cell.

What is portable battery pack and charge intelligent?

Portable battery pack and charge intelligent the maintenance instrument is to solve the problem after the power battery is connected in series, due to each individual battery Developed to solve the problem of shortening the cycle life of battery packs caused by unbalanced expansion. Yes!

What is smartsafe eb480 lithium battery balancer?

SmartSafe EB480 Lithium battery balancer with 48-channel, high precision voltage sampling and accurate charge and discharge voltage & current control.

What is a battery charger analyzer (BCA)?

The BCA is a Battery Charger Analyzer designed to Charge, Discharge and Analyze all types of battery chemistry. It is housed in a metal enclosure with a 7 inch touchscreen control display. All settings and data can be entered via the touchscreen.

Learn More

- Lithium battery pack 1000V high voltage charging and discharging

- Charging management of lithium battery pack

- 60v lithium iron phosphate battery pack charging current

- Lithium battery pack serial charging

- Lithium battery pack fast charging voltage

- Lithium battery pack bulk charging equipment

- 36v12ah lithium iron phosphate battery pack

- 60V 50A lithium battery pack

- Assemble 15a lithium battery pack

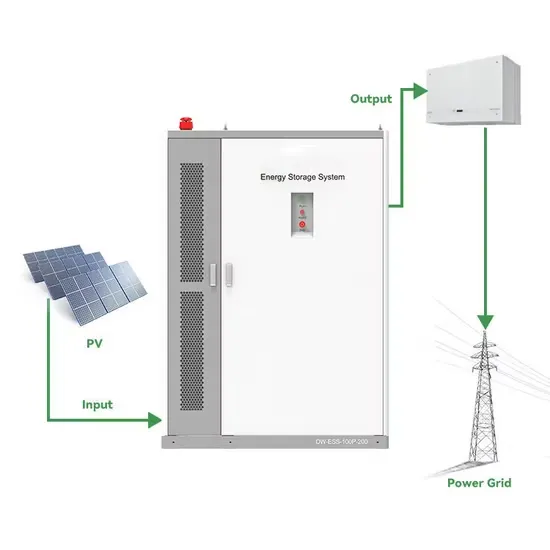

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

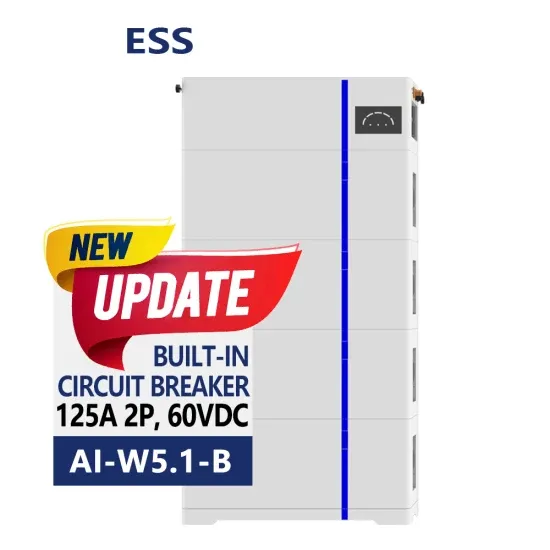

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.