How to Assemble a LiFePO4 Lithium Battery Pack for Solar

Jul 25, 2025 · As clean energy continues to rise in popularity, lithium-ion batteries—especially LiFePO4 (Lithium Iron Phosphate)—are essential in everything from solar home kits to

ElectroGlobal 3S 15A Lithium Battery Protection BMS

It also comes with a nickel strip, which is necessary to assemble and connect the battery pack securely. The module integrates crucial protective functions, such as preventing overcharging,

How to Assemble an Electric Bike Battery Pack – BATTERYINT

To ensure the normal operation of a 1000W motor, the required current is 20.8A. You need to select 21700 5Ah 3C cells and configurea battery pack with 13 series and 2 parallels. Because

Beginner-Friendly Tips for Assembling Lithium Battery Packs

May 7, 2025 · Learn how to assemble a lithium battery pack with beginner-friendly tips on design, safety, and tools for optimal performance and reliability.

Custom Batteries, Battery Packs, OEM Pack Assemblies

Sample of our UN38.3 tested batteries. Help to apply IEC62133 for battery packs build by battery space. Sample of Custom Nimh battery packs, Custom Lithium Ion 18650 battery packs,

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · In order to deliver the required power and energy as per the application, it is necessary to assemble the individual Li-ion cells in series and parallel configuration to make

How to Build a Lithium Ion Battery Pack? A Step by Step

Apr 9, 2025 · Starting from selecting materials and tools needed in how to build a lithium ion battery pack, designing the battery pack, step by step in how to build a lithium ion battery

How to Make a 24V Battery Pack

Apr 10, 2025 · Creating a 24V battery pack involves connecting two 12V batteries in series or assembling individual lithium cells to achieve the desired voltage and capacity. Have you ever

How to Build a Lithium Battery: Step-by-Step for Beginners

Feb 22, 2024 · How to build a lithium battery pack? 1. Prepare materials and tools. The following materials and tools are required to assemble the lithium battery pack. a. Lithium battery cell:

BATTERY MODULE AND PACK ASSEMBLY PROCESS

The battery production department focuses on battery production technology. Member companies supply machines, plants, machine components, tools and services in the entire process chain

Electroglobal 3S 15A Lithium Battery Protection BMS Module

Buy Electroglobal 3S 15A Lithium Battery Protection BMS Module with Nickel Strip Single-Sided PCB for Rs. online. Electroglobal 3S 15A Lithium Battery Protection BMS Module with Nickel

How to Build a Lithium Ion Battery Pack: Expert Guide for

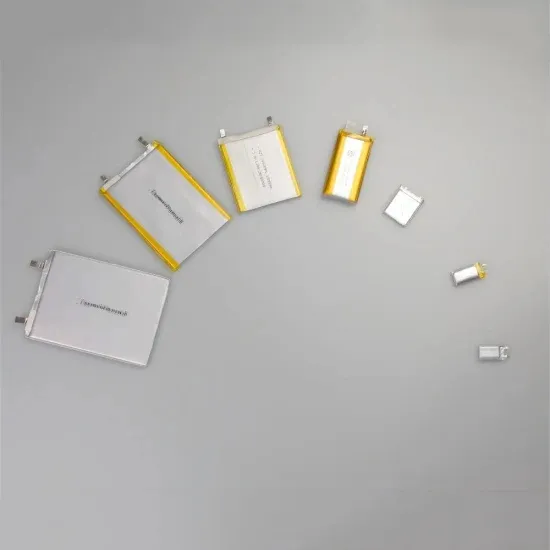

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

How to Assemble a Battery Pack in 8 Easy Steps? [2025 Guide]

Jun 15, 2025 · In this step-by-step guide, as a professional lithium battery pack manufacturer, I''ll walk you through the entire DIY battery pack assembly process to help you build a safe, high

How to Assemble Lithium Battery Cells into Battery Pack

Apr 14, 2025 · The process of assembling lithium battery cells into complete battery pack is called battery PACK. It involves integrating key components such as battery cells, protection board,

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · In this guide, we''ll walk you through everything you need to know – from the basics of what a battery pack is, to the tools and materials required, the step-by-step assembly

6 FAQs about [Assemble 15a lithium battery pack]

How to build a lithium battery?

Part 4. Conclusion Building a lithium battery involves several key steps. First, gather the necessary materials, including lithium cells, a battery management system, connectors, and protective casing. Begin by designing the battery layout, ensuring proper spacing and alignment of cells.

Why is quality control important in a lithium battery pack assembly?

Consequently, this intricate step paves the way for efficient power transfer and optimal pack performance. Quality control is a cornerstone of the lithium battery pack assembly process.

How do you test a lithium battery pack?

Voltage and Current Testing: Use a multimeter to ensure the pack operates within safe parameters. Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations.

What is a high-performance lithium battery pack?

As the world transitions towards sustainable energy solutions, the demand for high-performance lithium battery packs continues to soar. At the heart of this burgeoning industry lies a meticulously orchestrated assembly process, where individual lithium-ion cells are transformed into powerful energy storage systems.

What is a lithium primary battery?

A lithium primary battery (Lithium Primary Battery) is a non-rechargeable battery that uses lithium metal or lithium compounds as the negative electrode material. Unlike rechargeable lithium-ion batteries, this type of battery is mainly used for one... High safety and long life!

How to connect a lithium battery cell to a protective circuit board?

Use tape or other fixing methods to secure the protective circuit board to the lithium battery cell. This prevents it from loosening or shifting. Make sure there is no metal contact between the protective circuit board and the lithium battery cell to avoid short circuit or other safety issues. 5. Connect the wires

Learn More

- Assemble 48V 12Ah Lithium Battery Pack

- Pakistan Karachi large single lithium battery pack

- 12ah lithium battery pack

- ASEAN lithium battery pack manufacturers

- Islamabad 12v lithium battery pack

- 72v70A lithium battery pack

- Class 9 lithium battery pack identification

- Uganda lithium battery pack 72v assembly

- Lithium battery pack 1000V high voltage charging and discharging

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.