Lithium-ion Battery 48V Lithium Battery Pack 12000mAh

Feb 4, 2025 · Amazon : FREEDOH Lithium-ion Battery 48V Lithium Battery Pack 12000mAh Replacement Battery 12AH for 0-600W Motor with Charger and BMS Protection Board :

48v lithium battery pack assembly

1. Before assembling a 48V lithium battery pack, it is necessary to calculate the size of the product and the required load capacity, etc., then, according to the capacity of the product, and

How to assemble a 12v48 lithium battery pack

How to assemble a 48v battery pack? Once you have the required number of cells, it''s time to assemble your 48v battery pack. Follow these steps for a successful assembly: Gather the

An Extremely Detailed 48V Lithium ion Battery Assembly

Mar 28, 2025 · Building a 48V battery pack involves several crucial steps, from selecting the right cells to assembling and testing the pack. Below is a step-by-step guide to walk you through

INSTRUCTION MANUAL: BATTERY PACK DESIGN, BUILD

Apr 29, 2021 · install partitions between BMS and cells check if the pack is designed to be able to avoid thermal runaway analyze the battery pack''s thermal distribution and its effect on the

48V 12AH Lithium Ion Battery Pack for Electric mobility

Oct 30, 2022 · 48V 12AH Lithium Ion Battery Pack for Electric mobility scooters from Chinese Electrical Equipment & Supplies supplier - Meo wig Trading Co., Ltd on tradechina

DIY 48V Battery Pack: Essential Tips, Materials, and Building

Apr 16, 2025 · To properly assemble a 48V battery pack, gather the necessary materials, follow a specific arrangement of cells, make secure connections, and test the final product for

A super detailed 48V lithium battery assembly tutorial

Oct 29, 2021 · 48V lithium iron phosphate battery assembly detailed tutorial. 1, choose the right cell, cell type, voltage, internal resistance needs to match, before assembly, please do a good

Battery Pack Calculator | Good Calculators

Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and maximum discharge

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · Conclusion Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations. By following this

How to Make a 48V Lithium-Ion Battery

Aug 19, 2025 · Follow the step-by-step instructions to assemble the battery cells, connect the cells in series to achieve the desired voltage, and ensure proper insulation and heat dissipation.

How to assemble a 12v lithium phosphate battery pack

MAENT® 12V 12ah LifePO4 Lithium Iron Phosphate Battery LFP Battery Battery: LifePO4 12.8v Battery pack Capacity: As per selection Battery Type: Rechargeable LifePO4 battery.

Lithium-ion battery pack for electric bike

The Ultramax 48V 12Ah Lithium Battery is supplied fully protected by a sophisticated specially designed lithium battery management system that constantly monitors every cell to ensure the

48V 12Ah Ebike Battery 36V 48V 52V 12Ah 20Ah 30Ah

Nov 20, 2024 · 48V 12Ah Ebike Battery 36V 48V 52V 12Ah 20Ah 30Ah Electric Bike Scooter Lithium Ion Battery with 54.6V 2A Charger and 30AMP BMS for 200W-800W Electric Bicycle

48V 12AH (15S2P) LIFEPO4 RECHARGEABLE BATTERY

Mar 18, 2024 · The 48V 12Ah (15S2P) LiFePO4 battery is a strong and dependable alternative for a variety of applications requiring long life, safety, and good power delivery.

6 FAQs about [Assemble 48V 12Ah Lithium Battery Pack]

How do I build a 48v battery pack?

Building a 48V battery pack involves several crucial steps, from selecting the right cells to assembling and testing the pack. Below is a step-by-step guide to walk you through the entire process. The first step is to choose the appropriate battery cells.

How many cells do I need for a 48v battery pack?

For a 48V battery pack, you will typically need 13 cells arranged in series if you’re using 3.7V lithium-ion cells. This configuration will give you the desired voltage (3.7V x 13 = 48.1V). Make sure to pick high-quality cells that are rated for the specific application, whether for energy storage, electric vehicles, or off-grid systems.

What voltage should a 48v battery pack read?

A healthy 48V battery pack should read between 48V and 50V when fully charged. If any of the cells are undercharged or overcharged, recalibrate your system by balancing the cells. Building a 48V battery pack is an exciting project, but it comes with its own set of challenges.

What is a 48V 100A BMS battery?

The BMS Battery 48V 100A BMS is specifically designed for 48V lithium-ion battery packs. This Battery Management System (BMS) ensures that each cell in the pack is balanced, prevents overcharging, and adds an extra layer of protection to your pack.

How often should a lithium ion battery be charged?

Lithium-ion batteries, in particular, should not be discharged to 0% frequently, as this can reduce the battery’s lifespan. Aim to keep your battery pack’s charge level between 20-80% for optimal performance. Tip: Use your battery pack within its recommended voltage range to avoid damaging the cells.

Can I use same cells in the same battery pack?

A: No, it's strongly recommended to use identical cells in the same battery pack. You should always use cells from the same manufacturer, with the same specifications and date code.

Learn More

- 48v 10a lithium iron phosphate battery pack

- Mali 48v power tool lithium battery pack

- 72v lithium battery pack frequently loses power

- Lithium battery pack series discharge

- Middle East 72v lithium battery pack manufacturers

- Bishkek Pack Lithium Battery Company

- Bissau lithium battery pack price

- Light truck lithium iron phosphate battery pack

- Cote d Ivoire BESS lithium battery pack

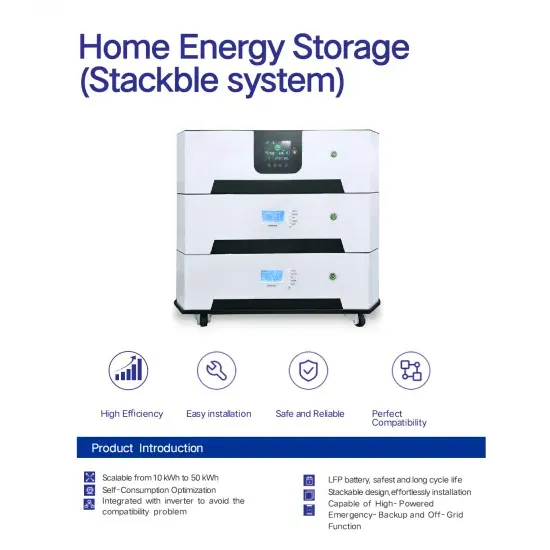

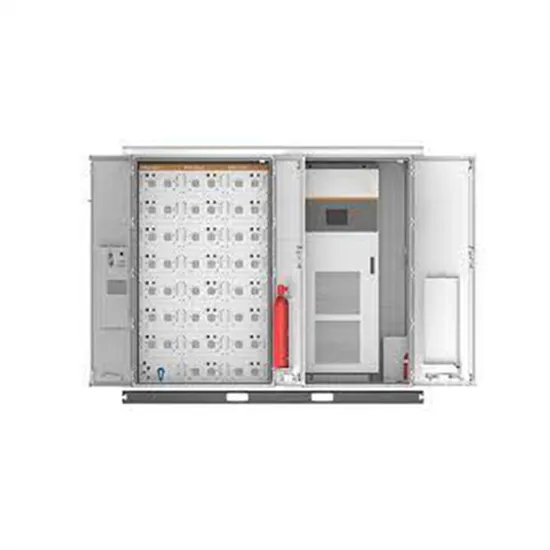

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.