A Guide to Understanding Battery Specifications

Dec 18, 2008 · Battery Basics Cell, modules, and packs – Hybrid and electric vehicles have a high voltage battery pack that consists of individual modules and cells organized in series and

The Handbook of Lithium-Ion

Aug 16, 2025 · The Handbook of Lithium-Ion Battery Pack Design This page intentionally left blank The Handbook of Lithium-Ion Battery Pack Design Chemistry, Components, Types and

Battery pack calculator : Capacity, C-rating, ampere, charge

Free battery calculator! How to size your storage battery pack : calculation of Capacity, C-rating (or C-rate), ampere, and runtime for battery bank or storage system (lithium, Alkaline, LiPo, Li

Optimal Lithium Battery Charging: A Definitive

Mar 12, 2024 · Unlock the secrets of charging lithium battery packs correctly for optimal performance and longevity. Expert tips and techniques revealed in our

Exploring self-discharge characteristics of lithium-ion

Feb 28, 2025 · Exploring self-discharge characteristics of lithium-ion batteries corroded by salt spray condition Laiqiang Kong, Sidun Fang, Tao Niu, Guanhong Chen, Lijun Yang, Ruijin

FGCD Series Battery Discharge-Charge Unit (High-Voltage

FGCD series tester adopts advanced charging and discharging technology with a variety of built-in test and maintenance modes. It is suitable for discharging, charging, and cycle charge and

NPFC Series Product Manual 48NPFC100 Lithium Battery

Nov 4, 2024 · 2. Product Introduction 48NPFC100 lithium battery pack is an advanced product developed according to the requirements of new backup power supply for communication

Battery Pack Calculator | Good Calculators

Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and maximum discharge

What Are the Discharge Characteristics of Li-ion Batteries

Jul 22, 2025 · These characteristics describe how voltage drops during discharge, how a flat discharge curve supports stable power, and how current, temperature, and chemistry shape

6 FAQs about [Lithium battery pack series discharge]

What are the discharge characteristics of lithium ion batteries?

When you analyze the discharge characteristics of li-ion batteries, you focus on the charge-discharge curves. These curves show how voltage and current change as the battery charges and discharges. You typically see a flat discharge curve in lithium-ion cells, which means the voltage remains stable through most of the discharge cycle.

How long does it take to discharge a lithium ion battery pack?

The nominal voltage of each cell is 3.7 and thus the total voltage of the battery pack is vary between 11 to 12 volts. It takes 4000 seconds to discharge the lithium-ion battery pack completely to zero SOC. The below circuit shows the current and voltage of the battery pack.

How does discharge rate affect thermal performance of lithium-ion batteries?

Discharge rate showed the highest contribution followed by electrical configuration. Discharge rate impacts T max by 44 % and ΔT max by 58.2 %. Proposed optimum condition for thermal performance of LIB pack. Lithium-ion batteries are increasingly preferred for energy storage, particularly in Electric Vehicles (EVs).

What is a lithium ion battery discharging circuit?

This is a discharging circuit of the lithium-ion battery pack which consists of three lithium-ion cells, load resistance, MOSFET, relational operator, constant, display, current measurement, voltage measurement, etc. The three batteries or cells are connected in series with the load resistance.

Why do lithium ion batteries have a flat discharge curve?

These curves show how voltage and current change as the battery charges and discharges. You typically see a flat discharge curve in lithium-ion cells, which means the voltage remains stable through most of the discharge cycle. This stability is essential for battery pack reliability in industrial, medical, and robotics applications.

How do lithium ion batteries work?

Learn more about lithium-ion batteries. Li-ion batteries have a mostly flat discharge voltage curve, which helps devices run steadily until the battery is nearly empty. Discharge rate, temperature, and battery chemistry strongly affect battery capacity, lifespan, and safety; managing these factors improves performance.

Learn More

- Shallow charge and discharge of lithium battery pack

- Lomei square 17 series 60v lithium battery pack

- 8 4v lithium battery pack in series

- 12v30ah polymer lithium battery pack

- Which lithium battery pack in ASEAN is reliable

- Santo Domingo RV lithium battery pack

- 60v lithium iron phosphate battery pack charging current

- Czech household energy storage lithium battery pack

- ASEAN lithium battery pack manufacturers

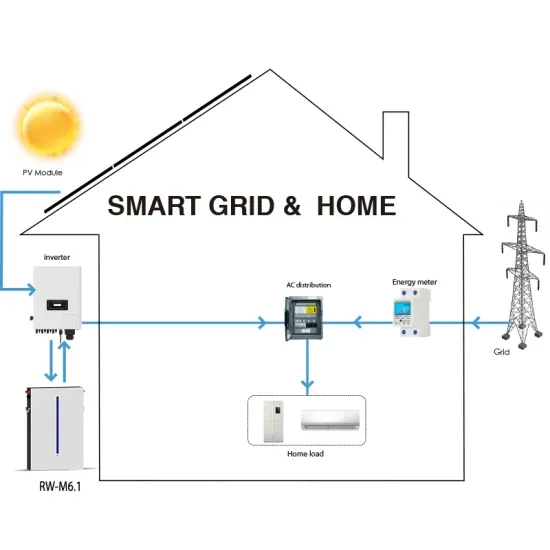

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.