In Stock 2 cell pack 8.4V Lithium Ion Battery

Mar 5, 2025 · 7.2V 7.4V li ion battery charger, 8.4V Universal AC input OEM and consumer lithium-ion battery charger for 2 cell packs, 8.4V charging voltage,

How to Connect Lithium Batteries in Series and

Jun 7, 2024 · In this article, we''ll explore the basics and provide detailed, step-by-step instructions on how to connect lithium batteries in series, parallel, and

Battery pack calculator : Capacity, C-rating, ampere, charge

Battery calculator : calculation of battery pack capacity, c-rate, run-time, charge and discharge current Onlin free battery calculator for any kind of battery : lithium, Alkaline, LiPo, Li-ION,

Introduction: What Is a Lithium-Ion Battery Pack?

Jul 4, 2025 · Lithium-ion battery packs are essential power sources used in medical equipment, drones, robots, and countless other devices. These packs are made of multiple Li-ion cells

Buy Best Quality 2s lithium-ion battery with

5 days ago · Discover our range of 2 Cell (7.4V~8.4V) lithium-ion battery packs, designed to provide reliable and consistent power for your electronic devices

How to Correctly Connect Batteries in Series and

Apr 10, 2025 · Understanding how to properly connect batteries in series and parallel formula might seem straightforward, but by adhering to a few simple

Lithium Rechargeable Batteries – IBEX Resources

Take an example of a 7.4V 24.8Ah lithium battery pack (16 cells connected in 2 series, 8 parallel): To fully recharge the pack you need to put in up to 24.8Ah. Say you have a max charge time

Charging Circuit for 2S (8.4V) Battery Pack (2 x 18650 in series)

Oct 9, 2024 · Can''t go into much detail, but basically it''s a battery powered circuit that draws between 15mA in idle state, up to 2.5 A peak, at 5V DC. I have the choice of: - powering this

Ultimate Power: Lithium-Ion Batteries In Series

Apr 4, 2024 · At some point, the 3.6 V of a single lithium ion battery just won''t do, and you''ll absolutely want to stack LiIon cells in series. When you need high

Help in making an 8.4v, 4×18650 cell

Feb 19, 2013 · The standard battery pack is some sort of 4 x 18650 cell configuration but I can''t workout the set up to get the 8.4v it''s stated to be. Some sort of circuitry within the battery pack?

Battery Pack Calculator | Good Calculators

Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and maximum discharge

How to Correctly Connect Batteries in Series and

Apr 10, 2025 · For instance, a laptop battery may consist of four 3.6V lithium-ion cells connected in series, reaching a total voltage of 14.4V. Then, two sets of

18650 Battery Pack Kit (8.4V / 12.6V) with Storage Box

Designed to support both 8.4V (2S) and 12.6V (3S) outputs, this kit gives flexibility for use in LED lighting, power banks, e-bikes, routers, or small UPS systems.The sturdy black storage box is

Battery configurations (series and parallel) and

Jun 26, 2023 · The other lithium-based battery has a voltage between 3.0 V and 3.9 V. Li-phosphate is 3.2 V, Li-titanate is 2.4 V. Li-manganese, and other

Lithium Series, Parallel and Series and Parallel

Mar 23, 2021 · To Series, Parallel, or Series and Parallel lithium batteries with a BMS you must first understand what a "true" BMS is, what it does, and what challenges the BMS in your

Charging Multi-Cell Lithium-Ion Battery Packs

Mar 7, 2025 · With two cells in series and both being charged at 4.2V, the charge voltage must be 8.4V. Use a 12V or greater supply for this. To determine the input voltage, multiply the number

6 FAQs about [8 4v lithium battery pack in series]

What are the different types of lithium battery packs?

Lithium battery series and parallel: There are both parallel and series combinations in the middle of the battery pack, which increases the voltage and increases the capacity. Such as 4000mAh, 6000mAh, 8000mAh, 5Ah, 10Ah, 20Ah, 30Ah, 50Ah, 100Ah and so on. Take 48V 20Ah lithium battery pack as an example Lithium Battery PACK

What batteries are included in the battery library?

The library includes information on a number of batteries, including Samsung (ICR18650-30B, INR18650-25R), Sony (US18650GR, US18650VTC6), LG (LGABHG21865, LGDBMJ11865), Panasonic (UR18650NSX, NCR18650B), and many more. Max. Cell Voltage (V): Pack Max. Voltage: 0 Max.

What does 3.8v/cell mean on a lithium ion cell?

On a lithium-ion cell, 3.8V/cell indicates a state-of-charge of about 50%. It must be noted that utilizing voltage as a fuel gauge function is inaccurate because cells made by different manufacturers produce a slightly different voltage profile. This is due to the electrochemistry of the electrodes and electrolyte.

Why are lithium batteries connected in series?

Lithium batteries are connected in series when the goal is to increase the nominal voltage rating of one individual lithium battery - by connecting it in series strings with at least one more of the same type and specification - to meet the nominal operating voltage of the system the batteries are being installed to support.

How many volts does a battery pack produce?

Figure 2 shows a battery pack with four 3.6V Li-ion cells in series, also known as 4S, to produce 14.4V nominal. In comparison, a six-cell lead acid string with 2V/cell will generate 12V, and four alkaline with 1.5V/cell will give 6V. Adding cells in a string increases the voltage; the capacity remains the same.

What is the cell voltage of a lithium ion battery?

The nominal cell voltage for a nickel-based battery is 1.2V, alkaline is 1.5V; silver-oxide is 1.6V and lead acid is 2.0V. Primary lithium batteries range between 3.0V and 3.9V. Li-ion is 3.6V; Li-phosphate is 3.2V and Li-titanate is 2.4V. Li-manganese and other lithium-based systems often use cell voltages of 3.7V and higher.

Learn More

- 4V large capacity lithium battery pack accessories

- 6 lithium battery pack 7 4v

- Lomei square 17 series 60v lithium battery pack

- Pakistan 13 series lithium battery pack

- Lithium battery pack series discharge

- Imported lithium iron phosphate battery pack

- Peru ups power lithium battery pack

- Lithium battery pack 8s

- Mexican lithium battery pack

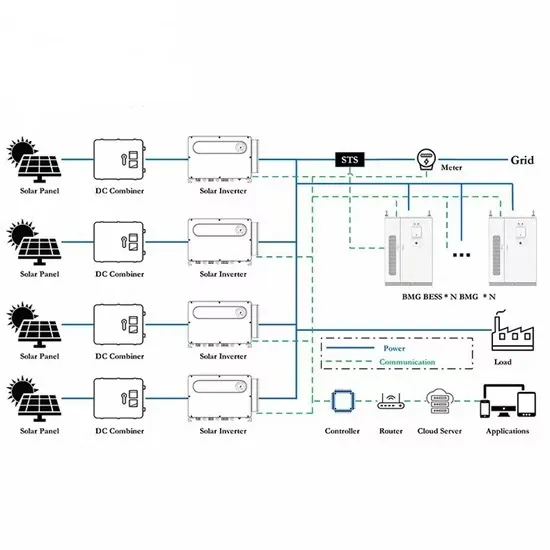

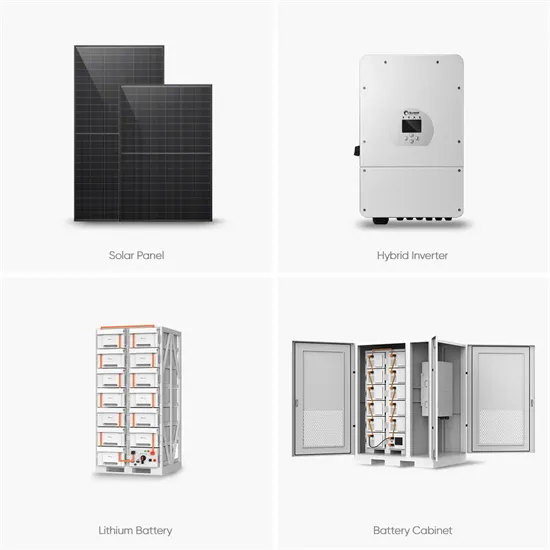

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.