Battery protectors

2 days ago · Get a short overview of system requirements to help you choose a battery protector, monitor or gauge. This reference design is a low standby and ship-mode current consumption

One Cell Lithium-ion/Polymer Battery Protection IC

Dec 25, 2019 · HM5455 contains advanced power MOSFET, high-accuracy voltage detection circuits and delay circuits. HM5455 is put into an ultra-small SOT23-5 package and only one

How High-Voltage BMS Enhance Safety and Battery

Mar 27, 2025 · By ensuring better battery-monitor accuracy and increasing system-level safety, the BMS helps maintain efficient energy usage and delays premature battery degradation,

Protection for Lithium-Ion Batteries | Lithium-Ion

Aug 5, 2025 · The overcharge, overdischarge, discharging overcurrent, charging overcurrent, and short protection of the rechargeable Lithium-ion or Lithium

High Voltage Lithium Battery Packs – Reliable Energy Solutions

Discover high voltage lithium battery packs designed for electric vehicles, renewable energy, and industrial applications. Our products offer exceptional energy density, safety, and longevity.

Lithium Battery Pack Protection and Control

Adoption of electric vehicles, both in the automotive and e-mobility sectors, is driving the demand for high-performance lithium battery solutions. Lithium batteries are widely used in energy

High-Volt Lithium Marine Battery System MBmax16.3H

Jul 8, 2025 · ROYPOW High-volt Lithium Marine Battery System with DNV Type Approval is designed to reduce fuel consumption, lower operational costs, and minimize carbon emissions

Battery Pack Cell Voltage Difference and

Jan 18, 2021 · If there is a BMS or other protection circuit measures, any cell voltage will reach the limit of undervoltage protection, and the protection circuit

Battery protectors

2 days ago · We understand performance and safety are major care-abouts for battery packs with lithium-based (li-ion and li-polymer) chemistries. That is why we design our battery protection

Battery protection selection guide

May 24, 2025 · For that, Infineon ofers a wide range of battery protection solutions that, under stressful conditions, increase lifetime and eficiency of lithium batteries. The battery protection

One Cell Lithium-ion/Polymer Battery Protection IC

Oct 27, 2017 · The HM5436D product is a high integration solution for lithium-ion/polymer battery protection. HM5436D contains advanced power MOSFET, high-accuracy voltage detection

Challenges in Li-ion battery high-voltage technology and

Apr 1, 2024 · This article presents an overview of these concerns to provide a clear explanation of the issues involved in the development of electrolytes for high-voltage lithium-ion batteries.

One Cell Lithium-ion/Polymer Battery Protection IC

Oct 11, 2024 · One Cell Lithium-ion/Polymer Battery Protection IC General Description The LN8231 provides a high integration solution for lithium-ion/polymer battery protection. The

One Cell Lithium-ion/Polymer Battery Protection IC

Oct 29, 2019 · The HM5491IS product is a high integration solution for lithium-ion/polymer battery protection. HM5491IS contains advanced power MOSFET, high-accuracy voltage detection

6 FAQs about [High voltage lithium battery pack protection solution]

What is lithium ion battery protection IC?

Lithium-Ion Battery protection IC using high voltage CMOS process for overcharge, overdischarge and overcurrent protection of the rechargeable Lithium-ion or Lithium-polymer battery.

How to detect a rechargeable lithium ion or lithium-polymer battery?

The overcharge, overdischarge, discharging overcurrent, charging overcurrent, and short protection of the rechargeable Lithium-ion or Lithium-polymer battery can be detected. Each of these IC composed of four voltage detectors, short detection circuit, reference voltage sources, oscillator, counter circuit and logical circuits.

What is ap9101c battery protection IC?

Li+ Battery Protection IC For Single Cell Pack AP9101C is a protection solution developed for lithium-ion and lithium- polymer rechargeable batteries with a high- precision voltage detection circuit.

What is Infineon battery protection?

For that, Infineon ofers a wide range of battery protection solutions that, under stressful conditions, increase lifetime and eficiency of lithium batteries. The battery protection circuit disconnects the battery from the load when a critical condition is observed, such as short circuit, undercharge, overcharge or overheating.

What is IUM ion/polymer battery protection?

ium-ion/polymer battery protection. +0 contains internalpower MOSFET, high-accuracy voltage detection circuits and delay circuits. +0 has all the protection functions required in the battery application including overcharging, over dischargi g, overcurrent and load short circuiting protection etc. The accurate overcharging dete

Why do you need a battery protection IC?

That is why we design our battery protection ICs to detect a variety of fault conditions including overvoltage, undervoltage, discharge overcurrent and short circuit in single-cell and multi-cell batteries, so you can enhance the safety of your battery pack.

Learn More

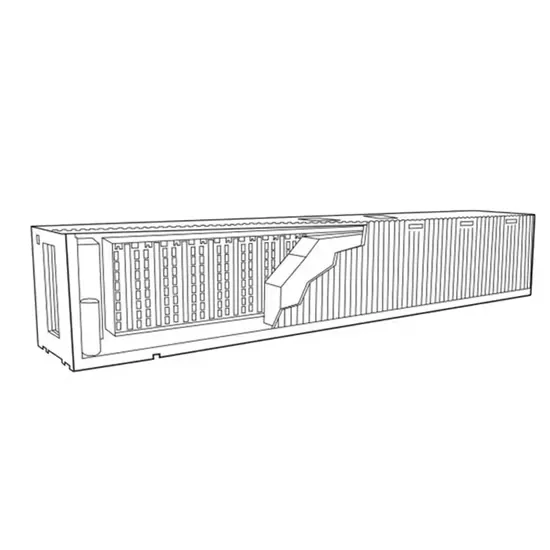

- Lithium battery pack 1000V high voltage charging and discharging

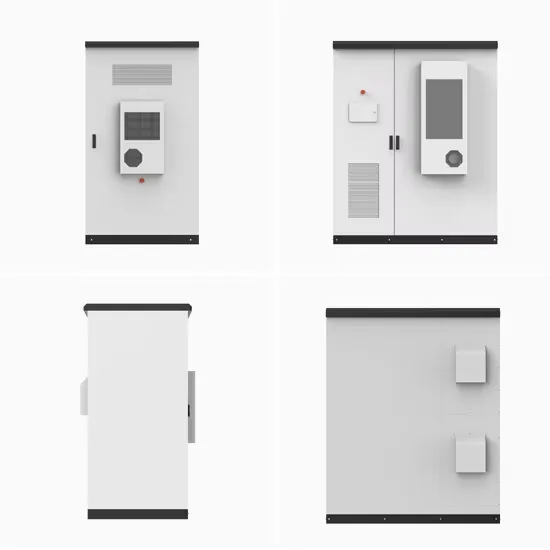

- Lithium battery pack medium and high voltage box

- What is the use of high voltage lithium battery pack

- Full-charge voltage of lithium battery pack

- Lithium battery high voltage energy storage system

- Lithium battery module pack full stack solution supplier

- Voltage of each battery in the lithium battery pack

- Does the lithium battery pack have reverse charge protection

- Minimum allowable voltage of lithium iron phosphate battery pack

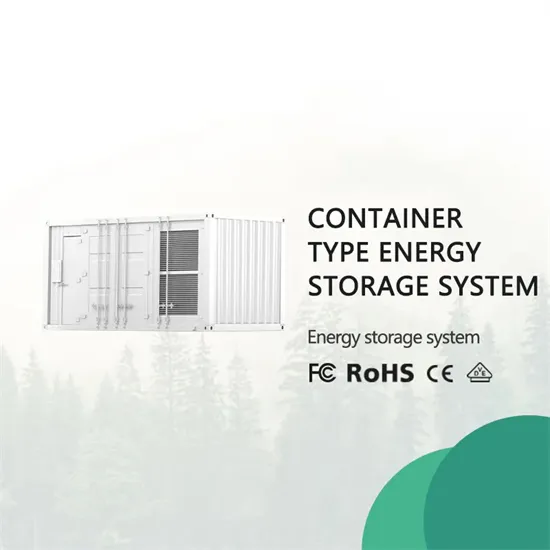

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.