Reverse Voltage Protection for Li-ion battery charging circuit

May 22, 2025 · It doesn''t follow a charge profile or terminate charge per recommendations, nor will it detect over-discharged cells and do recovery charging. The BMS may protect against

Do li ion battery chargers have reverse

Our Li Ion Battery Charger 54.6 V, 54.6V 5A Li - ion Smart Charger, and 54.6V 2A Charger are all designed to offer reliable reverse - polarity protection, ensuring the safety and longevity of your

How to Prevent Reverse Charging of a Lithium

Jan 31, 2014 · All Intersil''s RTCs with a Battery Switchover feature such as the ISL12026 series have internal protection circuit to prevent reverse charging.

Lithium, Safety Precautions

Oct 12, 2019 · Primary Batteries Since lithium primary batteries are not rechargeable, use a reverse current blocking diode and a protective resistor in series where there is the possibility

Battery protection selection guide

May 24, 2025 · Mishandling lithium batteries can lead to serious failures like thermal runaway, lithium plating, electrode decomposition, etc. Consequently, such batteries require special care

Understanding LiPo charging / protection circuit

Apr 9, 2017 · Protection circuits are usually distinct from charging circuits. Many battery packs are designed with the intention of being charged by a dedicated

The Basics of Charging Lithium Batteries | RELiON

Aug 26, 2024 · Whether you''re using lithium batteries as part of a portable power station, or to power your boat, golf car or RV, understanding the basics of

AN1535: Prevent Reverse Charging of a Lithium Battery

Oct 10, 2024 · Specifically, UL standard 60950-1 describes the guidelines for Lithium batteries. All Intersil''s RTCs with a Battery Switchover feature, such as the ISL12026 series, have internal

bq76200 Reverse Voltage Considerations

Apr 1, 2023 · In a battery system, polarity is important to provide the proper voltage to the system and keep currents within design limits. The PACK+ terminal of a battery will typically be

Six System Architectures With Robust Reverse Battery

Apr 1, 2023 · This application report highlights how the new LM74800-Q1 back-to-back power N-channel FET-based ideal diode controller with load dump protection simplifies the reverse

Reverse-Current Circuitry Protection | Analog Devices

Figure 5. This high-side PMOS FET switch offers simple reverse-current protection in exchange for higher on-resistance and cost. The Challenge of Low-Battery Voltages For battery voltages

BMS Protection Functions for Lithium Battery Pack

Sep 10, 2020 · Overvoltage Protection The voltage of a single cell in the battery pack exceeds the allowable voltage. According to the purpose of protection,

How to Understand and Prevent Reverse Polarity in Batteries

1 day ago · Key Takeaways Always check battery terminals carefully before connecting to avoid reverse polarity, which can cause overheating, damage, or fire. Use battery packs and

Battery protectors

2 days ago · We understand performance and safety are major care-abouts for battery packs with lithium-based (li-ion and li-polymer) chemistries. That is why we design our battery protection

The Essential Guide to Reverse Battery Protection

One essential aspect often overlooked is reverse battery protection—a fundamental mechanism that ensures longevity and safety in solar battery charging setups. This guide will walk you

Lithium Battery Protection Circuit

Dec 28, 2016 · I was studying a battery protection chip and reference circuit (below) commonly used in cell phone Li-ion batteries, and am confused by the two MOSFETs in series on the

Battery protection units (BPU) | Infineon Technologies

A battery protection unit (BPU) prevents possible damage to the battery cells and the failure of the battery, enhancing the useful operating life of lithium-ion batteries by protecting the battery

6 FAQs about [Does the lithium battery pack have reverse charge protection ]

What is cell reversal in lithium ion batteries?

Although "Cell reversal" is less common in lithium-ion batteries compared to nickel-based batteries, it is still essential to understand its causes, consequences, and prevention methods. Cell reversal, or polarity reversal, occurs when the voltage of an individual cell within a battery pack drops below zero volts during discharge.

Why do lithium ion batteries reversal?

d) Prolonged storage: When lithium-ion batteries are stored for extended periods without use or proper maintenance, self-discharge can cause some cells to become weaker than others. These imbalanced cells are then more susceptible to cell reversal during discharge. Consequences of Cell Reversal in Lithium-ion Batteries:

What is the difference between a pack+ and a reversed Charger?

The negative voltage is dropped across the R resistor rather than the R DSG GS resistor. With the negative voltage on PACK+, the discharge FET sees the sum of the battery and charger voltages and must be specified with a suitable V DS voltage. The reversed charger carries the sum of the current from the DSG and PACK pin nodes.

What is reverse battery protection?

One essential aspect often overlooked is reverse battery protection—a fundamental mechanism that ensures longevity and safety in solar battery charging setups. This guide will walk you through everything you need to know about reverse battery protection, its significance in solar applications, and how to implement it effectively.

Can a battery be reversed if polarity is reversed?

So reverse charging of the battery occurs only when the polarity of the charging circuit is reversed. However, it is impossible that the "+/-" power trail would be reversed and the component failure would result in reverse charging. Protection against overcharging/ discharging and overcurrent have been employed.

How do you protect a reverse battery?

There are several techniques to achieve reverse battery protection, each with its advantages and applications. Let’s explore some of the most common methods: The diode is one of the simplest yet effective tools for reverse protection. It allows current to flow in only one direction, preventing any reverse flow that could damage your system.

Learn More

- 6-series lithium battery pack protection IC

- High voltage lithium battery pack protection solution

- Lima lithium battery pack temperature protection point

- Bishkek battery pack lithium battery container

- Lithium battery pack judgment

- Tajikistan low rate lithium battery pack

- 60V 50A lithium battery pack

- 4 5v lithium battery pack

- Zhongke lithium battery pack

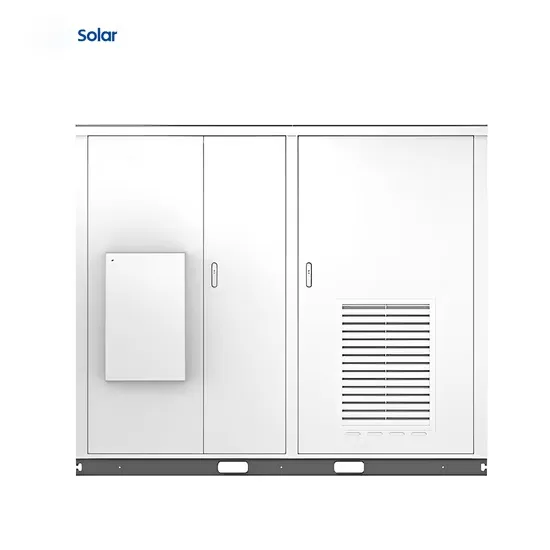

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.