Crash Safety of Lithium-Ion Batteries for Electric Vehicles

Aug 18, 2025 · How much deformation/force a cell can tolerate before reaching internal short circuit? Vehicle crashes are inevitable. Often battery packs are also damaged in case of a

Research on overcharge thermal runaway behavior analysis

Aug 22, 2024 · During the charging process, lithium-ion batteries may experience thermal runaway due to the failure of overcharging protection mechanisms, posing a significant fire

Criteria and design guidance for lithium-ion battery safety

With the rapid development of electric vehicles (EVs) and electronic devices in current mobile society, the safety issues of lithium-ion batteries (LIBs) have attracted worldwide attention.

Model-constrained deep learning for online fault diagnosis

Feb 14, 2025 · In this work, we employ deep learning methods to develop an online fault diagnosis network for lithium-ion batteries operating under unpredictable conditions. The

Life Cycle Assessment of a Lithium‐Ion Battery

Nov 1, 2013 · In order to avoid problem shifting, a life cycle perspective should be applied in the environmental assessment of traction batteries. The aim of this

Development and Commercial Application of

Mar 5, 2025 · In this paper, lithium-ion batteries are reviewed from the perspective of battery materials, the characteristics of lithium-ion batteries with different

Model-constrained deep learning for online fault diagnosis

Feb 14, 2025 · Here, authors employ deep learning methods to develop an online fault diagnosis network for lithium-ion batteries operating under unpredictable conditions, offering

Numerical study of critical conditions for thermal runaway of lithium

Apr 20, 2024 · Considering the effects of heat shield plate on the self-ignition behavior of battery pack, it is found that the graphite composite sheet is more suitable for battery pack storage

(PDF) Failure assessment in lithium-ion battery packs in

Jul 31, 2023 · comprehensive analysis of potential battery failures is carried out. This research examines various failure modes and the ir. effects, investigates the causes behind them, and

Research on overcharge thermal runaway behavior analysis

Aug 22, 2024 · This work by analyzing the evolution of surface temperature, space temperature, and voltage of ternary lithium battery pack under different overcharging rates, a three-level

Unsupervised learning for lithium-ion batteries fault

Feb 15, 2025 · Zhao et al. [19] proposed a gated recurrent unit network combined with an ensemble multi-step prediction technique, effectively identifying battery overvoltage, under

Fault diagnosis method for lithium-ion batteries in electric

Aug 15, 2022 · Failure of the Lithium-ion (Li-ion) battery pack can affect electric vehicles'' safe and reliable operation. Accurate detection of early battery pack failures can prevent safety

Leading Battery Pack Manufacturers in China: A

May 4, 2025 · Fun Fact: Lishen has been a pioneer in the battery industry for over two decades, consistently pushing the boundaries of what''s possible with

Court limits fire and battery expert testimony in fatal laptop battery

Sep 8, 2023 · Court finds enough expert testimony admissible over fire''s origin and laptop battery as cause to deny HP summary judgment on subrogation claim related to 2015 Washington

Lithium phosphate iron battery pack balanced charging

The capacity difference between monomer lithium batteries is the most fundamental reason that causes excessive charging and excessive discharge of monomer batteries. One of the

Lithium battery judgment basis

Keywords: lithium-ion battery; current collector; circumferential strain; failure criterion; mechanical property 1. Introduction A lithium-ion battery (LIB) is a rechargeable secondary battery, also

Liquid-cooled energy storage battery pack capacity judgment

What is the performance evaluation system of lithium-ion battery pack? Finally, the performance evaluation system of the thermal management scheme of the lithium-ion battery pack is

Effective weight-reduction

Oct 1, 2021 · This means a lightweight battery pack enclosure (BPE) design is desirable for maintaining a long range and good safety level, but a good crashworthiness performance also

Lithium Ion Battery Won''t Hold Charge-Fixing And Judgement

Jan 2, 2020 · Lithium ion batteries are expensive pieces of equipment, so if you''ve got a battery that doesn''t hold charge can be fixed and recovered. Thankfully, there are many ways that

Multi-fault diagnosis of lithium battery packs based on

Nov 10, 2024 · The diagnosis of faults in lithium-ion battery packs is pivotal to ensuring the operational safety of electric vehicles. A fault diagnosis method is i

Capacity evaluation and degradation analysis of lithium-ion battery

Aug 15, 2023 · In this paper, a capacity calculating method specialized for EVs is proposed. This method uses an open circuit voltage (OCV) correction strategy to guarantee the credibility of

Fault diagnosis and abnormality detection of lithium-ion battery

Jan 15, 2021 · Lithium-ion battery packs are widely deployed as power sources in transportation electrification solutions. To ensure safe and reliable operation of b

A multi-fault diagnosis method for lithium-ion battery pack

Sep 1, 2023 · In order to ensure the safety and reliability of electric vehicles, and also to reduce the occurrence of accidents, a fast and efficient multi-fault diagnosis methodology for lithium

Lithium-Ion Battery Pack Robust State of Charge Estimation,

Mar 24, 2021 · This paper presents the state of art of battery pack SOC estimation methods along with the impact of cell inconsistency on pack performance and SOC estimation. Cell balancing

Research progress in fault detection of battery systems: A

Sep 15, 2024 · Firstly, the fault information of lithium-ion battery pack is collected by battery testing equipment, with four parameters and six variables (single voltage L1L2, battery voltage

An intelligent fault diagnosis method for lithium-ion battery pack

Nov 15, 2023 · An Intelligent Fault Diagnosis Method for Lithium-ion Battery Pack Based on empirical mode decomposition and Convolutional Neural Network is proposed.

Comprehensively analysis the failure evolution and safety

Nov 1, 2021 · The failure of lithium-ion batteries (LIBs) is the root of most accidents. Although many standards have been made, the battery system''s safety still lacks scientific,

Online surface temperature prediction and abnormal diagnosis of lithium

Mar 1, 2024 · In [8], a thermal-electrical model is established for the lithium-ion battery pack, and particle filter (PF) is applied to predict the temperature and voltage of the battery pack. On this

Judgment of Critical Condition for Crash Safety of Lithium

Oct 9, 2021 · The results show that in the condition of battery pack impacting rigid wall, the second and third rows of battery pack near rigid wall begin to fail when the impact speed

6 FAQs about [Lithium battery pack judgment]

Are lithium-ion batteries safe?

With the rapid development of electric vehicles (EVs) and electronic devices in current mobile society, the safety issues of lithium-ion batteries (LIBs) have attracted worldwide attention. Mechanical, electrochemical, and thermal abusive loading are three leading factors that trigger the safety issues of ba Electric vehicles and batteries

Can a lithium-ion battery overcharge at 25 °C?

To simulate the thermal runaway of a single cell in the lithium-ion battery pack, this work carried out four different charging rates of overcharging experiments on a single lithium-ion battery in the ternary lithium-ion battery pack at 25 °C.

What are lithium-ion battery packs?

Lithium-Ion battery packs are an essential component for electric vehicles (EVs). These packs are configured from hundreds of series and parallel connected cells to provide the necessary power and energy for the vehicle. An accurate, adaptable battery management system (BMS) is essential to monitor and control such a large number of cells.

Are lithium-ion batteries a problem?

However, there are still many issues facing lithium-ion batteries. One of the issues is the deposition of metallic lithium on the anode graphite surface under fast charging or low-temperature conditions. Lithium plating reduces the battery life drastically and limits the fast-charging capability.

What are the technical challenges faced by lithium-ion batteries?

Finally, we highlighted some of the remaining technical challenges and potential solutions for future advancement. Internal short circuit (ISC) of lithium-ion battery is one of the most common reasons for thermal runaway, commonly caused by mechanical abuse, electrical abuse and thermal abuse.

Why do lithium-ion batteries runaway?

In practical applications, lithium-ion battery packs may experience cascading thermal runaway events due to anomalies such as overcharging in individual lithium cells, leading to incalculable losses.

Learn More

- Is there lithium phosphorus lithium battery pack processing in Malta

- Which lithium battery pack is cheaper in New York USA

- Bangji RV lithium battery pack

- 4 5v lithium battery pack

- 72200 Lithium battery pack structure

- Lithium battery pack 8s

- Expand the capacity of lithium battery pack

- North Macedonia liquid-cooled energy storage cabinet system lithium battery pack

- Liberia electric storage vehicle lithium battery pack

Industrial & Commercial Energy Storage Market Growth

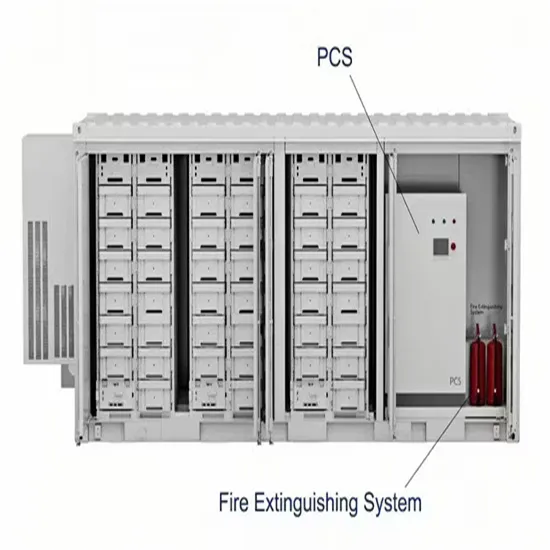

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

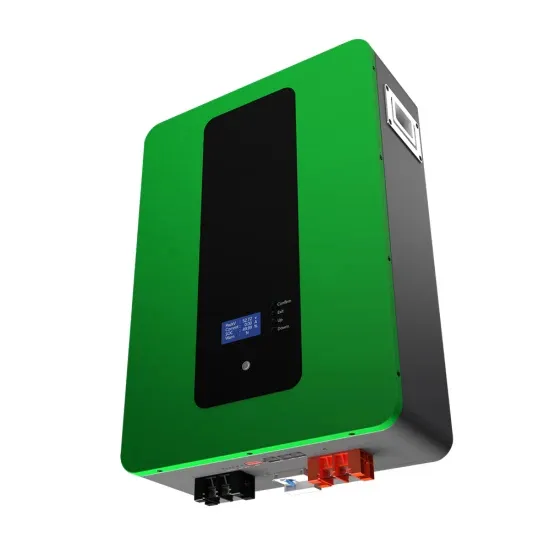

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.