Integration issues of lithium-ion battery into electric vehicles

Feb 1, 2016 · In this work, the integration of Lithium-ion battery into an EV battery pack is investigated from different aspects, namely different battery chemistry, cell packaging, electric

Africa must assume its place in the global battery race

Jul 26, 2022 · The battery market is booming. The global transition towards cleaner fuels has spurred the demand for electric vehicles and investment in battery-powered storage systems.

Neev liberia: pioneering electric vehicle solutions

Sep 24, 2024 · To combat these issues, NEEV is focusing on the development and deployment of electric vehicles that are both affordable and accessible to

Lithium Iron Phosphate Battery Packs: Powering the Future of Energy Storage

Apr 22, 2025 · 1. Introduction In the dynamic landscape of energy storage technologies, lithium - iron - phosphate (LiFePO₄) battery packs have emerged as a game - changing solution.

Liberia EV Battery Pack Market (2025-2031) | Trends,

Market Forecast By Type (Lithium-Ion Pack, Solid-State Pack, Nickel-Metal Hydride Pack, Lead-Acid Pack), By Battery Chemistry (Electric Cars, Heavy Duty Trucks, Buses, E-scooters), By

Liberia Energy Storage Technology: Powering the Future

With 63% of Liberians still lacking reliable electricity access [1], the race is on to deploy storage systems that make solar and wind power available 24/7. Buckle up as we explore how lithium

Liberia liquid-cooled energy storage lithium battery pack

A state-of-the-art review on numerical investigations of liquid-cooled battery thermal management systems for lithium-ion batteries of electric vehicles. Author links open overlay panel Ashutosh

Liberia electric vehicle energy storage

Liberia electric vehicle energy storage Can EV batteries supply short-term storage facilities? For higher vehicle utilisation,neglecting battery pack thermal management in the degradation

Design, Optimization, and Analysis of Electric vehicle

Jun 8, 2022 · Abstract - Lithium-ion batteries are used for their high energy efficiency and are frequently used by electric car manufacturers typically employ them (EVs). However, abrupt

Trends in electric vehicle batteries – Global EV

2 days ago · More batteries means extracting and refining greater quantities of critical raw materials, particularly lithium, cobalt and nickel Rising EV battery

Ranking of Liberia s energy storage battery companies

LG Energy Solution, with extensive experience and a robust global network, is a key player in the lithium-ion battery market, focusing on electric vehicle, mobility, IT, and

Failure assessment in lithium-ion battery packs in electric vehicles

Jul 31, 2023 · The battery pack is the most vital and precarious part of a battery-powered electric vehicle, which necessitates accurate and reliable designs to ensure acceptable safety.

Lithium-Ion Battery Packs for Electric Vehicles

May 20, 2025 · Lithium-ion battery packs are the heart of modern electric vehicles (EVs), powering their propulsion systems and enabling sustainable transportation. These battery

Design approaches for Li-ion battery packs: A review

Dec 20, 2023 · The target concerns electric and hybrid vehicles and energy storage systems in general. The paper makes an original classification of past works defining seven levels of

Liberia electric vehicle energy storage

The global electric car fleet exceeded 7 million battery electric vehicles and plug-in hybrid electric vehicles in 2019, and will continue to increase in the future, as electrification is an important

Electric vehicle power lithium-ion battery pack

Apr 14, 2025 · In the pre-architecture development of pure electric vehicle projects, reasonably arranging the integrated power lithium-ion battery pack is

ELECTRIC VEHICLES PAVE THE WAY FOR A GREENER FUTURE IN LIBERIA

ELECTRIC VEHICLES PAVE THE WAY FOR A GREENER FUTURE IN LIBERIA What electric vehicles can lithium batteries be used for As of 2024, the (LIB) with the variants Li-NMC, LFP

Overview of batteries and battery management for electric vehicles

Nov 1, 2022 · This critical review envisions the development trends of battery chemistry technologies, technologies regarding batteries, and technologies replacing batteries. Wherein,

liberia lithium-iron-phosphate batteries lfp

The Rise of The Lithium Iron Phosphate (LFP) Battery Last April, Tesla announced that nearly half of the electric vehicles it produced in its first quarter of 2022 were equipped with lithium iron

Affordable EV & Solar Batteries | Electric Car

2 days ago · We are experts in EV lithium batteries & packs, management systems, J1772 chargers & sockets, DC-DC Converters & DC inverters, solar

Integration issues of lithium-ion battery into electric vehicles

Feb 1, 2016 · We investigated the integration issues of Li-ion battery into the battery pack. We used various packaging of LiFePO 4 to benchmark the integration process. We analyzed the

Lithium Battery Cell, Module, EV Battery System Manufacturer

LITHIUM STORAGE is a lithium technology provider. LITHIUM STORAGE focuses on to deliver lithium ion battery, lithium ion battery module and lithium based battery system with BMS and

The Handbook of Lithium-Ion

Aug 16, 2025 · The Handbook of Lithium-Ion Battery Pack Design This page intentionally left blank The Handbook of Lithium-Ion Battery Pack Design Chemistry, Components, Types and

6 FAQs about [Liberia electric storage vehicle lithium battery pack]

Are Li-ion batteries compatible with EV battery packs?

However, relatively little attention is paid to the integration issues of batteries into battery packs. There are very few relevant works on the integration issues of Li-ion battery into the EV battery pack available in literature.

How much does a Li-ion battery cost?

Currently, Li-ion batteries are priced at USD 410 per kWh and the long-term goal is targeted at USD 150 per kWh. In addition, Li-ion battery with high voltage and high energy density is needed to reduce the number of cells connected in series for the use in the energy storage system in EVs.

What causes electrical unbalance in a lithium ion battery pack?

Conceptual scheme for lithium-ion battery pack ( Van Schalkwijk and Scrosati, 2002 ). Electrical unbalance of the cells in the battery pack may be caused by different cell SOC, current leakage, different internal resistances or capacity.

Which battery pack has the lowest packing density?

Packing density of the 18650 cell battery pack is about 47,524.75 cell/m 3, followed by the 26650 cell battery pack with packing density of 22,857.14 cell/m 3 and the large prismatic cell battery pack has the lowest packing density of 416.6667 cell/m 3.

What is an electrically balanced battery pack?

An electrically balanced battery pack will have all cells at equal capacity to the weakest cell. Voltage variation on the cells in the battery pack is normally kept at less than 50 mV.

How much does a battery pack assembly cost?

The assembly cost of the battery pack is directly proportional to the number of cells, interconnections, battery holders, BMSs and thermal management systems used in the battery pack. Assembly of one unit of the 18650 cell battery pack by excluding BMS will cost USD 424.32 and 85 man hours are required.

Learn More

- Copenhagen electric storage vehicle lithium battery pack

- Rabat electric storage vehicle lithium battery pack

- Masai electric storage vehicle lithium battery pack

- Electric impact rammer lithium battery pack

- Electric lithium battery pack

- Democratic Republic of Congo Electric Stacker Lithium Battery Pack

- North Macedonia liquid-cooled energy storage cabinet system lithium battery pack

- Liechtenstein electric forklift lithium battery pack

- Lithium battery energy storage for electric vehicles

Industrial & Commercial Energy Storage Market Growth

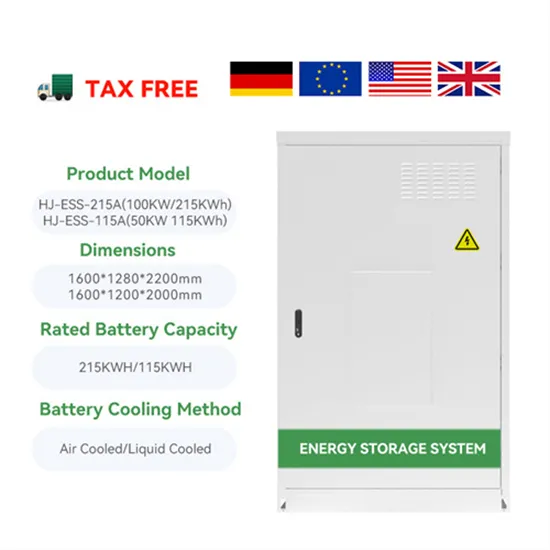

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.