Enhancing thermal performance for electric vehicle lithium-ion battery

Aug 1, 2025 · Lithium batteries, with their superior energy density, lightweight characteristics, and long cycle life, are now the primary choice for powering electric vehicles [3, 4]. Lithium battery

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Electric Car Battery Life: How Long They Last and

May 10, 2024 · The battery packs of electric vehicles are quite resilient, with the lithium-ion type used in most modern EVs capable of lasting at least a decade

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · This final stage in the lithium-ion battery manufacturing process integrates individual cells into fully functional battery modules, complete with

Lithium Battery Pack: The Ultimate Guide to Powering Our

Apr 16, 2025 · A lithium battery pack is a collection of individual lithium-ion cells connected in series or parallel to provide higher voltage, capacity, or power output. Unlike single-cell

High-Performance Battery Packs for Electric Vehicles

PHYLION''s battery packs are designed to revolutionize electric mobility. Our 48V 12Ah packs power toys and uninterruptible power supplies, while 25Ah LFP cells drive golf carts and

Top 10 Global EV/REEV Battery Pack Suppliers – LEAPENERGY

Jul 21, 2025 · LEAPENERGY stands at the forefront of global battery pack suppliers, offering advanced lithium-ion modules and systems optimized for electric vehicles (EVs), energy

EV Lithium Battery PACK Design Process from Manufacturers

Mar 18, 2025 · At Bonnen Battery, our engineering team follows a systematic approach to battery pack design, ensuring optimal performance and safety for various EV applications. This blog

What to Know About Lithium Battery Packs: Key

Aug 5, 2024 · Lithium-ion battery packs are versatile and used across numerous industries: Electric Vehicles (EVs): Powering modern electric cars, bikes, and

Lithium-Ion Battery Packs for Electric Vehicles

May 20, 2025 · Lithium-ion battery packs are the heart of modern electric vehicles (EVs), powering their propulsion systems and enabling sustainable transportation. These battery

Amazon : 48v Lithium Ion Battery Pack

48V 20Ah Lithium Ion Battery for Ebike & Scooter - High Power 1000W 13S3P Battery Pack with BMS, Charger & XT60 Connector - Perfect for Electric Bicycles, Long-Lasting Performance

6 FAQs about [Electric lithium battery pack]

What is a lithium-ion battery pack?

The Lithium-Ion battery packs at La-Z-Boy have multiple functionalities. Here are some of them in a nutshell Works with all La-Z-Boy power recliners, sofas, and sectionals (excluding lift chairs). Red flashing light while charging, green steady light when fully charged (approx. 5-7 hours charge time).

Why do electric vehicles need lithium battery packs?

The design of Electric Vehicle (EV) lithium battery packs ⇱ is a complex and critical process that directly impacts vehicle performance, safety, and cost-effectiveness. As the demand for electric vehicles continues to grow worldwide, the need for high-quality, reliable, and efficient battery packs has never been more important.

How do you design a custom lithium battery pack?

This blog post outlines the comprehensive design process we follow when developing custom lithium battery packs for our clients. The first and foundational step in battery pack design is a thorough analysis of requirements and specification definition. This initial phase sets the direction for the entire design process.

How big is the lithium-ion battery market?

And this market isn’t slowing down anytime soon— it’s projected to grow steadily, reaching around $88.46 billion by 2033, with a yearly growth rate of 3.4% over the next decade. China has become the center of this lithium-ion battery industry, home to many of the world’s top lithium battery manufacturers.

What is China's Lithium-ion battery industry?

China has become the center of this lithium-ion battery industry, home to many of the world’s top lithium battery manufacturers. These companies are leading the way in battery tech, creating everything from compact batteries for light electric vehicles to powerful systems that store renewable energy.

Why are lithium-ion batteries so important?

Lithium-ion batteries have become a big part of everyday life. They’re in the phones we check constantly, the electric cars hitting the roads, and even in systems that store solar power for homes.

Learn More

- Specialized in 60v lithium battery pack for electric tools

- Liechtenstein electric forklift lithium battery pack

- Electric impact rammer lithium battery pack

- Democratic Republic of Congo Electric Stacker Lithium Battery Pack

- Electric forklift lithium battery pack

- Copenhagen electric storage vehicle lithium battery pack

- Masai electric storage vehicle lithium battery pack

- Does the lithium battery pack have reverse charge protection

- Lithium battery pack serial charging

Industrial & Commercial Energy Storage Market Growth

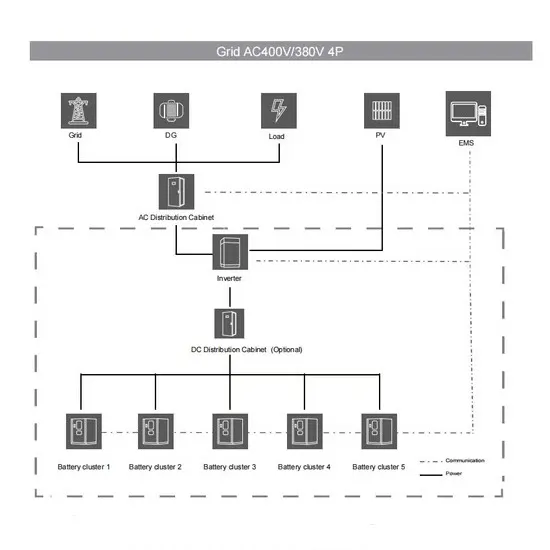

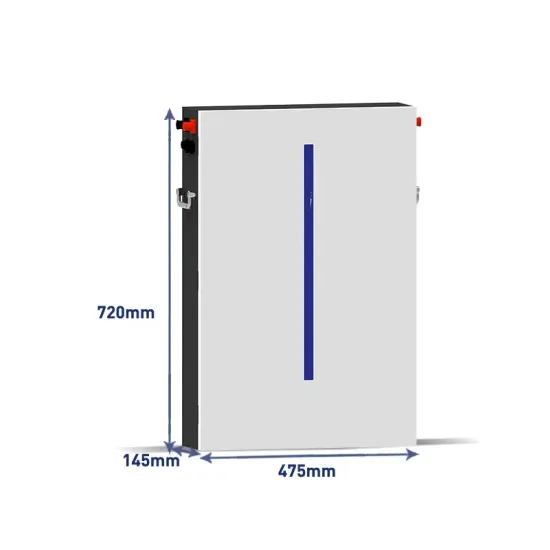

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.