Battery Pack, Lithium Battery Manufacturer

The typical products are PV inverter, storage inverter, lithium battery pack and EV charger that are widely applied to household, industrial and commercial new energy systems. Sunplus

Lithium Battery Cell, Module, EV Battery System Manufacturer

LITHIUM STORAGE is a lithium technology provider. LITHIUM STORAGE focuses on to deliver lithium ion battery, lithium ion battery module and lithium based battery system with BMS and

Masai Lithium Battery Pack Factory Powering the Future of

May 20, 2025 · In today''s fast-evolving energy landscape, the Masai lithium battery pack factory serves as a key player for multiple industries. From solar farms needing reliable storage to

Masai energy storage lithium battery price

Feb 25, 2022 · The Price Range of 200 kWh Batteries: An In-depth Analysis Lithium-ion batteries are one of the most common types used for energy storage applications, including 200 kWh

Storage technologies for electric vehicles

Jun 1, 2020 · It also presents the thorough review of various components and energy storage system (ESS) used in electric vehicles. The main focus of the paper is on batteries as it is the

Design approach for electric vehicle battery packs based on

Jan 30, 2024 · In recent years, vehicle manufacturers have shifted their attention towards eco-friendly transport systems mainly based on Electric Vehicles (EVs), which appear to be the

Affordable EV & Solar Batteries | Electric Car

2 days ago · We are experts in EV lithium batteries & packs, management systems, J1772 chargers & sockets, DC-DC Converters & DC inverters, solar

Top 10 Global EV/REEV Battery Pack Suppliers – LEAPENERGY

Jul 21, 2025 · In this blog, we explore the top 10 global battery pack suppliers—industry leaders who are shaping the future of mobility and energy with cutting-edge technology, mass

Li-ion Battery Packs for Automotive and Stationary

Nov 21, 2022 · Determine the market value for lithium-ion (Li-ion) battery packs and their components including battery management system, thermal management, safety components

Integration issues of lithium-ion battery into electric vehicles

Feb 1, 2016 · We investigated the integration issues of Li-ion battery into the battery pack. We used various packaging of LiFePO 4 to benchmark the integration process. We analyzed the

Failure assessment in lithium-ion battery packs in electric vehicles

Jul 31, 2023 · The battery pack is the most vital and precarious part of a battery-powered electric vehicle, which necessitates accurate and reliable designs to ensure acceptable safety.

Traction Battery Packs for High-Performance

Nov 30, 2024 · The Role of Traction Battery Packs in Electric Vehicles Traction battery packs are the energy storage systems that power the electric drivetrain

Trends in electric vehicle batteries – Global EV

Aug 14, 2025 · More batteries means extracting and refining greater quantities of critical raw materials, particularly lithium, cobalt and nickel Rising EV battery

Lithium Ion Battery Pack Manufacturer | Custom

2 days ago · Our battery solutions are widely applied in Electric Vehicle Lithium Batteries, Electric boats, Energy Storage systems etc. We have supplied to

Masai high rate lithium battery pack

How does discharge rate affect thermal performance of lithium-ion batteries? Discharge rate showed the highest contribution followed by electrical configuration. Discharge rate impacts T

Solar Energy Equipment, Lithium Battery, Hybrid Inverter,

The typical products are PV nverter, storage inverter, lithium battery pack and EV charger that are widely applied to household, industrial and commercial new energy systems. Sunplus

6 FAQs about [Masai electric storage vehicle lithium battery pack]

How can mechanical design and battery packaging protect EV batteries?

Robust mechanical design and battery packaging can provide greater degree of protection against all of these. This chapter discusses design elements like thermal barrier and gas exhaust mechanism that can be integrated into battery packaging to mitigate the high safety risks associated with failure of an electric vehicle (EV) battery pack.

Can Li-ion battery be integrated into a battery pack?

We investigated the integration issues of Li-ion battery into the battery pack. We used various packaging of LiFePO 4 to benchmark the integration process. We analyzed the heat generated of the battery pack using the NEDC test. We analyzed the assembly efficiency for various types of Li-ion cell packaging. 1. Introduction

Can mechanical design improve EV battery pack crashworthiness & vibration isolation?

Several patented mechanical design solutions, developed with an aim to increase crashworthiness and vibration isolation in EV battery pack, are discussed. Lastly, mechanical design of the battery pack of the first fully electric bus designed and developed in Australia is presented.

How much does a battery pack assembly cost?

The assembly cost of the battery pack is directly proportional to the number of cells, interconnections, battery holders, BMSs and thermal management systems used in the battery pack. Assembly of one unit of the 18650 cell battery pack by excluding BMS will cost USD 424.32 and 85 man hours are required.

Which battery pack has the lowest packing density?

Packing density of the 18650 cell battery pack is about 47,524.75 cell/m 3, followed by the 26650 cell battery pack with packing density of 22,857.14 cell/m 3 and the large prismatic cell battery pack has the lowest packing density of 416.6667 cell/m 3.

What is an electrically balanced battery pack?

An electrically balanced battery pack will have all cells at equal capacity to the weakest cell. Voltage variation on the cells in the battery pack is normally kept at less than 50 mV.

Learn More

- Copenhagen electric storage vehicle lithium battery pack

- Rabat electric storage vehicle lithium battery pack

- Liberia electric storage vehicle lithium battery pack

- Lithium battery pack electric wheel

- Electric forklift lithium battery pack

- Sana Energy Storage Lithium Battery Pack Processing

- Specialized in 60v lithium battery pack for electric tools

- Electric impact rammer lithium battery pack

- Czech household energy storage lithium battery pack

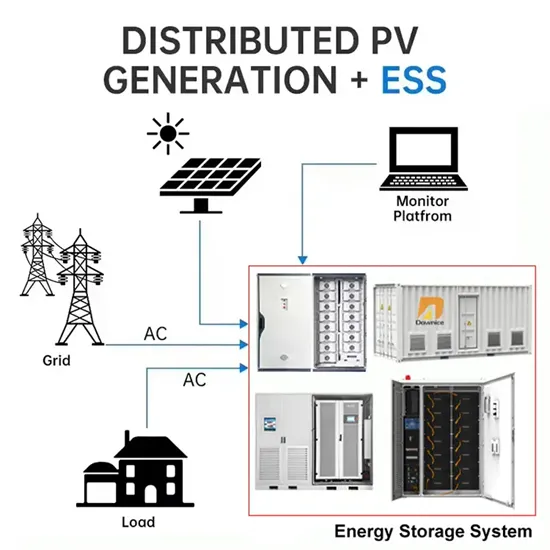

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.