The Construction of a Lithium-Ion Battery Pack: An In-Depth

Jun 19, 2025 · From electric vehicles to portable electronics, these batteries are renowned for their efficiency, energy density, and longevity. This article delves into the intricate construction

Introduction to Power Battery Packs-JONVER

Apr 10, 2025 · Current battery pack integration technologies have evolved through three main stages: MTP, CTP, and CTC. Structure: Traditional design where multiple cells form a module,

In-depth analysis of electric vehicles battery pack structure

Jan 1, 2024 · The battery pack is the most valuable component of the electric vehicle and its disassembly is the key process to recover the inner value of the product and apply circular

A review on structure model and energy system design of lithium

Sep 1, 2014 · Abstract Structure properties of lithium-ion battery determine the specific energy and specific power of renewable energy vehicle and have attracted extensive concerns.

The Handbook of Lithium-Ion

Aug 16, 2025 · The Handbook of Lithium-Ion Battery Pack Design This page intentionally left blank The Handbook of Lithium-Ion Battery Pack Design Chemistry, Components, Types and

INSTRUCTION MANUAL: BATTERY PACK DESIGN, BUILD

Apr 29, 2021 · install partitions between BMS and cells check if the pack is designed to be able to avoid thermal runaway analyze the battery pack''s thermal distribution and its effect on the

Structural optimization of lithium-ion battery pack with

Nov 5, 2017 · The forced air cooling system is of great significance in the battery thermal management system because of its simple structure and low cost. The influences of three

Introduction and Application Analysis of 72200 Super Large

The 72200-specification super-large power lithium battery can meet the demand of these electric vehicles for high power output and long endurance mileage, providing reliable power

Battery Circuit Architecture

Aug 6, 2011 · I. TYPICAL BATTERY CIRCUITRY FOR A LI-ION BATTERY PACK Fig. 1 is a block diagram of circuitry in a typical Li-ion battery pack. It shows an example of a safety protection

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Introduction to Power Battery Packs-JONVER

Apr 10, 2025 · Widely adopted by Tesla (Model 3/Y), XPeng (P7), NIO (ES6), and others. CTC (Cell to Chassis) Structure: Two approaches: Battery-Chassis Integration: The battery pack

6 FAQs about [72200 Lithium battery pack structure]

What are battery pack design criteria & selection 37?

Battery Pack Design Criteria and Selection 37 found in a fully electric vehicle that is designed to achieve long driving ranges. In a grid type application this may come through as a battery backup system designed to provide power for several hours. There is also a third type of application that is not frequently talked about.

Which companies use lithium-ion batteries in space based applications?

Companies such as ABSL, Quallion, Saft, and Mitsubishi Electric have spent many years developing products for use in orbital satellites and other space-based applications. During the battery industry consolidation that occurred in the early 2010s, lead Figure 26 Community energy storage unit. Lithium-Ion Battery Applications 207

Is there a standard size lithium-ion battery pack?

Perhaps the first and most important statement we can make about battery packaging is this: there is no standard size lithium-ion battery pack and there is not likely to be one in the near future.

Are there any sizing tools for lithium-ion batteries?

When it comes to lithium-ion battery sizing tools, there are not currently any industry stan- dards developed in order to assist the system designer in generating an initial specification for a lithium-ion-based energy storage system. This is a weakness in the current literature on the Computer-Aided Design and Analysis 63 subject.

What are the challenges in designing a large lithium-ion battery?

One of the great challenges in designing a large lithium-ion battery is estimating and calculat- ing the reliability and lifetime of the energy storage system. This is in large part due to the fact that there is not yet enough history on this technology that is available to be able to base future predictions on past performance.

Are all lithium-ion batteries compatible?

While this may seem like a “no brainer,” the lithium-ion battery industry is only just beginning to get to some level of standardization so there are still many solutions available and each has different costs/benefits—and they are not all compatible with each other!

Learn More

- Rechargeable lithium battery pack structure

- Nicaragua 21700 lithium battery pack manufacturer

- Electric impact rammer lithium battery pack

- 3 series and two parallel lithium battery pack

- What shock absorption is used for lithium battery pack

- Stockholm Solar Lithium Battery Pack Parameters

- Battery pack uses lithium battery

- Class 9 lithium battery pack identification

- Lithium battery pack internal parallel connection

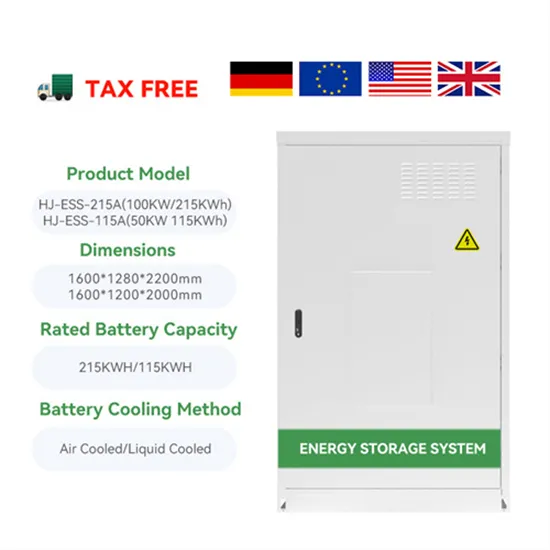

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.