Material design and structure optimization for rechargeable lithium

Apr 7, 2021 · Conventional lithium (Li) ion batteries are more and more difficult in satisfying the ever-growing energy demand because they are approaching their theoretical energy density

Structure of Lithium-ion Batteries & How They

Jan 11, 2025 · At their core, lithium-ion batteries are composed of several key components that work together to store and release energy. These include: 1.

Rechargeable Batteries: Understanding Their Structure,

Jan 2, 2025 · A rechargeable battery contains different combinations of electrode materials and electrolytes. Common types include lead-acid, zinc-air, nickel-cadmium (NiCd), nickel-metal

DOE ESHB Chapter 3: Lithium-Ion Batteries

Mar 17, 2021 · The first rechargeable lithium battery, consisting of a positive electrode of layered TiS2 and a negative electrode of metallic Li, was reported in 1976 [3]. This battery was not

Top 10 Applications of Lithium-Ion Batteries in 2025: From

Jun 25, 2025 · A lithium-ion battery is a rechargeable electrochemical device that stores and releases energy by the movement of lithium ions between two electrodes: the anode and the

Lithium Ion Rechargeable Battery Packs | Battery Mart

4 days ago · Shop eco-friendly, long-lasting rechargeable batteries. Find AA, AAA, 9V, and lithium-ion batteries from trusted brands. Save money and get reliable power for all your devices.

Understanding Li-Ion Battery Packs: A Complete Guide

Aug 8, 2024 · To start, let''s clarify what a Li-ion battery pack really is. Essentially, it''s a set of lithium-ion cells working together to provide a stable power source. Each cell is like a tiny

The Handbook of Lithium-Ion Battery Pack Design:

May 16, 2024 · At the same time battery pack technologies have improved and become simpler. These improvements have enabled an entirely new generation of EVs and applications.

How to Build a Lithium Ion Battery Pack: Expert Guide for

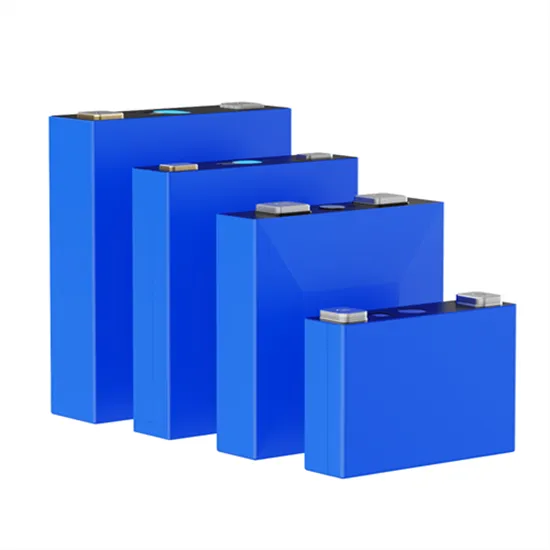

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Lithium-ion battery PACK knowledge comprehensive

Learn more about battery PACK structure. Below are some pictures about the basic structure of electric two-wheeler lithium battery PACK: At present, Tritek can provide a full range of

EV battery pack structure. Adapted with permission.[¹⁰] To

Adapted with permission. [¹⁰] To categorize battery systems and LIB components to analyze fire causes, highlighting pack module, thermal management, electrical systems, and BMS. from

The Construction and Working of a Lithium Ion Battery: A

Jun 19, 2025 · The Construction and Working of a Lithium Ion Battery: A Detailed Guide Are you curious about the small but powerful device that powers your smartphones, laptops and

Lithium-Ion Battery Packs for EVs

Jan 1, 2014 · Battery pack development for electric vehicles (EVs) and plug-in hybrid electric vehicles (PHEVs) includes many of the same considerations involved in the development of

The Construction of a Lithium-Ion Battery Pack: An In-Depth

Jun 19, 2025 · From electric vehicles to portable electronics, these batteries are renowned for their efficiency, energy density, and longevity. This article delves into the intricate construction

6 FAQs about [Rechargeable lithium battery pack structure]

What is a lithium ion battery pack?

Lithium-ion battery packs include the following main components: Lithium-ion cells – The basic electrochemical unit providing electrical storage capacity. Multiple cells are combined to achieve the desired voltage and capacity. Battery Management System (BMS) – The “brain” monitoring cell conditions and controlling safety and performance.

What are layered structures in lithium ion batteries?

The layered structures produce cells with sloping voltage profiles, where cell balancing is straightforward at any state of charge. The positive electrodes that are most common in Li-ion batteries for grid energy storage are the olivine LFP and the layered oxide, LiNixMnyCo1-x-yO2 (NMC).

How to use lithium-ion batteries correctly?

How to use lithium-ion batteries correctly? Avoid excessive discharge. When the device prompts "low battery", it should be charged; Don't charge until the device shuts down automatically. The battery has been discharging excessively. This can affect battery life. Avoid overcharging. The charger should be unplugged when it is indicated to be full.

What is a Li-ion battery pack?

At the base of every Li-ion battery pack is the battery cell or cells. A pack can contain one cell or many cells configured to achieve higher capacity or output voltage. This is achieved by connecting cells in parallel or series, and we’ll explore this much further in our next blog.

What are lithium ion batteries?

Figure. 1 Lithium-ion batteries are rechargeable batteries that mainly rely on lithium ions moving between the positive and negative electrodes to work.

How is Li+ embedded in a battery?

In the process of charging and discharging, Li+ is embedded and de-embedded back and forth between the two electrodes: when charging the battery, Li+ is de-embedded from the positive electrode and embedded in the negative electrode through the electrolyte, which is in a lithium-rich state; when discharging, the opposite is true.

Learn More

- 72200 Lithium battery pack structure

- Tajikistan low rate lithium battery pack

- Mexican lithium battery pack

- Lithium battery pack 8s

- Shallow charge and discharge of lithium battery pack

- Expand the capacity of lithium battery pack

- Is there lithium phosphorus lithium battery pack processing in Malta

- 30a lithium battery pack

- Lithium battery pack parallel power supply

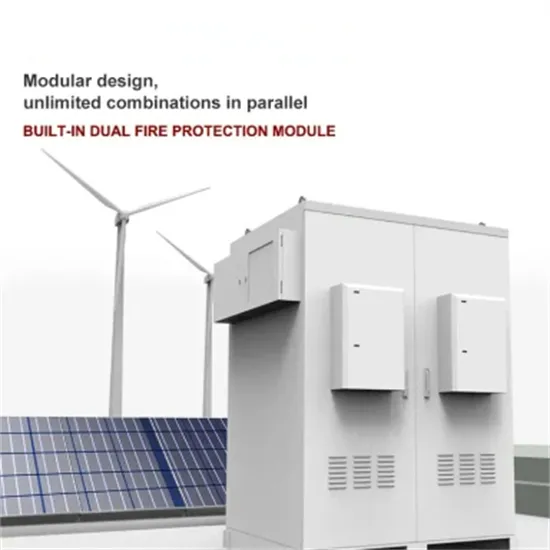

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.