Unlocking the dissolution mechanism of phosphorus anode for lithium

May 1, 2021 · Abstract Phosphorus is a promising anode material for fast-charging in lithium-ion batteries because of the combined advantages of high theoretical mass and volume specific

Study of the direct production of lithium phosphate with

Jul 1, 2022 · This work studies a membrane electrolytic process, where a diluted lithium chloride brine solution is concentrated, while simultaneously producing lithium phosphate. This

Advanced lithium-ion battery process manufacturing

Jul 18, 2025 · Summary Lithium-ion battery cell manufacturing depends on a few key raw materials and equipment manufacturers. Battery manufacturing faces global challenges and

Lithium-ion Battery Pack Manufacturing Process & Design

Jul 28, 2023 · CMB''s battery pack designer gives priority to the following three most common battery cells for the battery pack design: INR (Ternary Lithium), LFP (Lithium Iron Phosphate

PRODUCTION PROCESS OF A LITHIUM-ION BATTERY CELL

Feb 7, 2024 · The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell assembly and cell finishing. The electrode

Lithium‐based batteries, history, current status,

Oct 7, 2023 · The first rechargeable lithium battery was designed by Whittingham (Exxon) and consisted of a lithium-metal anode, a titanium disulphide (TiS 2)

An overview on the life cycle of lithium iron phosphate:

Apr 1, 2024 · Lithium Iron Phosphate (LiFePO4, LFP), as an outstanding energy storage material, plays a crucial role in human society. Its excellent safety, low cos

Analyze the processing materials and assembly prospects of lithium

This article takes you to understand the prospects of lithium battery pack raw materials and assembly processing. With the rapid growth of the market, the domestic lithium battery pack

A review on direct regeneration of spent lithium iron phosphate

Dec 20, 2024 · Abstract Lithium iron phosphate (LFP) batteries are widely used due to their affordability, minimal environmental impact, structural stability, and exceptional safety features.

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · The publication "Production process of a lithium-ion battery cell" provides a comprehensive process overview of the production of different battery cell formats from

How lithium-ion batteries are manufactured

Jul 4, 2025 · How lithium-ion batteries are made in detail—from electrode slurry preparation to final battery pack assembly. Learn about key materials, equipment, and processes used in

How are Lithium-ion Battery Packs Manufactured?

Lithium-ion battery packs are manufactured through a meticulous process that includes two key parts: the Battery Management System (BMS) and the battery pack assembly. The BMS is

Explore LFP Battery Raw Material: LFP Cathode

Jan 30, 2024 · Lithium iron phosphate is an important cathode material for lithium-ion batteries. Due to its high theoretical specific capacity, low manufacturing

Lithium Battery Manufacturing Process Step-by-Step

Aug 4, 2025 · Ufine Battery lithium battery manufacturing process: electrode prep, cell assembly an''d testing. Custom solutions for high-performance batteries.

Lithium iron phosphate (LFP) batteries in EV cars

Apr 3, 2024 · What are the drawbacks of lithium iron phosphate batteries? While LFP batteries have several advantages over other EV battery types, they aren''t perfect for all applications.

Exploring sustainable lithium iron phosphate cathodes for Li

Lithium iron phosphate (LFP) cathodes are gaining popularity because of their safety features, long lifespan, and the availability of raw materials. Understanding the supply chain from mine

6 FAQs about [Is there lithium phosphorus lithium battery pack processing in Malta ]

What is the production process of lithium-ion battery cells?

"Production process of lithium-ion battery cells" , this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

What is a LiFePO4 battery pack?

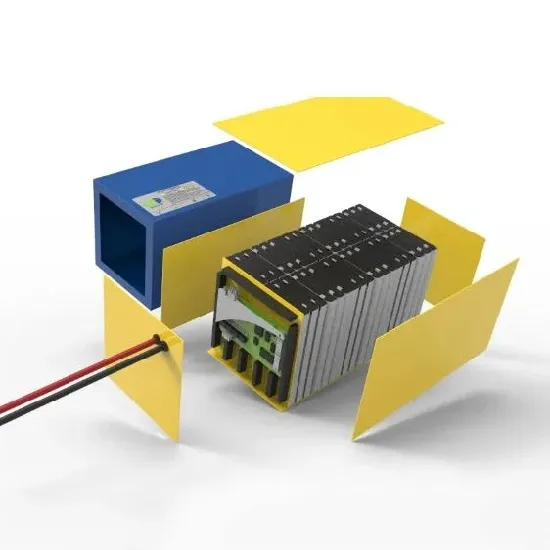

Suitable for a variety of applications, LiFePO4 battery packs offer excellent safety and impressive cycle life, while being lightweight, easy to use and affordable. Lithium iron phosphate battery pack is an advanced energy storage technology composed of cells, each cell is wrapped into a unit by multiple lithium-ion batteries.

What is a lithium iron phosphate battery energy storage system?

The lithium iron phosphate battery energy storage system consists of a lithium iron phosphate battery pack, a battery management system (Battery Management System, BMS), a converter device (rectifier, inverter), a central monitoring system, and a transformer.

What are lithium iron phosphate batteries?

In the current energy industry, lithium iron phosphate batteries are becoming more and more popular. These Li-ion cells boast remarkable efficiency, state-of-the-art technology and many other advantages that have been proven to deliver unprecedented power levels for applications.

Are competencies transferable from the production of lithium-ion battery cells?

In addition, the possible transferability of competencies from the production of lithium-ion battery cells is illuminated. 2ndedition ISBN 978-3-947920-29-7 Ed. PEM of RWTH Aachen University & VDMA

Learn More

- Sana Energy Storage Lithium Battery Pack Processing

- Lithium battery pack 8s

- Which company has the best quality of monitoring lithium battery pack

- What does lithium battery pack gram mean

- Lithuania 71kwh lithium battery pack

- Imported lithium iron phosphate battery pack

- Shallow charge and discharge of lithium battery pack

- Khartoum RV lithium battery pack

- 30a lithium battery pack

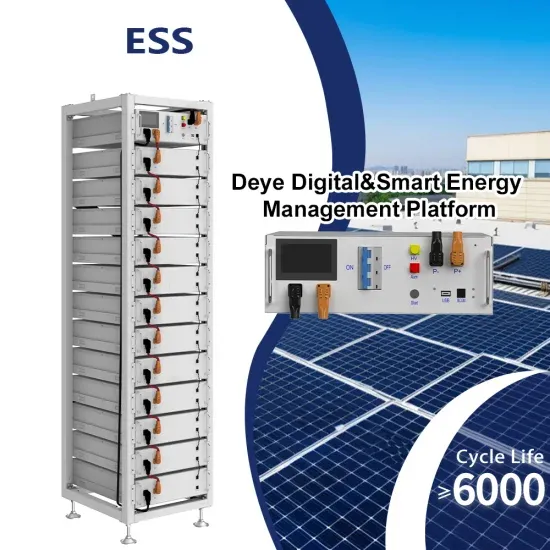

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.