How to Connect Lithium Batteries in Series and Parallel?

Aug 28, 2024 · In this article, we''ll explore the basics and provide detailed, step-by-step instructions on how to connect lithium batteries in series, parallel, and series-parallel

Internal resistance matching for parallel-connected lithium

Apr 15, 2014 · When assembling lithium-ion cells into functional battery packs, it is common to connect multiple cells in parallel. Here we present experimental and modeling results

Connecting batteries in parallel – BatteryGuy

May 3, 2024 · With secondary (rechargeable) batteries – only use batteries of the same brand and age and make sure all the units are fully charged before connecting them together in parallel.

Management of imbalances in parallel-connected lithium-ion battery packs

Aug 1, 2019 · Uneven electrical current distribution in a parallel-connected lithium-ion battery pack can result in different degradation rates and overcurrent issues in the cells. Understanding the

Can a lithium battery pack be used in parallel?

Aug 14, 2025 · For example, if you have two 12 - volt, 10Ah lithium battery packs and you connect them in parallel, you''ll end up with a 12 - volt, 20Ah battery system. This can be super useful in

Performance of LiFePO4 batteries in parallel based on connection

Oct 15, 2019 · Here, a method based on the battery posts position and connector resistance is developed to explain how connection topology affects the performance of LiFePO 4 /graphite

The difference between series and parallel connection of lithium

Apr 22, 2025 · 2. Parallel connection of lithium batteries with different capacities If lithium batteries of different capacities or new and old ones are used together, leakage and zero voltage may

Lithium battery series and parallel, the difference

Aug 1, 2025 · Lithium battery series and parallel definition Due to the limited voltage and capacity of the single battery, in actual use, a series-parallel

Helpful Guide to Lithium Batteries in Parallel and

Apr 23, 2024 · In actual use, lithium batteries need to be combined in parallel and series to obtain a lithium battery pack with a higher voltage and capacity to

What is lithium battery series and parallel connection, series

6 days ago · In a lithium battery pack, several lithium batteries are connected in series to get the required working voltage. If you need higher capacity and higher current, you should connect

Batteries in series vs parallel: what are the

Aug 17, 2024 · 1. What are series and parallel batteries? 1.1 Series Battery Series battery refers to the positive terminal of one battery connected to the negative

Cells in Series and Parallel – NPP POWER

Jun 1, 2023 · The process of assembling lithium cells into a group is called PACK, which can be a single cell or cells in series and parallel lithium battery pack,

Internal short circuit detection for lithium-ion battery pack

May 10, 2020 · Abstract Internal short circuit is one of the unsolved safety problems that may trigger the thermal runaway of lithium-ion batteries. This paper aims to detect the internal short

Can You Safely Connect Two Lithium Batteries in Parallel?

Yes, you can connect two lithium batteries in parallel to increase capacity while maintaining voltage. Ensure both batteries have identical voltage, capacity, and state of charge to prevent

Everything About Lithium Battery Series & Parallel

May 21, 2025 · The series and parallel connection of lithium batteries is a key technology to increase voltage and capacity, but it also contains safety risks. This article will analyze in detail

Current distribution within parallel-connected battery cells

Dec 1, 2016 · By contrast, the battery system of an all-electric Model S by the Tesla Motors Inc. contains several thousand lithium-ion battery cells of the 18650 format with around 70 battery

Influence of connection impedance on the performance of parallel

Feb 15, 2024 · Through EIS analysis, this study identifies the connection quality and locates FECPs within the 2-parallel module. The insights gained from this research offer valuable

How to Connect Lithium Batteries in Parallel?

Feb 12, 2025 · So how do you connect lithium batteries in parallel? The answer is: connecting lithium-ion batteries in parallel means connecting the positive terminals of multiple batteries to

Internal short circuit detection for lithium-ion battery pack

May 10, 2020 · Internal short circuit is one of the unsolved safety problems that may trigger the thermal runaway of lithium-ion batteries. This paper aims to detect the internal short circuit that

Wiring Batteries in Parallel: Understanding the

Jan 4, 2025 · When lithium batteries are wired in parallel, their positive terminals are connected together, and their negative terminals are also linked. This

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

6 FAQs about [Lithium battery pack internal parallel connection]

Are series and parallel connection of lithium batteries safe?

The series and parallel connection of lithium batteries is a key technology to increase voltage and capacity, but it also contains safety risks. This article will analyze in detail the principles, methods and precautions of series and parallel connection of lithium batteries to help you avoid potential risks and build a battery system correctly.

Should you connect lithium batteries in parallel?

Before proceeding with the parallel connection of lithium batteries, it is crucial to keep the following precautions and considerations in mind: Battery Compatibility: Ensure that all the batteries you plan to connect in parallel have the same voltage and capacity ratings. Mismatched batteries can lead to imbalances and potential damage.

How to charge parallel lithium battery packs?

Specific principles must be followed when charging parallel lithium battery packs: Use a matching charger: The voltage must be suitable for the nominal voltage of the individual batteries. The current setting is reasonable: usually 0.2-0.5C of the total capacity after parallel connection.

Why do I need to add batteries in parallel?

If your load requires more current than a single battery can provide, but the voltage of the battery is what the load needs, then you need to add batteries in parallel to increase amperage. Wiring batteries in parallel is an extremely easy way to double, triple, or otherwise increase the capacity of a lithium battery.

Why are lithium batteries connected in series?

Lithium batteries are connected in series when the goal is to increase the nominal voltage rating of one individual lithium battery - by connecting it in series strings with at least one more of the same type and specification - to meet the nominal operating voltage of the system the batteries are being installed to support.

What are the advantages of parallel lithium batteries?

Parallel lithium batteries have many advantages, including increased capacity, enhanced power output, and improved overall performance. When multiple batteries are connected in parallel, their individual ampere-hour (Ah) capacities add up, resulting in a higher total capacity.

Learn More

- Lithium battery pack parallel power supply

- 3 series and two parallel lithium battery pack

- Five parallel four series lithium battery pack

- Montevideo 12v lithium battery pack

- Lithium battery pack judgment

- Which lithium battery pack is cheaper in New York USA

- What does lithium battery pack gram mean

- Tonga 12v lithium battery pack

- Lithuania 71kwh lithium battery pack

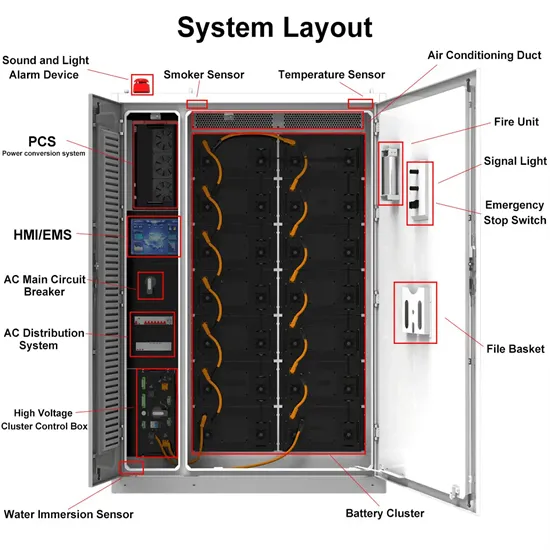

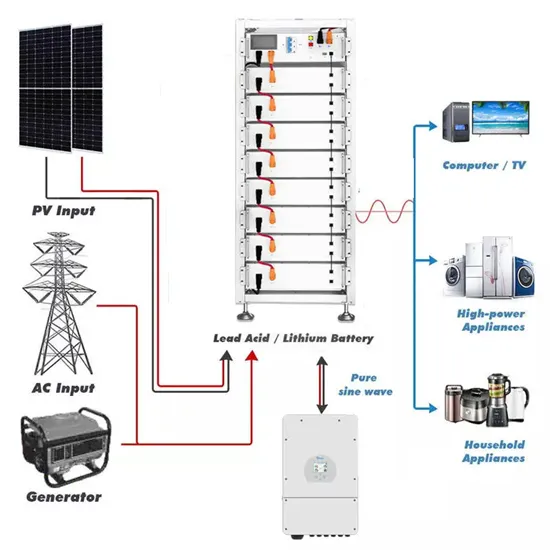

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.