Calculate the number of series and parallel connections for lithium

May 19, 2024 · Series parallel connection of lithium batteries is particularly common in some PACK factories. Generally, lithium battery packs are composed of batteries in series parallel

Connecting batteries in series – BatteryGuy Knowledge

May 3, 2024 · There are two ways to wire batteries together, parallel and series. The illustrations below show how these set wiring variations can produce different voltage and amp hour

Connecting batteries in parallel – BatteryGuy

May 3, 2024 · For more information on wiring in series see Connecting batteries in series, or our article on building battery banks. Connecting in parallel increases amp hour capacity only

Helpful Guide to Lithium Batteries in Parallel and

Apr 23, 2024 · Lithium battery series and parallel: There are both parallel and series combinations in the middle of the lithium battery pack, which increases

Lithium-ion battery pack parallel and series diagram

Connections in Series and Parallel: Series connections enhance voltage, whereas parallel connections increase capacity. Because of its adaptability, designers can customize the

Battery pack five parallel and three series

Here''''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and maximum discharge

Series Parallel Battery Pack Modules Trend in

Jul 20, 2023 · In 2024, more people are opting for parallel, series, and series-parallel lithium-ion battery pack designs for two primary reasons: 1) Batteries

Multibattery management in medical ultrasound systems

Jun 8, 2023 · Some packs comprise both series and parallel connections. For example, a battery pack with four cells in series and two cells in a parallel configuration is called 4S2P (4 series, 2

Parallel Disassembly Sequence Planning of Retired Lithium

Apr 1, 2022 · Parallel Disassembly Sequence Planning of Retired Lithium-ion-battery Pack based on Heuristic Algorithm,Journal of Physics: Conference Series - X-MOL

How to Connect Lithium Batteries in Series and Parallel?

Aug 28, 2024 · A series-parallel connection combines both configurations to increase both voltage and capacity. For example, connecting four 3.7V 100mAh lithium cells in a series-parallel

LiFePO4 Battery Bank in Series (48V or 60V) balancer

Dec 8, 2020 · Hello folks, I intend to series-connect four or five 12V Lithium batteries to make a 48V or 60V bank for my residential solar project. From my reading here and here, I understand

Lithium battery series and parallel, the difference

Aug 1, 2025 · Lithium battery series and parallel: Both parallel combination and series combinations are in the middle of the battery pack, increasing the

Guide to Series and Parallel Configurations: 18650 and 21700 Batteries

Choosing the right configuration for lithium-ion battery cells is crucial for achieving optimal performance, safety, and longevity in your battery pack. This comprehensive guide will explore

How to Connect Lithium Batteries in Series and Parallel?

Aug 28, 2024 · Knowing how to connect these batteries in series, parallel, or even a combination, can help you tailor their performance to meet specific needs. In this article, we''ll explore the

Battery configurations (series and parallel) and

Jun 26, 2023 · Sometimes, battery packs are used in both configurations together to get the desired voltage and high capacity. This configuration is found in the

Battery Pack Calculator | Good Calculators

Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and maximum discharge

Battery Series and Parallel Connection Calculator

Jun 16, 2024 · Battery Series and Parallel Connection Calculator Battery Voltage (V): Battery Capacity (Ah): Number of Batteries: Calculate Linking multiple batteries either in series or

How to Connect Lithium Batteries in Series and

Jun 7, 2024 · We''ll explore the basics and provide detailed, step-by-step instructions on how to connect li-ion cells in series, parallel, and series-parallel

How to Correctly Connect Batteries in Series and

Apr 10, 2025 · Understanding how to properly connect batteries in series and parallel formula might seem straightforward, but by adhering to a few simple

Multi-fault diagnosis for series-connected lithium-ion battery pack

Oct 15, 2022 · We presented a novel multi-fault diagnosis method for a series-connected lithium-ion battery pack with a reconstruction-based contribution based on parallel PCA-KPCA.

6 FAQs about [Five parallel four series lithium battery pack]

Are series and parallel connection of lithium batteries safe?

The series and parallel connection of lithium batteries is a key technology to increase voltage and capacity, but it also contains safety risks. This article will analyze in detail the principles, methods and precautions of series and parallel connection of lithium batteries to help you avoid potential risks and build a battery system correctly.

Why is a lithium battery a series-parallel combination?

Due to the limited voltage and capacity of the single battery, in actual use, a series-parallel combination is required to obtain a higher voltage and ability to meet the existing power supply requirements of the equipment. Lithium batteries in series: the voltage is added, the capacity remains unchanged, and the internal resistance increases.

How to charge parallel lithium battery packs?

Specific principles must be followed when charging parallel lithium battery packs: Use a matching charger: The voltage must be suitable for the nominal voltage of the individual batteries. The current setting is reasonable: usually 0.2-0.5C of the total capacity after parallel connection.

What is lithium battery parallel connection?

Lithium battery parallel connection is to connect the positive poles of multiple batteries together, and the negative poles together, so that the total capacity can be increased while keeping the voltage unchanged.

What is a parallel battery connection?

Parallel Connection In a parallel connection, the batteries are linked side-by-side. This configuration keeps the voltage the same but increases the capacity. For instance, connecting two 3.7V 100mAh lithium cells in parallel will result in a total capacity of 200mAh while maintaining the voltage at 3.7V.

How many volts can a 3.7V lithium battery get?

For example, 4 pieces of 3.7V lithium batteries connected in series can get an output voltage of 14.8V, but the capacity remains unchanged. Series connection is the most common method to make the battery pack reach the required operating voltage. Series connection is the best choice when you need more voltage rather than more capacity.

Learn More

- Five parallel four series lithium battery pack

- 8 4v lithium battery pack in series

- Lomei square 17 series 60v lithium battery pack

- Lead-acid battery parallel lithium battery pack

- Pakistan 13 series lithium battery pack

- Lithium battery pack parallel power supply

- Lithium battery pack series discharge

- Montevideo 12v lithium battery pack

- Micronesia lithium battery pack factory

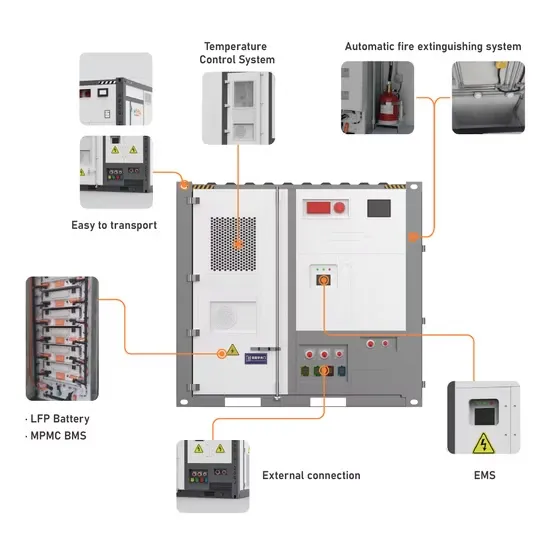

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.