Can I Mix Different LiFePO4 Batteries in a Pack?

Dec 19, 2021 · Currently popular rechargeable batteries are generally nickel-metal hydride batteries, lead-acid batteries and lithium-ion batteries. However,

Lead acid and lithium ion batteries in parallel

Here we look at the performance differences between lithium and lead acid batteries The most notable difference between lithium iron phosphate and lead acid is the fact that the lithium

Electrical Myths, Part 3: Mixing Batteries of Different

Jul 30, 2019 · With a lead acid battery bank, the internal resistances are limiting to a point that you don''t have to worry about arcing or your battery cables overheating when you connect them

DIY LiFePO4 Battery Pack: Step-by-Step Guide (2025 Update

Apr 18, 2025 · How to Build a LiFePO4 Battery Pack: DIY Guide with Expert Tips (2025) Why Build a LiFePO4 Battery Pack? LiFePO4 (Lithium Iron Phosphate) batteries dominate

Can lithium and lead-acid batteries be used in parallel?

Sep 15, 2021 · Summary: Lithium batteries and lead-acid batteries can not be used in parallel, but they can be used interchangeably. If you have any demands in batteries, please feel free to

Strings, Parallel Cells, and Parallel Strings

Feb 15, 2016 · Unlike lead-acid cells which are commonly assembled in parallel strings, lithium cells are very intolerant of over charge and over discharge. Since lithium cells must be

Lead-acid battery pack and lithium battery pack in parallel

Can you connect a lithium battery to a lead-acid battery? The customer can just plug them in. Suddenly you have the portability of the lithium battery and the inexpensive lead-acid batteries

Design and control of the hybrid lithium-ion/lead–acid battery

Oct 1, 2023 · The combination of these two types of batteries into a hybrid storage leads to a significant reduction of phenomena unfavorable for lead–acid battery and lower the cost of the

How To Wire Batteries In Series Vs Parallel

Jul 23, 2024 · Series wiring connects batteries in a line. The positive end of one battery connects to the negative end of the next. This setup raises the total

How to design battery packs, tutorial for Design Engineers

Apr 21, 2023 · With lead acid and lithium batteries parallel and even series + parallel packs are common. Series When used in series, the voltage is multiplied but the amp-hours stays the

batteries

Oct 27, 2023 · Each Lithium ion battery (LFP) cell is 3.2 V and 105Ah in capacity --> 3 in parallel is 315Ah and -->30 in series will 96V for the Lithium ion pack. And Lead Acid bank is 12V and

Parallel charging and discharging control of lead-acid battery

May 7, 2025 · The experimental results show that using the lead-acid battery pack returned from a DC system as the test object, after the application of the designed method, the rated voltage

Battery Packs In Series Or Parallel: Key Differences And

Mar 28, 2025 · For instance, connecting a lead-acid battery with a lithium-ion battery in a series configuration can cause the lithium battery to over-discharge, leading to damage or explosion.

Can lithium and lead-acid batteries be used in parallel?

Sep 15, 2021 · General lithium batteries used in series and parallel need to be paired with lithium battery cells. The criteria for pairing: lithium battery cell voltage difference ≤ 10mV, lithium

Combined Lithium and Lead acid battery system

Aug 31, 2024 · I have a question about the combination of a lithium Daron battery pack and lead acid batteries to run in parallel together. So this is my set up, I have a Sofar HYD-5000es

Active Cell Balancing of Lithium-ion Battery Pack Using Dual

Jan 1, 2021 · An auxiliary lead-acid battery is used to provide energy for cell balancing during discharging period instead of taking power from entire battery pack as typically used in P2C

Handbook On Lithium Battery Pack Design

Oct 30, 2023 · The History of Battery Market The use of lead-acid batteries (Pb/Ac) began in the nineteenth century. Because of low manufacturing costs, good performance and long life, the

Design and control of the hybrid lithium-ion/lead–acid battery

Oct 1, 2023 · This paper describes method of design and control of a hybrid battery built with lead–acid and lithium-ion batteries. In the proposed hybrid, bidirectional interleaved DC/DC

Can Lead Acid Battery Parallel with Lithium Battery

May 13, 2025 · No, you should not parallel a lead acid battery with a lithium battery. While it might seem like a cost-effective and practical solution, mixing these two types of batteries can lead

What Is The Difference Between Batteries In Parallel Vs Series?

Connecting batteries in parallel combines their capacity (Ah) at the same voltage, while series connections stack voltages while retaining individual capacity. For example, two 12V 100Ah

Can lead-acid batteries and lithium batteries be

Jun 7, 2023 · The reasons are as follows: 1. The discharge platform is different A single lithium battery is 3.7V, a single lead-acid battery is 2*2=4V, (a lead-acid

6 FAQs about [Lead-acid battery parallel lithium battery pack]

Are lithium ion and lead-acid batteries connected in parallel?

The different voltage profiles can lead to imbalances in a system if both types of batteries are connected in parallel or series. Lithium-ion batteries require a more controlled charging system to prevent overcharging or undercharging, while lead-acid batteries use simpler charging systems but are more sensitive to deep discharge cycles.

What happens if you mix lithium and lead-acid batteries?

Because of the inherent differences in their energy densities and voltage profiles, mixing lithium and lead-acid batteries can lead to poor system performance. The lithium battery might remain at a higher state of charge, while the lead-acid battery could be stressed due to excessive discharge.

Are lithium ion and lead-acid batteries the same?

Lithium-ion batteries provide a flat discharge curve, meaning they maintain a relatively constant voltage until near the end of the discharge cycle. In contrast, lead-acid batteries experience a gradual voltage drop as they discharge, which can lead to inconsistent performance if both types are used together.

How do I ensure battery compatibility between lithium and lead-acid batteries?

1. Use a Battery Management System (BMS) A key solution for addressing compatibility issues between lithium and lead-acid batteries is the use of a robust Battery Management System (BMS). A BMS can monitor the voltage, temperature, and charge levels of individual batteries, ensuring that each type operates within its safe range.

Can lithium & lead-acid batteries be electrically isolated?

If lithium and lead-acid batteries are part of the same system, they should be electrically isolated from one another. This can be done using a diode isolation system or an intelligent charge controller that ensures the batteries charge independently and prevents any backflow of current from one battery type to the other.

Can lead-acid batteries be used together?

In contrast, lead-acid batteries experience a gradual voltage drop as they discharge, which can lead to inconsistent performance if both types are used together. Mixing these two different technologies can cause several issues that impact performance, safety, and longevity of the overall power system. 1. Charging System Incompatibility

Learn More

- Lithium battery pack internal parallel connection

- 21700 two parallel lithium battery pack

- 60v lead-acid lithium battery pack

- Five parallel four series lithium battery pack

- 3 series and two parallel lithium battery pack

- Lithium battery pack parallel power supply

- Replacement of lithium battery pack

- Lithium iron phosphate power battery pack

- Assemble 15a lithium battery pack

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

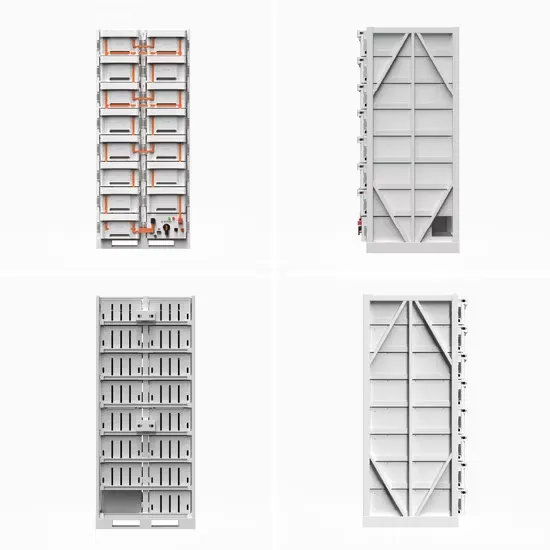

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.