Understanding High Voltage Lithium-Ion Battery

Mar 28, 2025 · Before investing in a high voltage lithium-ion battery, make sure you''re well-informed. This guide provides a comprehensive overview, covering

Tesla Batteries: What Kind of Battery Does My

Apr 12, 2025 · Let''s start with some Tesla battery chemistry trivia: Just so we''re clear, all Teslas, from the 2006 Roadster to the 2023 Model Y, use Lithium-Ion

Introduction: What Is a Lithium-Ion Battery Pack?

Whether you need a 7.4V, 11.1V, or 14.8V battery pack, understanding their structure, chemistry, and configuration is crucial. In this guide from A&S Power, we''ll explain the different types of Li

⚡ High Voltage Batteries: 7 Must-Know Facts & Fixes!

Mar 24, 2025 · Conclusion High voltage batteries are revolutionizing transportation and energy systems, but their complexity demands careful handling. Understanding their design, risks,

Modular High-Voltage Lithium-Ion Battery

5 days ago · Introducing the Proliance Intelligent Battery Series®, our latest high-voltage propulsion lithium-ion batteries. These battery systems are designed

LIHV: The Next Generation of High-Voltage Lithium Batteries

Jun 19, 2025 · Safer Operation – Lithium High-Voltage Batteries utilize advanced safety features that protect against overcharging, short-circuits, overheating during use as well as

HV Battery pack design considerations | Engibex

HV Battery pack design considerations Importance of Well-Thought-Out battery pack design The world is transitioning from Internal Combustion Engine (ICE) vehicles to Electric Vehicles

High voltage lithium battery – exploring it with

Jul 10, 2025 · This article provides a comprehensive overview of high voltage lithium battery, detailing their characteristics, development history, and

Lithium-ion Battery Insulation Resistance Testing

What is insulation resistance testing of lithium-ion batteries? Insulation resistance measurement serves as an important test for detecting defects on lithium-ion battery (LIB) cell production

Understanding HV Lithium Battery For Solar Storage

HV lithium batteries are high voltage batteries specifically designed for energy storage systems. Unlike traditional batteries, HV lithium batteries operate at higher voltages, typically ranging

What is an Electric Vehicle (EV) Traction Battery?

May 6, 2022 · An EV battery is also called a traction battery or traction battery pack. Unlike a standard 12 volt starting, lighting, and ignition (SLI) battery, an

What is a Lithium-ion Polymer High-Voltage

Nov 29, 2020 · A LiHv battery is a different type of Lithium-ion Polymer battery where "Hv" stands for "high voltage". It is more energy intensive than

The Future of High-Voltage Electric Vehicles: The

Oct 7, 2024 · But when a North American EV manufacturer designed a battery pack that contained several thousand cylindrical lithium-ion batteries and it

6 FAQs about [What is the use of high voltage lithium battery pack]

What is a high voltage battery pack?

2.Series-Connected High Voltage Battery Packs: These packs are formed by connecting multiple cells in series and are commonly used in solar energy storage, electric vehicles, and other applications where voltages can range from 12V up to 100V or more. This guide focuses on the former—high-voltage battery cells (LiHv cells).

What is a high voltage battery?

High voltage batteries are cells designed with a charging voltage higher than that of traditional batteries. While conventional rechargeable lithium-ion batteries typically have a full-charge voltage of 4.2V (with a nominal voltage around 3.7V or 3.6V), high voltage cells can reach full-charge voltages of 4.35V, 4.4V, or even 4.45V.

What is a high voltage lithium ion battery?

While conventional rechargeable lithium-ion batteries typically have a full-charge voltage of 4.2V (with a nominal voltage around 3.7V or 3.6V), high voltage cells can reach full-charge voltages of 4.35V, 4.4V, or even 4.45V. Their corresponding nominal voltages may be 3.8V, 3.85V, or 3.95V.

What are the different types of high voltage batteries?

Types of high voltage batteries Lithium-ion batteries are widely used due to their high energy density and lightweight design. They are commonly found in smartphones, laptops, and electric vehicles. These batteries can store a lot of energy in a compact size, which makes them ideal for portable electronics.

What are lithium ion batteries used for?

Lithium-ion batteries are widely used due to their high energy density and lightweight design. They are commonly found in smartphones, laptops, and electric vehicles. These batteries can store a lot of energy in a compact size, which makes them ideal for portable electronics. However, they can be expensive and may overheat if not properly managed.

Do high voltage batteries outperform low-voltage batteries?

High voltage batteries generally outperform low-voltage ones in applications requiring sustained power and energy efficiency. High voltage batteries are pivotal in transforming various sectors: Electric Vehicles (EVs): They provide the energy required for propulsion systems, supporting longer ranges and faster charging.

Learn More

- What is the use of 48v lithium battery pack

- Lithium battery pack medium and high voltage box

- Lithium battery pack 1000V high voltage charging and discharging

- What shock absorption is used for lithium battery pack

- What is the average lifespan of a lithium battery pack

- Lithium battery pack fast charging voltage

- What size inverter should I use for a 240A lithium battery

- What does lithium battery pack consistency mean

- What does lithium battery pack gram mean

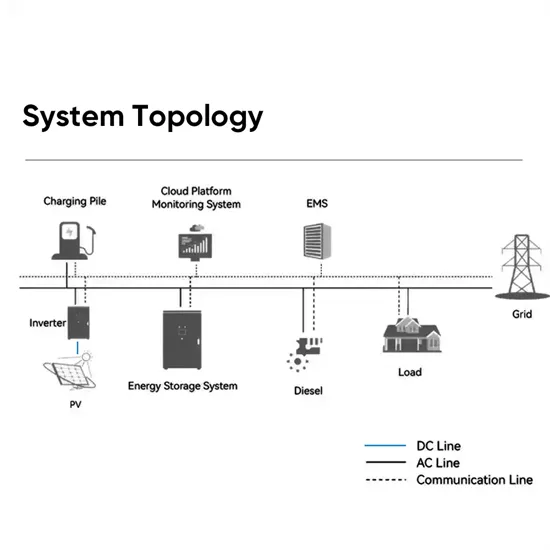

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.