What is the consistency of a battery?

Inconsistency between lithium cells can cause rapid capacity degradation and a reduction in battery life in lithium - battery packs. It is important to select cells with the same capacity,

What''s is lithium battery consistency and how to

May 10, 2021 · Lithium Battery Consistency And Sorting Method 1 nsistency of lithium batteries definition. At present, it refers to the convergence of a group

What Does Battery Consistency Mean?

Nov 29, 2024 · Battery consistency refers to the consistency of the initial performance indicators of the single cells used in the group, including capacity, electrical impedance, electrical

How does battery cosistency affect the lifespan

Dec 13, 2024 · Battery consistency plays a critical role in determining the lifespan and performance of a battery pack. Consistency refers to how uniform the

How are Lithium-ion Battery Packs Manufactured?

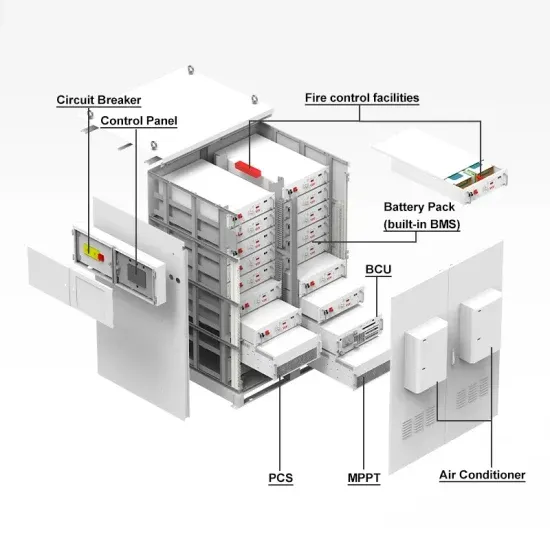

Lithium-ion battery packs are manufactured through a meticulous process that includes two key parts: the Battery Management System (BMS) and the battery pack assembly. The BMS is

Understanding Battery Labeling: What the

Apr 11, 2025 · Battery labels encode chemistry (e.g., "CR" for lithium), size (like "2032" indicating 20mm diameter x 3.2mm height), voltage, capacity, and

What does the consistency of lithium battery packs mean?

When the battery pack is assembled, the voltage difference of the single cell is an important factor affecting the consistency of each single cell at the end of the charge and discharge of the

A Copula-based battery pack consistency modeling method

Dec 15, 2019 · In this study, a Copula-based battery pack consistency modeling method is developed. The proposed method shows superiority compared with two existing methods,

Using EIS Technology For Consistency Screening

May 21, 2025 · By consistency screening before the batteries are shipped or assembled into modules and packs, the effective utilization of batteries can be

What does the consistency of lithium-ion batteries mean?

Sep 29, 2022 · The inconsistency of the lithium-ion battery pack or the discrete phenomenon of the battery pack refers to the voltage, charge, capacity, decay rate, internal resistance and its

Cell Consistency in Lithium Battery Packs Explained

Currently, lithium-ion battery consistency means bringing together important characteristic parameters of a group of batteries. It''s a relative concept, with no "most consistent," only "more

What Is Solar Lithium Battery Consistency?

Jul 28, 2025 · The consistency of solar lithium battery pack means that the parameters such as voltage, capacity, internal resistance, life, temperature effect, self-discharge

Study on battery pack consistency evolutions and equilibrium diagnosis

Dec 1, 2017 · The SOC consistency of battery pack can be employed as evaluation index representing the battery consistency level. As is known, the SOC-OCV function is a

Lithium-ion Battery PACK Tech Explained

The lithium-ion battery PACK, also known as a battery module, is an integral part of the lithium-ion battery production process. It involves the connection of multiple lithium-ion monomer cell

What does the consistency of lithium-ion batteries mean?

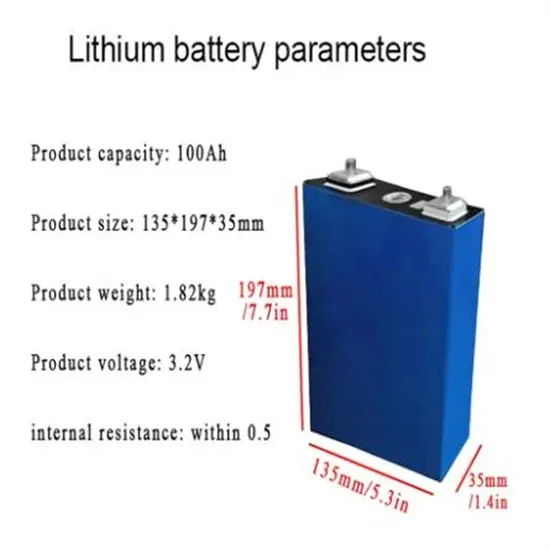

Sep 29, 2022 · Consistency of lithium-ion batteries refers to the consistency of initial performance indicators of single cells used in groups, including: capacity, impedance, electrical

What does the consistency of the lithium battery mean?!solar battery

The cell voltage and capacity of a single lithium battery are too low. Generally, multiple cells need to pass through the PACK to become a lithium battery pack, and then be applied to different

Understanding the voltage inconsistency features in lithium-ion battery

Apr 15, 2025 · Various methods have been employed for battery consistency screening, including the use of k-means clustering model [2], short-time pulse discharge and electrochemical

A Complete Guide to Understanding Battery Packs

Jul 24, 2024 · Battery packs come in many types, each suited to different needs and applications. Whether it''s for a smartphone, electric vehicle, or a portable

6 FAQs about [What does lithium battery pack consistency mean ]

Are lithium-ion batteries safe?

With the prevailing application of lithium-ion batteries, the durability and safety for battery packs receive more and more attentions from researchers and engineers since the improper usage of batteries will shorten the battery life , , , and even sometimes cause severe fire hazards , .

What is the inconsistency of battery capacity and internal resistance?

The inconsistency of the battery capacity, the internal resistance and the initial SOC of discharge is illustrated in Fig. 1. In this battery pack, the ratios of the range to mean value for the capacity, the internal resistance and the initial SOC of discharge are 16%, 21%, 34%, respectively.

What is the nominal capacity of a battery pack?

The nominal capacity of the battery pack is 105Ah, three cells with nominal capacity of 35 A h in parallel constitute a battery module, and 104 battery modules are then serially connected composed of the battery pack. The bus is off grid when parked at night, and the battery pack are not be charged when standing by.

How does temperature affect battery pack performance?

Ganesan et al. developed an electrochemical-thermal coupled model for a battery pack to analyze the battery pack performance under various rates and temperatures. An additional 5% capacity loss of the battery pack was obtained when there is a temperature difference of 15 °C among the cells .

What causes a difference between a battery and a cell?

Another occurs in usage. Inconsistency of battery original performance will cause difference in equivalent current rate, SOC usage range among cells. On the other side, battery pack thermal distribution is always nonuniform, causing temperature variations among cells.

What causes a difference in the initial performance of a battery?

One happens in the procedure of battery production , , , such as coating, ingredients and unevenness of impure contents of batteries which give rise to the difference in the battery initial performance like original capacity, resistance, coulombic efficiency and self-discharge rate.

Learn More

- What does lithium battery pack gram mean

- What does battery box pack design mean

- What is the price of lithium iron phosphate battery pack

- What is the built-in lithium battery pack

- What equipment is needed to make lithium battery pack

- What is the average lifespan of a lithium battery pack

- How many strings are there in a 12v lithium battery pack

- How much does a 80KWh lithium iron phosphate battery pack cost

- Q80c lithium battery pack

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.