What is a battery PACK? What are the factors to be

Sep 16, 2021 · 1, lithium battery pack structure PACK design involves many levels: for example, the mechanical structure design, to consider the strength, seismic, heat / heating, waterproof,

Pack Sizing and Requirements

Jul 4, 2025 · Initial sizing is around Electrical and Thermal. For a given cell can we get to a series and parallel configuration that meets the power demand? How fast do the cells heat up? What

How to design a smart battery junction box for advanced EV battery

Aug 16, 2023 · The main function of the battery management system (BMS) is to monitor cell voltage, battery pack voltage and battery pack current. In addition, given the high voltage

A Guide to Understanding Battery Specifications

Dec 18, 2008 · A battery is a device that converts chemical energy into electrical energy and vice versa. This summary provides an introduction to the terminology used to describe, classify,

Battery Design Explained: From Prototyping to Certification

Mar 20, 2025 · Learn how to design efficient, compliant battery packs for drones, robotics, medical devices, and e-mobility. Explore chemistries, BMS, certification, performance

Design approaches for Li-ion battery packs: A review

Dec 20, 2023 · Nowadays, battery design must be considered a multi-disciplinary activity focused on product sustainability in terms of environmental impacts and cost. The paper reviews the

What is a Battery Pack? Definition, Types, Applications, and

Dec 10, 2024 · A battery pack is a set of batteries or battery cells arranged in series or parallel to supply power. It stores energy for devices like electric vehicles.

Designing Intelligent Battery Junction Boxes for

Jun 14, 2023 · Designing Intelligent Battery Junction Boxes for Advanced EV Battery Management Systems As electric vehicles become more popular,

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · Designing a Lithium-Ion Battery Pack: A Comprehensive Guide In recent years, the demand for efficient and powerful energy storage solutions has surged, primarily driven by

Battery Manufacturer Tell You Everything About

May 29, 2024 · What exactly is a battery pack? What is its complete production line like? Find out with Ufine! Part 1. What is a battery pack? The lithium-ion

How to Design a Custom Battery Pack: A Step-by-Step Guide

This comprehensive guide walks engineers through the intricate process of designing a custom battery pack, offering a step-by-step approach with practical insights and technical

Strings, Parallel Cells, and Parallel Strings

Feb 15, 2016 · While it may seem that paralleling multiple strings would increase the overall reliability of a battery pack design, in reality, the opposite is usually true. Unlike lead-acid cells

What does PACK mean? What is battery PACK?

Jun 25, 2025 · They all have their own PACK structure design, PACK electronic design and PACK production workshops. They can carry out independent development and design according to

Understanding Lithim Battery Pack Enclosure Design for

May 7, 2025 · What''s a Lithium Battery Pack and Its Casing? A typical Li-ion battery pack consists of: • The Enclosure: Usually split into an upper cover and a lower case (or tray). • Li-ion Cells:

Battery Cell, Module, Pack, what`s the Difference?

Nov 20, 2024 · As electric cars become increasingly common in our daily lives, terms like "battery cell," "module," and "pack" pop up frequently. But what

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · In this blog post, we will delve into the key steps and considerations involved in designing a lithium-ion battery pack. Before diving into the design process, it''s crucial to

Cell to Pack: Key Design Considerations for CTP

Feb 1, 2025 · What is a CTP battery? A CTP battery stands for Cell-to-Pack ⇱. It''s a way of putting together battery packs that makes them lighter and more

6 FAQs about [What does battery box pack design mean ]

What is a battery pack?

A battery pack is more than just a collection of cells—it is a sophisticated system designed to store and deliver energy safely and efficiently. Below, we break down the key components of a battery pack and their functions. A battery pack consists of several interconnected parts, each playing a vital role in energy storage and power delivery:

What are the parts of a battery pack?

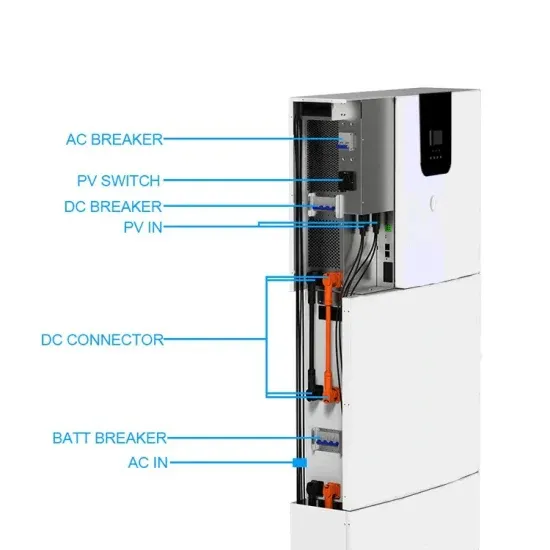

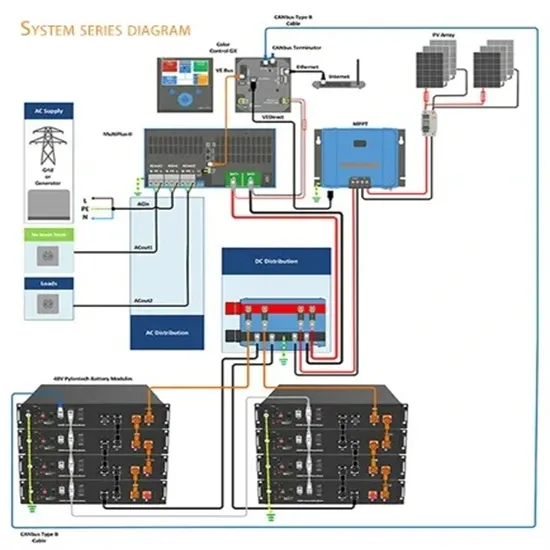

A battery pack consists of several interconnected parts, each playing a vital role in energy storage and power delivery: Battery Cells – The core energy storage units. Battery Management System (BMS) – Regulates voltage, temperature, and safety. Cooling System – Prevents overheating and maintains efficiency.

What are the basic components of a lithium-ion battery pack?

Before diving into the design process, it's crucial to understand the fundamental components of a lithium-ion battery pack: Cells: The basic building blocks of a battery pack. Lithium-ion cells come in various shapes (cylindrical, prismatic, pouch) and chemistries (e.g., NMC, LFP).

How can battery packaging design improve battery safety?

A robust and strategic battery packaging design should also address these issues, including thermal runaway, vibration isolation, and crash safety at the cell and pack level. Therefore, battery safety needs to be evaluated using a multi-disciplinary approach.

What makes a good battery pack?

Battery pack design is crucial for electric vehicles (EVs) and energy storage systems. A well-designed battery pack ensures efficiency, safety, and longevity. But what makes a great battery pack? It’s more than just batteries. It includes cooling systems, management electronics, and structural integrity.

How do you design a battery pack?

Designing an efficient and reliable battery pack involves multiple engineering considerations. The following key factors influence performance, safety, and durability. Voltage (V): Total voltage increases when cells are connected in series. Capacity (Ah): Total capacity increases when cells are connected in parallel.

Learn More

- What does lithium battery pack gram mean

- What brand of aluminum is used in the power battery pack box

- What does lithium battery pack consistency mean

- Lithium battery pack capacity design

- What is the use of 48v lithium battery pack

- Battery Pack product design

- What does lithium battery upgrade BMS mean

- What is the use of high voltage lithium battery pack

- What is the capacity of the battery pack of the communication base station

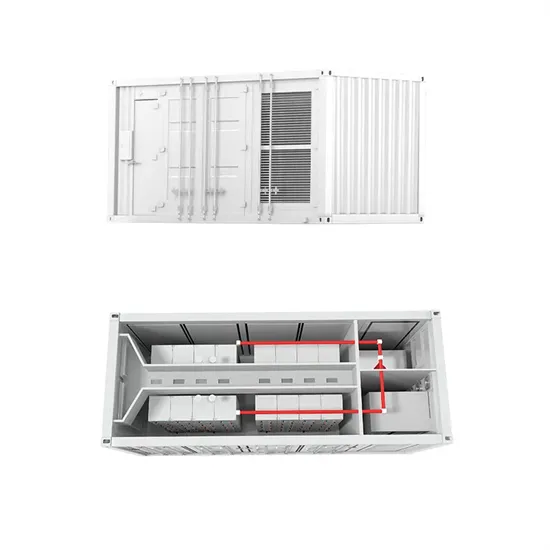

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.