Aluminum Used in Electric Car Battery and Engine

Aluminum Used in Electric Car Battery and Engine The power battery system (battery pack) is the power source of the whole new energy vehicle and one of the most critical components of

What Is a Power Pack and How Does It Work?

May 24, 2025 · Power packs operate by efficiently storing and converting energy for immediate use. Battery cells accumulate and retain electrical energy, derived from various sources like

An overview and prospective on Al and Al-ion battery technologies

Jan 1, 2021 · Aluminum batteries are considered compelling electrochemical energy storage systems because of the natural abundance of aluminum, the high charge storage capacity of

Aluminum Battery Enclosure Design

Feb 11, 2021 · Aluminum as sheet and extruded profiles is the preferred material for BEV body structure, closures and battery enclosures. Aluminum battery enclosures or other platform

The shell material of the battery shell

The battery case is an important part of the battery, and its main functions include protecting the internal components, improving the battery safety and extending the service life. The choice of

The difference between steel-shell, aluminum

Nov 6, 2020 · The shell materials used in lithium batteries on the market can be roughly divided into three types: steel shell, aluminum shell and pouch cell

What aluminum alloys are used in electric vehicle battery

Sep 20, 2023 · The battery boxes material is a high-purity aluminum alloy product formed through processes such as hot rolling, cold rolling, annealing, stretch bending and straightening, and

A complete guide to soft pack battery assembly,

May 5, 2025 · 1. Soft-pack batteries Soft-pack batteries use aluminum-plastic film to replace traditional steel/aluminum shells. With ultra-high energy density

Soft-Pack Batteries and Aluminum-Shell Batteries

Dec 13, 2024 · The degree of automation in the manufacturing of aluminum shell batteries is higher than that of lithium battery pack soft-pack batteries. Therefore, to a certain extent, the

Optimization Analysis of Power Battery Pack Box Structure

Mar 10, 2023 · The power battery is the only source of power for battery electric vehicles, and the safety of the battery pack box structure provides an important guarantee for the safe driving of

Battery Cell, Module, Pack, what`s the Difference?

Nov 20, 2024 · As electric cars become increasingly common in our daily lives, terms like "battery cell," "module," and "pack" pop up frequently. But what

Battery Pack Essentials: Understanding The Basics

Dec 31, 2023 · What is a Battery Pack? A battery pack is a portable energy storage device that consists of multiple individual batteries or cells connected together to provide electrical power.

Material selection of EV battery pack housing

The EV power battery pack shell adopts aluminum alloy material, which has the characteristics of easy processing and forming, high temperature corrosion resistance, good heat transfer and

6 FAQs about [What brand of aluminum is used in the power battery pack box]

Which aluminum alloy is used in power batteries?

Aluminum alloy is a commonly used material for power batteries, and there is an urgent need to focus on research, development, and upgrading of products and alloy materials. At present, the conventional aluminum alloys used in power batteries mainly include 1-series, 3-series, 5-series, and 6-series.

What material is used in power battery aluminum trays?

Chalco's production of power battery aluminum trays mostly uses 6-series 6061 aluminum plate as the raw material for battery aluminum trays, which can meet the characteristics of high precision, corrosion resistance, high temperature resistance, and impact resistance to protect the battery core.

What materials are used in battery pack housing?

With the development of energy saving, environmental protection and lightweight of the car, a variety of lightweight material options such as glass fiber reinforced composite materials, SMC sheet materials, and carbon fiber reinforced composite materials have also appeared in battery pack housing materials.

Why is aluminium a good battery material?

Aluminium’s unique properties make it the go-to material for battery applications. With its high conductivity, the battery’s internal and external electrical resistance can be kept low, allowing high charging speeds. Paired with its low specific weight, it is not by chance that aluminium plays a vital role in state-of-the-art lithium-ion batteries.

What material is used for a battery enclosure?

The majority of long-range BEVs in production use aluminum as the main material for the battery enclosure. (Constellium) Mass reduction is the main driver behind aluminum battery enclosures, but thermal requirements prove challenging for the lightweight material.

What are the advantages of aluminum alloy shell EV battery pack?

In addition, the aluminum alloy shell EV battery pack has the following four advantages. 1.long lasting. The simulated aging test of aluminum alloy shell shows that its service life is more than 20 years, which far exceeds that of traditional materials such as metal. 2. Flame retardant, smokeless and non-toxic.

Learn More

- What does battery box pack design mean

- Which brand of power lithium battery pack is good

- What type of battery is used for energy storage power supply

- What shock absorption is used for lithium battery pack

- What brand of lithium battery pack is good in Syria

- Lithium battery pack for power supply

- Photovoltaic power station energy storage battery brand

- Ele Power Lithium Battery Pack

- Albania Power Lithium Battery Pack

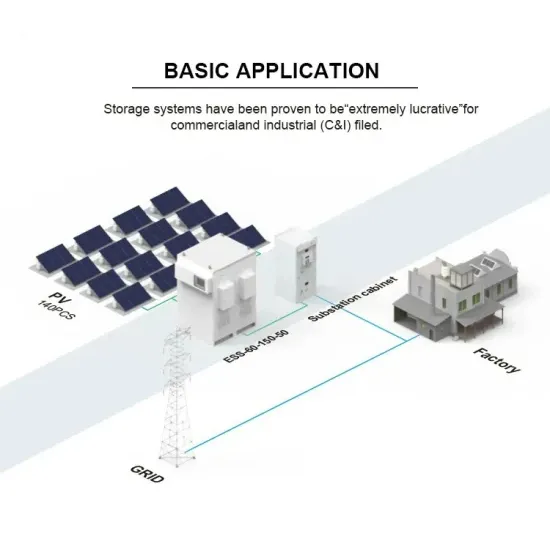

Industrial & Commercial Energy Storage Market Growth

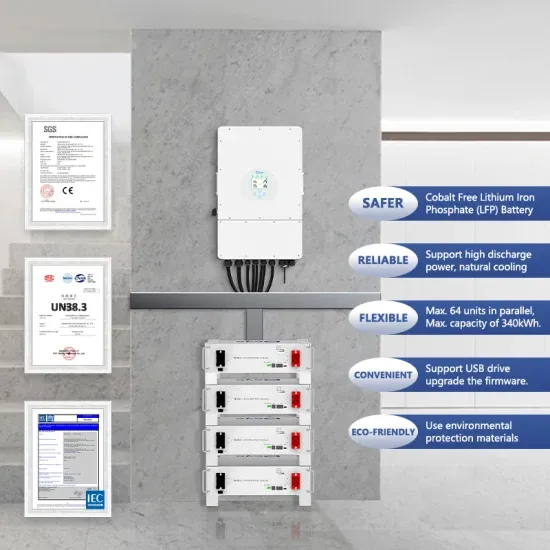

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

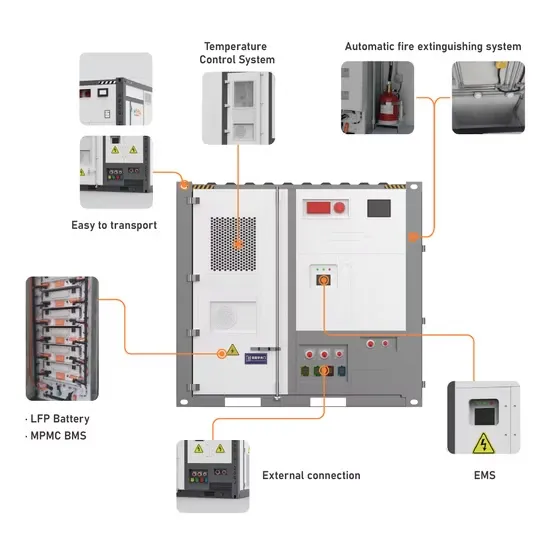

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.