BMS for Lithium-Ion Batteries: The Essential Guide to Battery

Jul 22, 2025 · For lithium-ion batteries specifically, the BMS serves as a critical safety component that prevents dangerous conditions while optimizing battery performance. The BMS

The Role of the BMS in Modern Lithium Batteries – Why It

Jul 23, 2025 · Modern lithium batteries are no longer simple storage units; they are intelligent energy systems designed to deliver safe, efficient, and lasting performance. At the heart of

How Long Does It Take to Charge a 72Ah Lithium Battery

Aug 2, 2025 · Quality lithium batteries with functioning BMS will typically disconnect before dangerous overcharging occurs. However, repeated overcharging causes electrolyte

Best Lithium Golf Cart Batteries: Top 5 Picks

6 days ago · Upgrade your golf cart experience with the OGRPHY 48 Volt Lithium Battery. This powerful battery offers a massive 5.12kWh of energy, giving you the power to play more holes

Do I Need a BMS for Lithium-Ion Batteries? Benefits and

Apr 15, 2025 · A Battery Management System (BMS) is crucial for lithium-ion batteries. It ensures safe operation by preventing overcharging and excessive discharging. The BMS provides

BMS for Lithium-Ion Battery: Essential Guide

Aug 14, 2025 · BMS stands for Battery Management System. It is a sophisticated electronic system that manages rechargeable batteries, such as lithium-ion batteries, by diligently

What Is a Lithium Battery Management System and How Does

Apr 23, 2025 · A Lithium Battery Management System (BMS) monitors voltage, temperature, and current to prevent overcharging, overheating, and short circuits. By balancing cell voltages and

How Does A Battery Management System Work In Lithium

Aug 14, 2025 · A Battery Management System (BMS) monitors, protects, and optimizes lithium-ion battery performance by tracking voltage, temperature, and current. It balances cell charges

Battery Management Systems (BMS) in Lithium Leisure Batteries

Mar 2, 2023 · The Battery Management System, otherwise known as a BMS, is the ''intelligent'' component responsible for the management and control of your lithium leisure battery.

What Does BMS (Battery Management System) Mean?

4 days ago · Why is BMS a common term in lithium battery specs? You''ll see "BMS included" splashed across spec sheets like some badge of honor. And for good reason—if a lithium

BMS module: What it is and why it is key in lithium batteries

Feb 14, 2025 · The BMS is an essential system for managing and protecting lithium batteries. Prevents overloads, overheating and battery failures. There are different types of BMS

What Does BMS Mean? A Comprehensive Guide – Renogy US

Conclusion What does BMS mean? Is this what you''re looking for? Well, it is a battery management system that ensures the safe, reliable, and long-lasting performance of battery

What Does A Battery Management System Do?

Jun 5, 2025 · A Battery Management System (BMS) is an electronic controller that monitors and manages lithium-ion battery performance. It ensures safety by preventing overcharge, over

A Beginner''s Guide to Battery Management System

Apr 1, 2025 · Below is a simple introduction to common terms related to Battery Management Systems (BMS), designed to help beginners understand the basics. This guide covers "1S,"

What is a BMS, and Why Do I Need One? –

Feb 11, 2025 · A Battery Management System (BMS) is an electronic system built into a lithium battery to monitor, regulate, and protect it from damage. Think of

What Is a BMS in Batteries? Definition, Functions,

Jun 10, 2025 · A Battery Management System (BMS) is the intelligent controller that ensures batteries are used safely, efficiently, and reliably. Whether you''re

How does lithium battery BMS determine the

May 1, 2025 · This article will explore the functions, working principles, application areas, future development trends, and challenges of lithium battery BMS in

What Is A BMS Battery Management System?

A Battery Management System (BMS) is an electronic control unit that monitors and manages rechargeable battery packs. It ensures safety by preventing overcharging, over-discharging,

Understanding BMS in Lithium Batteries: Importance and

Feb 9, 2025 · In summary, a Battery Management System (BMS) is an integral component of lithium battery technology, ensuring their safe, efficient, and reliable operation. With functions

Do I Need a BMS for Lithium-Ion Batteries? Benefits and

Apr 15, 2025 · A Battery Management System (BMS) protects lithium-ion batteries from overcharging by monitoring their voltage and controlling the charge process. The BMS

Understanding the Role of the BMS in Modern Lithium Batteries

Aug 19, 2025 · What Is a BMS? The Battery Management System is an electronic circuit board built into or attached to a lithium battery pack. Its primary function is to monitor, manage, and

What Does BMS Mean in Lithium Batteries?

Dec 19, 2024 · In short, BMS ensures that your battery works efficiently, safely, and lasts as long as possible. The BMS is responsible for several crucial functions that protect and optimize

6 FAQs about [What does lithium battery upgrade BMS mean ]

Why do lithium batteries need a BMS?

Overcharging or discharging a lithium-ion battery can shorten its life and even cause safety hazards. A BMS prevents this by automatically disconnecting the battery from the charger or load when it reaches unsafe levels, safeguarding the battery and preventing potential damage.

What is lithium battery management system (BMS)?

To ensure the safe, stable, and efficient operation of battery packs, the Battery Management System (BMS) was developed, becoming an indispensable core component in lithium battery systems. This article will explore the functions, working principles, application areas, future development trends, and challenges of lithium battery BMS in depth.

What does BMS mean in a battery?

At its core, BMS stands for Battery Management System. It's an essential component for lithium-ion batteries, which are commonly used in electric vehicles (EVs), energy storage systems (ESS), and other devices that require rechargeable batteries.

Why do you need a battery management system (BMS)?

As a result, a BMS significantly enhances the overall performance of the battery. Efficient charging and discharging cycles are crucial for getting the most out of your lithium-ion battery. A BMS ensures that these processes are handled smoothly and efficiently, optimizing battery performance and energy efficiency.

Are lithium-ion batteries safe to operate without BMS protection?

A: Operating lithium-ion batteries without proper BMS protection is extremely dangerous and not recommended. While basic protection circuits exist, they lack the comprehensive monitoring and management capabilities needed for safe operation.

What is a battery based monitoring system (BMS)?

BMS communicates with external devices (such as vehicle control units, charging stations, and monitoring systems) through communication interfaces such as CAN bus, LIN bus, or Ethernet, enabling real-time data exchange and system integration. Lithium battery BMS operates based on real-time monitoring and intelligent algorithm processing.

Learn More

- What does lithium battery pack gram mean

- What does lithium battery pack consistency mean

- What is the built-in lithium battery pack

- Kigali lithium battery bms manufacturer

- Timor-Leste lithium battery bms manufacturer

- Bogota lithium battery bms module

- Georgia lithium battery bms system

- Battery site energy scanning site what does it mean

- Nigeria Lagos energy storage lithium battery bms wholesale

Industrial & Commercial Energy Storage Market Growth

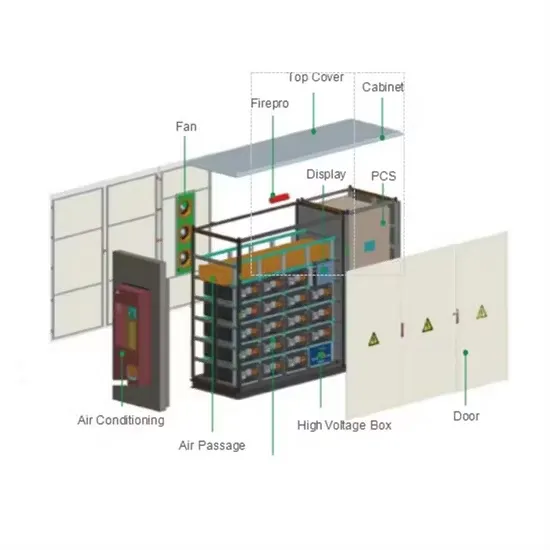

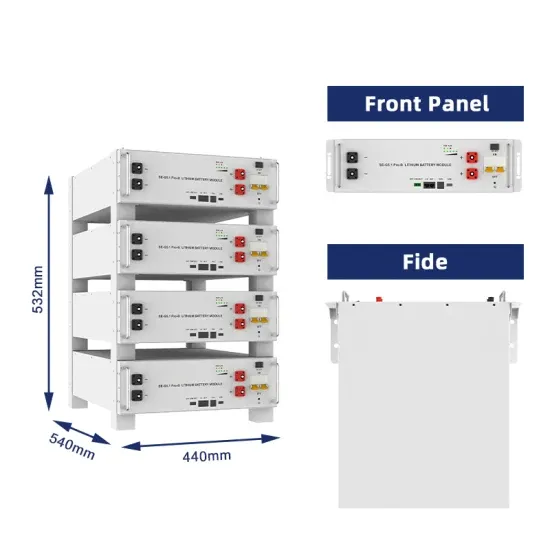

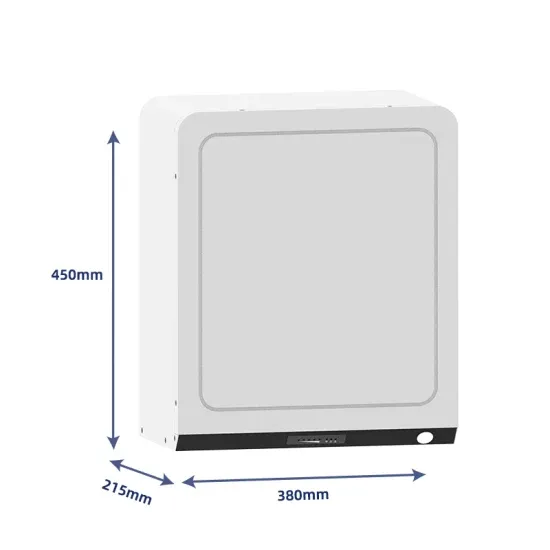

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.