The Calculation of Electric Motor and Lithium Battery

Mar 18, 2025 · An electric-vehicle battery is used to power the electric motors of a electric vehicle. These batteries are rechargeable batteries and they are typically lithium-ion batteries. These

Battery Pack Design of Cylindrical Lithium-Ion Cells and

Sep 12, 2022 · ly. This research considers two related topics. The first is the design of a battery submodule made up of cylindrical lithium cells. The objective of this design is to improve its

INSTRUCTION MANUAL: BATTERY PACK DESIGN, BUILD

Apr 29, 2021 · Comparing Table 2 and Table 6 reveals that battery packs designed as per recommendations, individual cells will each store or drain less than the OEM rated capacity as

The Handbook of Lithium-Ion Battery Pack Design:

May 16, 2024 · His first book, The Hand-book of Lithium-Ion Battery Pack Design, was published in 2015, and his second book, Lithium-Ion Chemistries: A Primer, was published in 2019.

Cell Form Factors & Lithium Battery Sizes in Pack

Apr 9, 2024 · Explore the various types of lithium battery sizes, common cell forms, & their significance in lithium-ion battery pack design with Acculon Energy.

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Cell Form Factors & Lithium Battery Sizes in Pack

Apr 9, 2024 · Large cell size and effective cell-to-pack packaging simplify pack design and manufacturing, driving costs down, but cooling and safety must be

Understanding Lithium Battery Configurations:

Apr 18, 2025 · Discover the different types of lithium battery cells, their configurations, and practical applications to create efficient and reliable energy

Design approaches for Li-ion battery packs: A review

Dec 20, 2023 · Liquid-cooled battery pack design is increasingly requiring a design study that integrates energy consumption and efficiency, without omitting an assessment of weight and

Lithium Battery Pack Design and Performance Optimization

Apr 18, 2025 · A lithium battery pack is an assembly of individual lithium-ion cells connected in series or parallel to provide the desired voltage and capacity. The configuration of these cells

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · Designing a Lithium-Ion Battery Pack: A Comprehensive Guide In recent years, the demand for efficient and powerful energy storage solutions has surged, primarily driven by

The Handbook of Lithium-Ion

Aug 16, 2025 · The Handbook of Lithium-Ion Battery Pack Design This page intentionally left blank The Handbook of Lithium-Ion Battery Pack Design Chemistry, Components, Types and

Design approaches for Li-ion battery packs: A review

Dec 20, 2023 · Nowadays, battery design must be considered a multi-disciplinary activity focused on product sustainability in terms of environmental impacts and cost. The paper reviews the

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · In this blog post, we will delve into the key steps and considerations involved in designing a lithium-ion battery pack. Before diving into the design process, it''s crucial to

Battery Pack Design of Cylindrical Lithium-Ion Cells and

Sep 12, 2022 · Battery Pack Design of Cylindrical Lithium-Ion Cells and Modelling of Prismatic Lithium-Ion Battery Based on Characterization Tests By Ruiwen Chen, B.Eng. & Co-op.

Design and Analysis of Large Lithium-Ion Battery Systems

May 4, 2021 · This new resource provides you with an introduction to battery design and test considerations for large-scale automotive, aerospace, and grid applications. It details the

Lithium Battery Capacity Calculator

Oct 28, 2024 · Lithium Battery Design and Disadvantages What is the biggest disadvantage of a lithium-ion battery? The primary disadvantages of lithium-ion batteries include cost, sensitivity

Design for Assembly and Disassembly of Battery Packs

Aug 23, 2019 · A key factor for succeeding in installation as well as recycling of battery packs is the ability to modularise the battery pack design to enable high level of configurability needed

6 FAQs about [Lithium battery pack capacity design]

How do I calculate the capacity of a lithium-ion battery pack?

To calculate the capacity of a lithium-ion battery pack, follow these steps: Determine the Capacity of Individual Cells: Each 18650 cell has a specific capacity, usually between 2,500mAh (2.5Ah) and 3,500mAh (3.5Ah). Identify the Parallel Configuration: Count the number of cells connected in parallel.

What are the basic components of a lithium-ion battery pack?

Before diving into the design process, it's crucial to understand the fundamental components of a lithium-ion battery pack: Cells: The basic building blocks of a battery pack. Lithium-ion cells come in various shapes (cylindrical, prismatic, pouch) and chemistries (e.g., NMC, LFP).

What are the components of a battery pack?

Cells: The basic building blocks of a battery pack. Lithium-ion cells come in various shapes (cylindrical, prismatic, pouch) and chemistries (e.g., NMC, LFP). Modules: Groups of cells assembled together in a specific configuration (series, parallel, or a combination) to achieve the desired voltage and capacity.

How safe is a lithium-ion battery pack?

Safety is paramount in lithium-ion battery pack design. Here are some key safety considerations: Overcharge Protection: Implement safeguards to prevent overcharging, which can lead to thermal runaway and fire. Over-Discharge Protection: Prevent cells from discharging below their safe voltage limit to avoid permanent damage.

What is the energy density of a lithium-ion battery module?

ergy density of a lithium-ion battery module can reach 150-200Wh/kg, which is higher compared t the batteries of other chemistries. Therefore, the lithium-ion battery has become the mainstream in the field of electric vehicles. The objective in this research is to develop a 48 V battery pack with a high energy den

How has lithium-ion battery technology changed the energy storage landscape?

The evolution of lithium-ion battery technology has revolutionized the energy storage landscape. As the demand for efficient and sustainable energy solutions grows, understanding the intricacies of battery pack architecture becomes paramount.

Learn More

- Lithium battery pack single cell capacity error

- 4V large capacity lithium battery pack accessories

- Lithium battery pack has low capacity

- Expand the capacity of lithium battery pack

- Bucharest large capacity lithium battery pack

- Which lithium battery pack is cheaper in New York USA

- 60V 50A lithium battery pack

- Assemble 15a lithium battery pack

- Lithium battery pack judgment

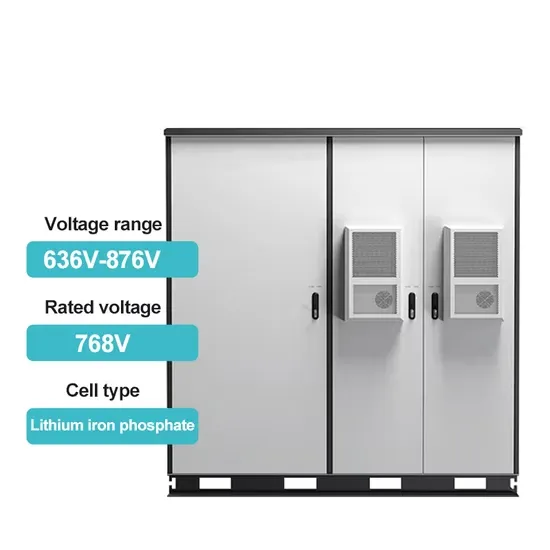

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

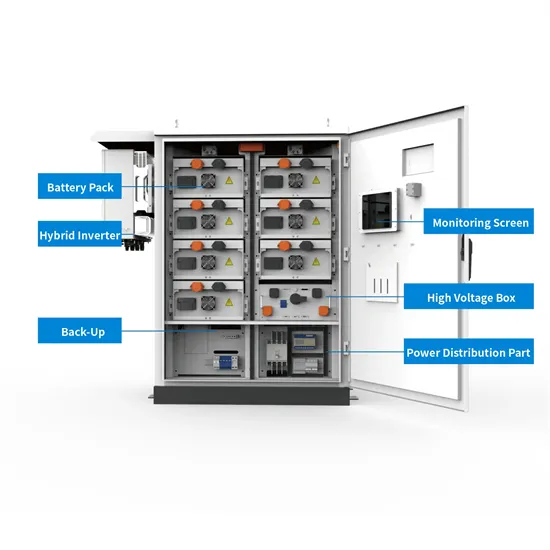

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.