State of charge estimation with representative cells-based

Jun 15, 2025 · However, applying models designed for single cells directly to battery packs can be problematic because of variations in electrochemical parameters such as capacity and internal

Capacity evaluation and degradation analysis of lithium-ion battery

Aug 15, 2023 · Accurately calculating the capacity of battery packs is of great significance to battery fault diagnosis, health evaluation, residual value assessment

A LiFePO4 battery pack capacity estimation approach considering in

Mar 15, 2015 · Research and literature about single cell capacity prediction are still the most concerned topics. Lu et al. [2] summarized the basic algorithms used for the battery cell state

Capacity Estimation of Serial Lithium-ion Battery Pack Using

Nov 27, 2019 · The existence of the consistency degradation of the battery pack hinders the accurate estimation of pack capacity and cell capacity in the battery pack. The paper focuses

State-of-health monitoring of lithium-ion battery modules and packs

Oct 15, 2016 · Incremental capacity analysis (ICA) is a widely used technique for lithium-ion battery state-of-health (SOH) evaluation. The effectiveness and robustness of ICA for single

Influence of the connection topology on the performance of lithium

Sep 1, 2021 · In summary, the impact of parameter variations on the performance of battery packs with different topologies was widely published, from series to parallel, through statistical

Lithium-ion battery pack equalization based on charging

Feb 1, 2020 · Lithium-ion battery pack capacity directly determines the driving range and dynamic ability of electric vehicles (EVs). However, inconsistency issues occur and decrease the pack

Quantitative short circuit identification for single lithium-ion cell

Jan 1, 2022 · However, for the application scenarios of one single cell, the existing methods cannot determine short circuit due to the lack of healthy batteries as a reference. Therefore, a

Online Equalization Strategy for Lithium-Ion Battery Packs

Jan 28, 2025 · After a single active equalization of the battery pack based on the SOC, the battery pack capacity is equal to the capacity of the cell 1 and the battery pack SOC increases.

Determination of the battery pack capacity considering the estimation

Sep 1, 2016 · Lithium-ion batteries have been widely used as the power source of electric vehicles (EVs) in recent years [1], [2]. Generally, the battery system for EVs is composed of numerous

Active equalization for lithium-ion battery pack via data

Oct 10, 2023 · In the text of global warming and shortage of fossil fuels, electric vehicles (EVs) have been seen as a promising alternative for conventional vehicles and become extremely

Battery Pack Calculator | Good Calculators

Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and maximum discharge

Understanding aging mechanisms in lithium-ion battery packs: From cell

Mar 15, 2015 · Battery cell capacity loss is extensively studied so as to extend battery life in varied applications from portable consumer electronics to energy sto

A novel li-ion battery pack modeling considerging single cell

Oct 5, 2017 · In this paper, a novel modeling method of battery pack for an optimal design and effective managements of battery is suggested. The proposed modeling method usi

Capacity evaluation and degradation analysis of lithium-ion battery

Aug 15, 2023 · Taking the mileage and service life as variables, two degradation models of battery capacity are established with mean absolute errors equal to 3.138 Ah and 3.137 Ah. According

A new method to perform lithium-ion battery pack fault

Aug 30, 2023 · In addition, the single cell capacity and energy data were scaled by a factor of 8 and compared with the supercell data. The difference between the cell and supercell level

Active cell equalization for lithium-ion battery packs in

Jul 1, 2025 · The cell equalization is the crucial part of BMS to manage battery packs, particularly those comprising multiple cells connected in series and/or parallel, such as Lithium-ion (Li-ion)

State of health estimation and error reduction method for

Feb 15, 2025 · The BMS can manage configurations ranging from a single lithium-ion battery cell to multiple cells connected in series and parallel, as well as modules composed of these

Optimal fast charging strategy for series-parallel configured lithium

Jan 1, 2025 · Despite the extensive research dedicated to optimizing the charging process for single cells, control strategies for packs remain unexplored. This paper focuses on the battery

Detection and isolation of faults in a lithium-ion battery pack

Jun 15, 2024 · This paper presents a method of detecting a single occurrence of various common faults in a Lithium-ion battery pack and isolating the fault to the faulty PCM, its connecting

Lithium battery pack capacity error

Are lithium-ion battery faults dangerous? However, various faults in a lithium-ion battery system (LIBS) can potentially cause performance degradation and severe safety issues. Developing

6 FAQs about [Lithium battery pack single cell capacity error]

Why does a series parallel battery pack deteriorate?

Through the above analysis, the capacity of every single cell in the series–parallel battery pack is different, which causes the single cell to overcharge and overdischarge during the charge and discharge cycle, accelerating the aging of the single cell and causing the battery pack’s parameter difference to deteriorate.

Why is the SOC difference of a parallel-connected battery pack not stable?

The individual cells’ SOC difference of each branch of the parallel-connected battery pack is not stable, and variations in standing and drastic working conditions will result in the disappearance of individual cells’ SOC difference, which has little significance. The capacity difference of the individual cells is frequently not a single variable.

What determines a battery pack's performance?

When there is a capacity difference between individual cells, the battery pack’s performance is determined by the individual cells with the smallest capacity. When there is a polarization difference between individual cells, the battery pack’s performance is determined by the single cell with the largest polarization degree. 3.1.2.

How important is terminal voltage in a battery pack?

In addition to individual cells’ capacity utilization and individual cells’ energy utilization, individual cells’ terminal voltage is also an important indicator of the battery pack’s performance. The operating condition is set to discharge the single cell at a 1C rate and reaches the single cell’s discharge cutoff voltage.

How to evaluate battery pack performance based on ohmic resistance difference?

The capacity utilization and energy utilization are used to evaluate the battery pack’s performance based on the above derivation results. When there is an Ohmic resistance difference between the individual cells, the individual cells with the highest Ohmic resistance limit the series-connected battery pack’s performance.

How a battery pack model is based on cell-to-cell variation?

Furthermore, cell-to-cell variation and packaging elements are taken into consideration in the process of battery pack modeling for the model accuracy. The proposed modeling method of battery pack is verified with the help of simulation and experimental results based on Li-ion battery along with battery charger and discharger.

Learn More

- Small cylindrical single cell lithium battery

- 1850 lithium battery pack capacity 20ah

- Ljubljana single lithium battery pack

- Lithium battery pack capacity design

- Morocco Casablanca large single lithium battery pack

- Bucharest large capacity lithium battery pack

- Expand the capacity of lithium battery pack

- 150a large single lithium battery pack

- 60V 50A lithium battery pack

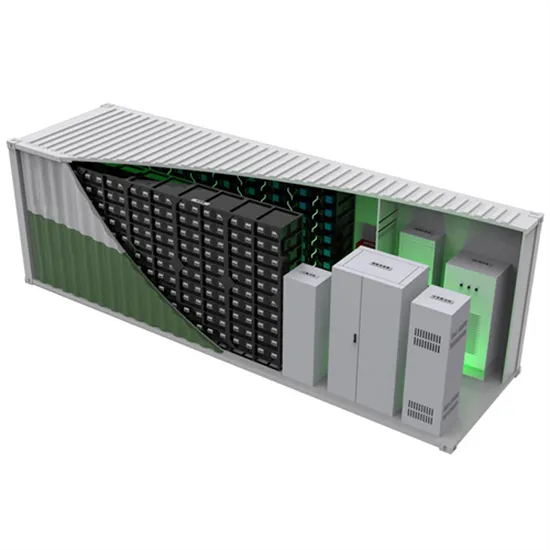

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.