Sunway BESS 400v 832v Battery Pack Container 1000kw

Supplier highlights: This supplier mainly exports to Thailand, Finland, and Germany, offers full customization, design customization, and sample customization, holds product certifications

Li-ion Batteries Safe Discharge Guide for Storage and Disposal

Jul 20, 2025 · Safely discharge Li-ion batteries for storage or disposal with step-by-step guidance on voltage limits, personal protection, and proper handling to prevent hazards.

Battery Pack Calculator | Good Calculators

Battery Pack Calculator Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · Consider factors such as energy capacity, voltage, current, cycle life, and space constraints. Select Cells: Choose the appropriate type and chemistry of cells based on your

Understanding Battery Pack Technology: Key Components,

Mar 14, 2025 · Discover the essential aspects of battery pack technology, including key components such as cells, BMS, structural components, thermal management, production

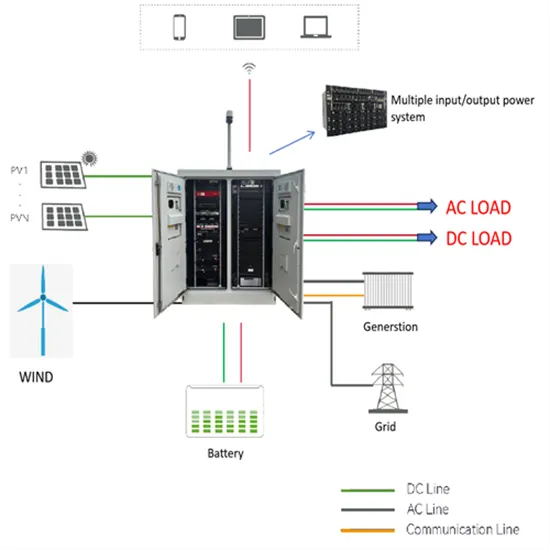

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

Understanding Lithium Battery Pack Enclosure Design for

May 7, 2025 · Let''s dive into the essentials of designing these crucial battery enclosures. What''s a Lithium Battery Pack and Its Casing? A typical Li-ion battery pack consists of: • The Enclosure:

The Complete Guide to Lithium-Ion Battery

Nov 14, 2023 · The Importance of Voltage in Lithium-Ion Batteries Now, let''s talk about voltage. In simple terms, voltage is the electrical pressure that pushes

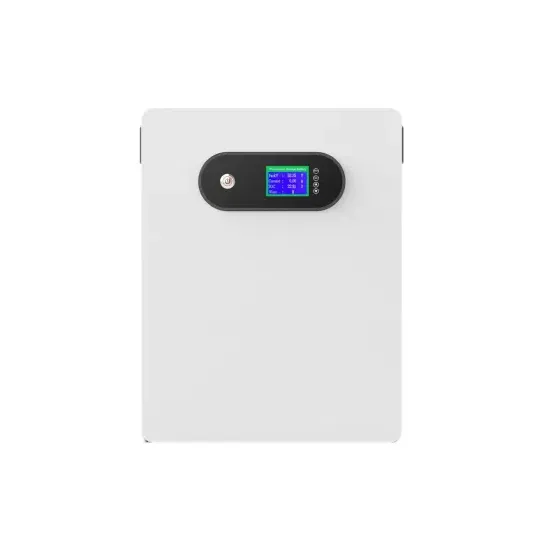

Energy storage container for storing the solar

4 days ago · The energy storage system is essentially a straightforward plug-and-play system which consists of a lithium LiFePO4 battery pack, a lithium solar

How Does A Container Battery Work?

May 26, 2025 · Container batteries are large-scale energy storage systems housed in standardized shipping containers. They integrate lithium-ion or flow battery cells, battery

HIGH VOLTAGE CONTAINERIZED LITHIUM PHOSPHATE

Nov 22, 2021 · High voltage containerized lithium battery storage system is composed of high quality lithium iron phosphate core (series-parallel connection), advanced BMS management

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Discover how lithium-ion battery packs are made—sorting, welding, assembly, BMS integration, and testing—to deliver reliable power for EVs,

Introduction: What Is a Lithium-Ion Battery Pack?

Jul 4, 2025 · Learn the differences between 18650, 21700, and custom lithium-ion battery packs. Understand voltages like 11.1V and 14.8V, and how to choose the right Li-ion battery pack for

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

6 FAQs about [Lithium battery pack voltage container]

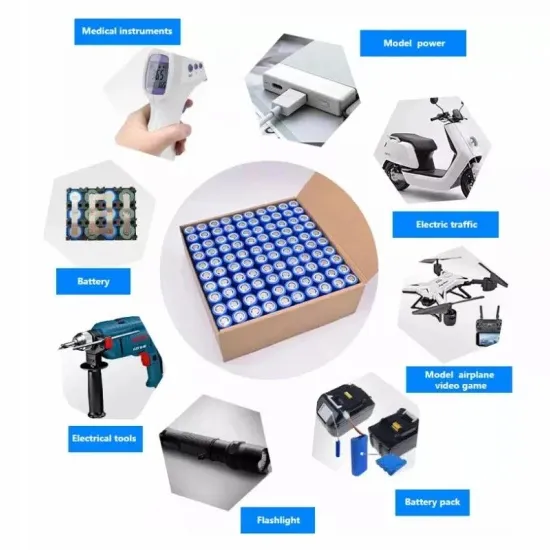

What is a lithium-ion battery pack?

Among various energy storage technologies, lithium-ion battery packs have emerged as the preferred choice due to their high energy density, long cycle life, and lightweight properties. In this blog post, we will delve into the key steps and considerations involved in designing a lithium-ion battery pack.

How safe is a lithium-ion battery pack?

Safety is paramount in lithium-ion battery pack design. Here are some key safety considerations: Overcharge Protection: Implement safeguards to prevent overcharging, which can lead to thermal runaway and fire. Over-Discharge Protection: Prevent cells from discharging below their safe voltage limit to avoid permanent damage.

What are the components of a battery pack?

• High-Voltage (HV) Components: Connectors, busbars, etc., for power transfer. • Low-Voltage (LV) Components: Connectors, wiring harnesses for communication and control (like the Battery Management System – BMS). (See Fig 1: Basic Battery Pack Structure)

What is a battery enclosure?

While the battery cells themselves get a lot of attention, the enclosure – the box that holds everything together – is just as critical. It’s more than just a container; it’s a vital structural component, a protective shield, and the interface between the battery and the vehicle or boat. 1 What’s a Lithium Battery Pack and Its Casing?

What are the different types of cooling options for a battery pack?

Options include passive cooling (heat sinks, thermal pads) and active cooling (fans, liquid cooling). Design Enclosure: Create a sturdy and lightweight enclosure to protect the battery pack components from physical damage, moisture, and dust. Ensure proper ventilation for the thermal management system.

What are the components of a battery?

• The Enclosure: Usually split into an upper cover and a lower case (or tray). • Li-ion Cells: The core energy storage units. • High-Voltage (HV) Components: Connectors, busbars, etc., for power transfer. • Low-Voltage (LV) Components: Connectors, wiring harnesses for communication and control (like the Battery Management System – BMS).

Learn More

- Bishkek battery pack lithium battery container

- Lithium battery pack 1000V high voltage charging and discharging

- High voltage lithium battery pack protection solution

- Full-charge voltage of lithium battery pack

- Lithium battery pack voltage type

- Lithium battery pack fast charging voltage

- What is the use of high voltage lithium battery pack

- Chisinau battery pack lithium battery container

- Minimum allowable voltage of lithium iron phosphate battery pack

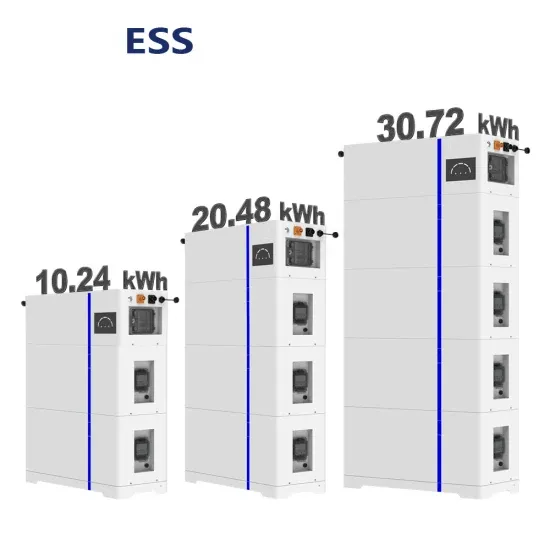

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.