Input Voltage is Too High... what to do?

Jan 3, 2021 · I have all the inverter settings at default values, Grid Upper Voltage Limit 132 VAC Grid Upper Voltage Limit 132 2021-01-03 14-31-58.png I suppose that is the safest however

Huawei SUN2000-3-10KTL-M1 Smart Hybrid Inverter

Nov 26, 2021 · *2 The maximum input voltage is the upper limit of the DC voltage. Any higher input DC voltage would probably damage inverter. *3 Any DC input voltage beyond the

Interpreting inverter datasheet and main parameters | AE 868

Both the maximum voltage value and operating voltage range of an inverter are two main parameters that should be taken into account when stringing the inverter and PV array. PV

How to avoid that solar inverters switch off at too high grid voltage

Jul 20, 2023 · Victron inverters synchronise with the grid, so output voltage will match input voltage, until you disconnect the grid input, or it exceeds the input limits and it defaults to the

Inverter efficiencies versus inverter input voltage. The

Inverter efficiencies versus inverter input voltage. The maximum efficiency values are marked with the prefix max in front of their product name, whilst the prefix euro stands for EURO

SUN2000-29.9/30/36/40KTL-M3

Jun 17, 2021 · The maximum input voltage is the upper limit of the DC voltage. Any higher input DC voltage would probably damage inverter. Any DC input voltage beyond the operating

SolaX X1-Hybrid-LV Datasheet EN V2.0-20250530

Jun 30, 2025 · 1 The maximum input voltage is the upper limit of the DC voltage. Any higher input DC voltage would probably damage the inverter 2 The AC frequency range may vary from

What is the high voltage threshold that causes a SMART UPS

Jun 29, 2021 · Nominal output voltage is set to the default of 230 volts and in the logs I can see VMAX hits 250v occasionally. The upper bypass limit is default at 255v so I am surprised that

Adjustment of sine voltage inverter: Upper input voltage limit

Jun 7, 2024 · Here is the question: Is the 16V upper voltage limit negotiable? The caps in the circuit are rated for 25V, the FETs for 40V. Does anyone know if it´s possible to increase the

SolaX X1-BOOST G4 Datasheet-En-V1

Jun 30, 2025 · 1 The maximum input voltage is the upper limit of the DC voltage. Any higher input DC voltage would probably damage the inverter 2 Input voltage exceeding the MPPT voltage

Understanding the Maximum Input Voltage of Inverters Key

This critical parameter defines the upper limit of voltage an inverter can handle from its power source. Whether you''re in renewable energy, industrial automation, or residential power

Decoding Inverter Parameters (Part I)

Jan 25, 2025 · If the PV input voltage is too low, power loss in the inverter''s boost circuit increases. If the PV input voltage is too high, it can cause power losses

What is the upper limit of the inverter AC voltage

The maximum input voltage for an inverter is a critical specification that ensures the device operates within safe limits. For a 12V inverter, the maximum input inverter voltage is

9. Inverter Settings

Sep 17, 2024 · To set the voltage at which the inverter restarts after low voltage shut-down. - To prevent rapid fluctuation between shut-down and start up, it is recommended that this value be

2004 DC Overvoltage

Apr 25, 2025 · Inverter,AlarmSuggestion Turn off the AC and DC switches, and check the input voltage. If the input voltage exceeds the upper limit, contact your vendor or technical support.

Array voltage sizing according to inverter

Aug 13, 2025 · The 2 first conditions are fuzzy conditions: if, during the simulation, the array voltage goes below the inverter limit VmppMin, or above the upper limit VmppMax, the inverter

Maximum Inverter Power Output Calculation | True

Dec 11, 2024 · Calculation Example: The maximum possible power output of an inverter is determined by multiplying the DC input voltage by the output current. This assumes 100%

difference between PV input and MPPT range

Aug 31, 2021 · MPPT Range is the voltage range (in this case 125V - 425V) over which your MPPT will operate effectively and be able to extract power from your array. PV Input Voltage

6 FAQs about [Inverter input voltage upper limit]

What is a maximum input voltage in a solar inverter?

The maximum input voltage defines the highest voltage the inverter can safely accept without causing damage. [Maximum input voltage] (Maximum input voltage in solar inverters) 2 indicates the upper voltage limit an inverter can handle. It’s crucial for ensuring long-term durability.

What is maximum input voltage?

Maximum input voltage is the threshold that your inverter can handle without damage. This value is particularly important when integrating solar panels with varying output characteristics. If the solar array's voltage exceeds this limit, it can cause overheating, component failure, or even complete inverter damage.

What is the maximum input voltage for a residential inverter?

Typically, residential inverters have a maximum input voltage between 500V and 1000V. Choosing one with a higher rating ensures greater flexibility and better performance in different weather conditions.

How many MPPT inputs does an inverter have?

Most inverters come with two MPPT inputs, allowing them to track two different arrays with different voltage profiles. Minimum startup voltage is the lowest voltage at which an inverter will begin operation. The minimum startup voltage 4 tells you the lowest point the inverter needs to begin functioning.

What parameters should be taken into consideration when stringing an inverter?

In addition, the datasheet specifies the maximum voltage value of the inverter. Both the maximum voltage value and operating voltage range of an inverter are two main parameters that should be taken into account when stringing the inverter and PV array.

What are the parameters of a PV inverter?

Aside from the operating voltage range, another main parameter is the start-up voltage. It is the lowest acceptable voltage that is needed for the inverter to kick on. Each inverter has a minimum input voltage value that cannot trigger the inverter to operate if the PV voltage is lower than what is listed in the specification sheet.

Learn More

- Relationship between inverter input voltage and battery voltage

- Solar inverter input voltage

- 27V inverter input voltage

- 800W inverter input voltage

- Inverter input voltage suddenly decreases

- Three-phase bridge inverter input voltage

- Inverter capable of adjusting input voltage

- Is the inverter output voltage 233v normal

- Communication 48V inverter bus voltage

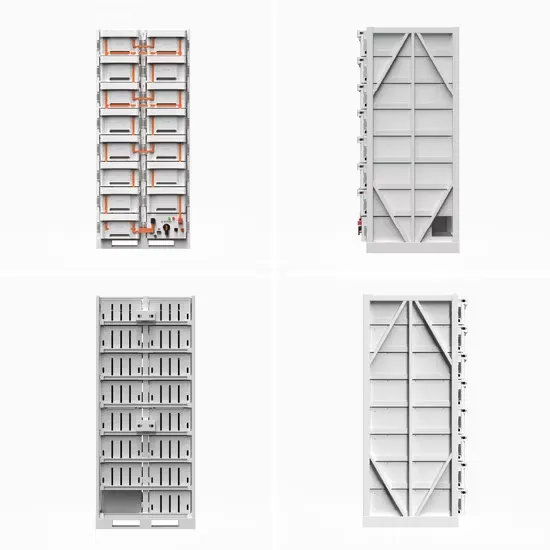

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.