DC link voltage for 3-phase inverter | Forum for

Nov 14, 2012 · Some inverters use a chopper in DC link or a controlled rectifier to control output voltage at various load (current) to overcome voltage loses. In

How to calculate low-power settings

Nov 28, 2019 · Your input low restart value, is the voltage that the inverter would turn back on after shutting down due to low battery voltage. This is generally a little above the nominal

How does the input voltage affect a power inverter?

Jul 3, 2025 · One of the most significant ways input voltage affects a power inverter is efficiency. Every inverter has an optimal input voltage range where it operates most efficiently. If the input

0003324927 575..661

Dec 23, 2017 · In the voltage-source inverter (VSI), the output voltage, vo, is a function of the inverter operation; the load current, io, is a function of the nature of the load; and the dc input,

Hybrid Inverters Redefine the Relationship Between the Inverter

Nov 22, 2024 · Hybrid inverters are redefining the relationship between solar energy systems and the grid by offering flexibility, energy independence, and enhanced efficiency.

Mppt voltage range vs max DC input voltage

Feb 14, 2024 · Note: there is something between the MPPT and inverter that converts the voltage from the panels to a constant voltage that the inverter can use. Some convert to a high voltage

What''s the reason for large VA vs W difference

Dec 28, 2022 · I''m using a new set-up of a 3.6 kW inverter with two 150 Ah gel batteries in series. I don''t understand why the inverter reports a much larger

DC‐link current analysis of three‐phase 2L‐VSI

Jan 1, 2018 · DC-link current is an important parameter for selection and design of DC-link capacitor or battery. Considering the AC current ripple, this study

Does An Inverter Increase Amp Hours On A Battery? Power

Apr 23, 2025 · When selecting an inverter for your battery system, consider the inverter''s power rating, efficiency, waveform type, input and output voltage, and compatibility with your battery

Understanding Inverter Input And Output: What

3 days ago · Input Voltage: The input voltage supplied from the DC source to the inverter follows the inverter voltage specifications, which start from 12V, 24V,

Importance of Open Circuit voltage with reference to an Inverter.

3 days ago · If I connect a string whose system voltage according to Voc > Max Input voltage of inverter but system voltage according to max operating voltage < Max input voltage, what''s

Inverters and harmonics (case studies of non-linear loads)

Jul 2, 2022 · An inverter comprises first of all a converter referred to as «mutator» i.e. switching device which converts the DC voltage supplied by a rectifier or a DC battery into AC voltage.

AKX00057-1

Jul 26, 2018 · While the output voltage of a two-level PWM inverter takes either the zero or High level, three-level and multilevel PWM inverters provide the output voltage at multiple levels by

difference between PV input and MPPT range

Aug 31, 2021 · this is my solar inverter datasheet i don''t get the difference between the MPPT and The PV input voltage my each pv in series should equal to 500v? or to 425?

Buck Converter – Circuit, Design, Operation and

3 days ago · The inverter for converting DC input voltage into AC, Transformer for stepping-up or stepping-down the AC voltage and finally the rectifier for

Relationship between inverter and battery current

Why do inverters use a higher voltage battery? Inverters are designed to operate at specific voltage levels (commonly 12V, 24V, or 48V). A higher voltage battery allows the inverter to

INVERTERS

Feb 4, 2019 · In such inverter units, battery supply is used as the input dc voltage source and the inverter circuit converts the dc into ac voltage of desired frequency. The achievable magnitude

What is relation between DC link voltage and

Jun 1, 2017 · The dc input voltage to the inverter in the pv systems is called the dc link voltage. Normally it comes from a DC to DC converter connected to the

Technical White Paper SolarEdge Single Phase Inverter

Sep 11, 2020 · Inverters The SolarEdge inverters employ a very high efficiency single-stage conversion, transformer-less topology. The SolarEdge inverter includes an independent

DC to AC power inverter and the relationship between the inverter

May 14, 2020 · The smaller the DIM value is, the larger the current output by the inverter will be. Voltage starting circuit: ENB is at high voltage. The inverter converts the dc energy (battery,

Inverter Current Calculator, Formula, Inverter Calculation

5 days ago · Inverter Current Formula: Inverter current is the electric current drawn by an inverter to supply power to connected loads. The current depends on the power output required by the

Battery connected to Inverter''s PV Input

Dec 22, 2022 · In the vast majority of cases, the input to a MPPT must be higher than the output battery voltage. MPPT have an input current limit. If not published, it is generally presumed to

What I Need to Know About Inverter and Battery?

What Is the Relationship Between Inverter and Battery? The inverter and battery work hand-in-hand to provide power in off-grid or solar energy systems. The battery stores the energy

6 FAQs about [Relationship between inverter input voltage and battery voltage]

What is voltage input & output in a battery inverter?

Voltage Input: This parameter refers to the voltage of the battery bank that the inverter will draw power from. Common battery voltages include 12V, 24V, and 48V, and choosing the correct voltage is essential for compatibility. Voltage Output: This parameter indicates the voltage of the AC power that the inverter produces.

What do you need to know about input power inverters?

Here are some important specifications that you need to know about input power inverters. Input Voltage: The input voltage supplied from the DC source to the inverter follows the inverter voltage specifications, which start from 12V, 24V, or 48V.

What is the difference between input voltage and input current?

Input Voltage: The input voltage supplied from the DC source to the inverter follows the inverter voltage specifications, which start from 12V, 24V, or 48V. Input Current: determines the amount of electric current required by the inverter based on the load and input voltage.

What voltage does a battery inverter use?

Common battery voltages include 12V, 24V, and 48V, and choosing the correct voltage is essential for compatibility. Voltage Output: This parameter indicates the voltage of the AC power that the inverter produces. Standard household voltage is typically 120V or 240V, depending on your location.

What is inverter output?

The inverter output is the electrical power generated by the inverter from the process of converting the DC input source into alternating current (AC).

What is the relationship between inverter input and output?

The relationship between inverter input and output itself is very closely intertwined, here are some of the relationships between inverter input and output. The amount of input source supplied to the inverter can determine the amount of energy available to be converted into output.

Learn More

- Battery voltage and inverter

- Relationship of voltage after inverter

- Inverter capable of adjusting input voltage

- Inverter input voltage suddenly decreases

- 800W inverter input voltage

- 27V inverter input voltage

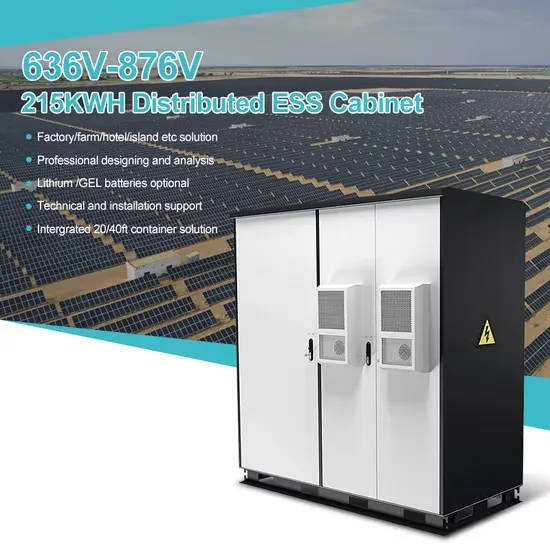

- What is the voltage difference of lithium iron phosphate battery station cabinet

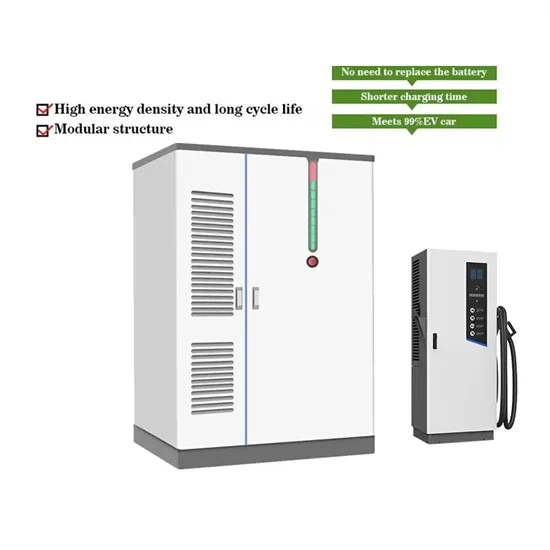

- Household energy storage lithium battery voltage

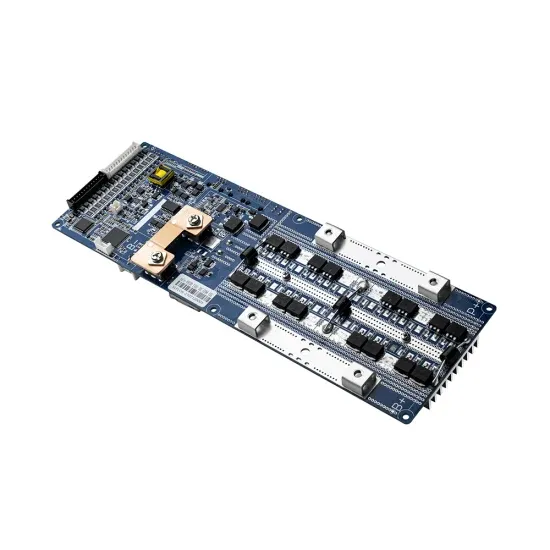

- Battery cabinet voltage regulator module

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.