INVERTER FR-D700 INSTRUCTION MANUAL (BASIC) 1

Jun 25, 2024 · Applying a voltage with voltage/current input switch in "I" position (current input is selected) or a current with switch in "V" position (voltage input is selected) could cause

CSM_Inverter_TG_E_1_1

Mar 27, 2016 · An inverter uses this feature to freely control the speed and torque of a motor. This type of control, in which the frequency and voltage are freely set, is called pulse width

AKX00057-1

Jul 26, 2018 · While the output voltage of a two-level PWM inverter takes either the zero or High level, three-level and multilevel PWM inverters provide the output voltage at multiple levels by

6. Troubleshooting and Support

Jun 17, 2025 · In this case the output voltage will quickly decrease to limit the output current of the inverter. If the over current trip level is continuously exceeded, the inverter will shut down: wait

why your solar inverter might be tripping or

Apr 16, 2024 · In the context of solar inverters, it might refer to a situation where the inverter shuts down (trips) and then automatically restarts (CB). Here are

Reasons for solar panel fluctuation + 6 main

Jan 29, 2025 · 5- Voltage drops: Voltage drops in the input power supply can lead to fluctuations in the output power of the inverter. To solve this, ensure that the

10 common inverter failure and the solutions –

Nov 15, 2023 · Common causes and solutions for low DC input voltage: The open circuit voltage of the string should be much greater than the minimum input

What should I do if the inverter power supply module fails?

Sep 26, 2019 · Voltage increases gradually during withstand voltage test. Select inverter power module with high withstand voltage; When welding inverter power supply module, the

How to Troubleshoot and Fix Common Inverter

6 days ago · Check the input voltage. The input voltage to the inverter should be within the specified range. If the input voltage is too low or too high, the

The Power Curve for Energy Management Decreases or Decreases

Symptom Description When the external light is normal, the output power of the inverter suddenly drops to zero (excluding zero-power grid-tied scenarios). The inverter may be in grid-tied, fault

Key Inverter Parameter: Maximum PV Input Voltage

Aug 28, 2024 · The maximum PV input voltage represents the highest DC voltage that a PV inverter can safely handle. This parameter defines the upper limit for the open-circuit voltage of

How to Address Inverter Low Voltage Issues for

Apr 3, 2025 · Inverter low voltage is a common issue that can disrupt industrial operations, affecting automation systems and energy management efficiency.

10 common inverter failure and the solutions –

Nov 15, 2023 · This article will give you an overall guide on the reasons of 10 common inverter failure and the solutions step by step to solve these problems.

Summary of common causes and countermeasures of inverter

Common causes and countermeasures of inverter failures Causes of inverter undervoltage failure: 1. Power supply phase loss Cause: When the inverter power supply phase is lost, the three

Solar Panel Voltage Drops Under Load (Problem

Dec 21, 2022 · Again, the problem can be the controller, inverter, or panel. Do You Need to Determine the Source of a Drop-in Voltage from a Solar Panel? If

Inverter Voltage Drop Issue – How to Solve

Dec 21, 2021 · Whenever PWM is employed in an inverter for enabling a sine wave output, inverter voltage drop becomes a major issue, especially if the parameters are not calculated

Understand the working principle of photovoltaic inverters in

Because the terminal voltage of the solar cell changes with the load and the intensity of sunlight. Especially when the battery is aging, its terminal voltage varies widely. For example, the

On sunny days, Inverter switches off when DC voltage gets

May 28, 2023 · The technical info for this inverter is: Input DC (PV side) Recommended max PV power 8000w Max input voltage 600v Rated voltage 330v MPPT voltage range 90-520v Full

How does the input voltage affect a power inverter?

Jul 3, 2025 · As the battery is used, the voltage gradually decreases. This means that the input voltage to the inverter will also change over time. An inverter that can handle a wide range of

Multiplus IIgx+external current sensor–delayed

Apr 20, 2025 · Multiplus II GX with external current sensor – delayed inverter reaction after AC input restore (ESS: Optimized without BatteryLife) until

Why Your Residential Inverter Keeps Tripping and How to Fix

Apr 14, 2025 · Incorrect input voltage is a common issue. How to Fix an Inverter That Keeps Tripping Let''s go through step-by-step solutions based on the problem. 1. Reduce the Load

6 FAQs about [Inverter input voltage suddenly decreases]

Why is my inverter low voltage?

Another possible cause could be an inadequate power source or improper electrical connections. Faulty wiring can also result in voltage fluctuations. If you are experiencing inverter low voltage problems, it's essential to diagnose the issue accurately. Start by checking the battery health.

How to troubleshoot an inverter?

Once you have identified the problem, you can begin troubleshooting it. Here are some steps to follow: Check the input voltage. The input voltage to the inverter should be within the specified range. If the input voltage is too low or too high, the inverter may not function properly. Check the output voltage and frequency.

Why is my inverter screen not working?

Reason 3: The DC input voltage is too low. When the string output voltage is lower than the minimum input voltage of the inverter, there is no display on the inverter screen. To make sure, you can use a multimeter to measure the output voltage of the photovoltaic string to see whether the voltage reaches the minimum input voltage of the inverter.

What causes a DC inverter to overvoltage?

This can arise from high inertia loads decelerating too quickly, the motor turns into a generator and increases the inverter’s DC voltage. There are other causes of DC overvoltage, however. POSSIBLE FIXES: Turn the overvoltage controller is on. Check supply voltage for constant or transient high voltage. Increase deceleration time.

What is inverter low voltage?

Now that we know what inverter low voltage is, let's explore some common causes behind it. One prevalent cause could be a faulty battery. An old or damaged battery may not be able to provide sufficient power, leading to low voltage from the inverter. Another possible cause could be an inadequate power source or improper electrical connections.

Why does my inverter keep shutting down?

The inverter will shut down if the input voltage from the battery drops too low (often below 10.5V). This protects the battery from damage. Recharge or replace the battery to bring the voltage back to a sufficient level. Check for a charging system failure if the battery isn’t recharging properly.

Learn More

- Solar inverter input voltage

- 800W inverter input voltage

- Relationship between inverter input voltage and battery voltage

- 27V inverter input voltage

- Inverter input voltage upper limit

- Does the inverter have low voltage protection

- Inverter discharge has voltage

- Three-phase inverter DC side voltage

- Inverter with protection voltage

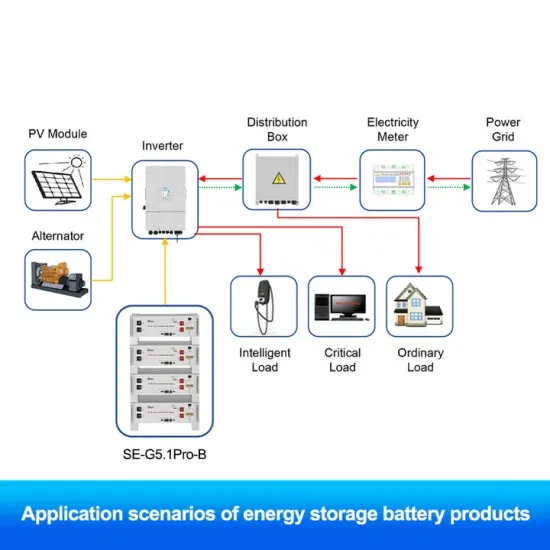

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.