What is Partial Discharge in an Inverter-Driven Motor? | Hioki

In general, partial discharge occurs when a voltage greater than approximately 350 V is applied to a poorly insulated winding. Consequently, not only inverter-driven motors but also high-voltage

Powerwall 3 Datasheet

Apr 24, 2025 · Powerwall 3 achieves this by supporting up to 20 kW DC of solar and providing up to 11.5 kW AC of continuous power per unit. It has the ability to start heavy loads rated up to

DC Link Capacitor Active Discharge by IGBT Weak Short Circuit

Apr 2, 2019 · DC link active discharge is mandatory in new energy vehicles. This paper first analyzes the necessity of active discharge in automotive inverters and then introduces the

Battery Discharge: solar battery bank discharge explained

The voltage of a lead acid battery when idle (not supplying current or being charged) will vary according to how fully charged the battery is. The graph shown below represents the

A DC-Link Hybrid Active Discharge Scheme for Traction Inverters

Sep 6, 2024 · when an Electrical Vehicle (EV) encounters an accident or the vehicle is taken to a service station, the DC-link capacitor in the inverter must be discharged to ensure safety of

Passive discharge circuit at input terminal of inverter

The active discharge circuit of existing inverter input is DC-to-dc converter (DC-DCConverter), and its two inputs are identical with two inputs of inverter.But DC-to-dc converter needs certain

Understanding Cut Off Voltage: Key to Extending Tubular

Mechanism of Low Voltage Battery Cut off The inverter or charge controller continuously monitors the battery''s voltage level. When the voltage approaches the predefined cut-off threshold, it

Deye 5kw hybrid inverter Battery Settings (LOW

Nov 9, 2022 · 1. LOW BAT Low battery voltage or % (battery symbol on the home screen will turn yellow). Stopping point for TOU. 2. SHUT DOWN Battery voltage or % at which the inverter

A 13-level switched-capacitor-based multilevel inverter with

Jan 2, 2025 · Compared to other 13-level switched-capacitor inverters, the proposed structure utilizes fewer components, capacitors with lower maximum voltage, and fewer conduction

Ignores discharge power to float voltage

Jun 27, 2025 · For many BMS (passive) the behaviour of charge/discharge around 100% is completly normal, and related to battery balancing, because everytime a single cell is

Design Priorities in EV Traction Inverter With Optimum

Apr 1, 2023 · Weight and power density – The wide band-gap switch and powertrain integration are the key technologies enabling high-power density inverter design. The inverter power

Cannot charge after Smartlithium battery got deeply

Dec 13, 2024 · I use a MultiPlus Compact with a 330ah smart lithium battery in a camper van. The battery got deeply discharged recently. The low voltage warning popped up, and the Victron

What is Partial Discharge in an Inverter-Driven Motor? | Hioki

High-voltage inverter-driven motors, such as those found in EVs, are more prone to partial discharge phenomena. In general, partial discharge occurs when a voltage greater than

An eleven level single source switched capacitor boost inverter

3 days ago · The proposed structure, which consists of a single voltage source, 10 power electronic switches, 3 capacitors, and one diode, generates an 11-level stepped voltage

48v inverter low voltage cutoff leaves so much on the table.

Jun 8, 2021 · Regarding low voltage cut off by inverters. How do you all deal with inverters that cut off long before your bms(s) will? My xyz 3000w inverter cuts ac power at about 46.5 input

Active Discharge and Pre-charge of EV High Voltage

Apr 20, 2023 · BMS Active Discharge with THYRISTOR Fast Discharge prevents Fire hazard actively discharged to prevent residual voltage. separate disconnection unit. power resistors

How to Reduce the Power Resistor for DC-Link

Aug 16, 2024 · The DC-Link capacitor is a part of every traction inverter and is positioned in parallel with the high-voltage battery and the power stage (see Figure 1). The DC-Link

Troubleshooting Inverter Battery Drainage: Causes Solutions

Dec 6, 2023 · Discover why your inverter battery may be draining quickly and learn effective solutions to optimize its performance. From excessive loads to poor maintenance.

Passive high-voltage DC bus discharge circuit for a vehicle

A vehicle includes a rechargeable energy storage system (RESS), an electric traction motor, a traction power inverter module (TPIM), a high-voltage direct current (HVDC) bus that

4. Configuration

Nov 2, 2022 · The inverter will restart again once the battery voltage has increased above the "low battery restart and alarm" level. The inverter will clear the low battery alarm once it detects the

6 FAQs about [Inverter discharge has voltage]

Do EV traction inverters need a DC link active discharge?

Every EV traction inverter requires a DC link active discharge as a safety-critical function. The discharge circuit is required to discharge the energy in the DC link capacitor under the following conditions and requirements: Power transistor on, off control using the TPSI3050-Q1.

Why do EV inverters need to be discharged?

Abstract: when an Electrical Vehicle (EV) encounters an accident or the vehicle is taken to a service station, the DC-link capacitor in the inverter must be discharged to ensure safety of both the passengers and the operator.

What is the charge and discharge limit of my inverter?

Please refer to the manual for the charge and discharge limit of your inverter. When selecting the charge and discharge current limits you will always be limited to the lowest current value whether that is the inverter or the batteries. For example, the 3.6kW Ecco inverter has a 90A maximum charge/discharge current.

How is power dissipated in an inverter?

The power dissipated by the the inverter’s housi ng or through a cooling s ystem. the current. The discharge energy is used to charge the Low- voltage battery (12 V) us ed as an auxiliary bat tery. the Flyback transformer. A charging current of 1C is used to Ampere ho urs (Ah). The blue trace i n Fig.1 illustrates the energy

How do EV traction inverters work?

To control the voltage so that the voltage does not exceed 50 V (touch safe), the auxiliary power supply has to turn on and power up safety-relevant circuits that can discharge the DC link caps (active discharge) or actively short circuit the motor. Every EV traction inverter requires a DC link active discharge as a safety-critical function.

What is the maximum charge/discharge current for an Ecco inverter?

For example, the 3.6kW Ecco inverter has a 90A maximum charge/discharge current. Two 5.12/5.32kWh batteries have a continuous discharge of 100A. This means that the maximum charge/discharge is limited to the 90A of the inverter.

Learn More

- Inverter rated phase voltage

- How much is the inverter DC high voltage

- 12v inverter protection voltage change

- 35kv high voltage inverter

- Inverter and component voltage matching

- Huawei inverter voltage

- High voltage inverter overall equipment

- Morocco high voltage energy storage inverter manufacturer

- Inverter input voltage suddenly decreases

Industrial & Commercial Energy Storage Market Growth

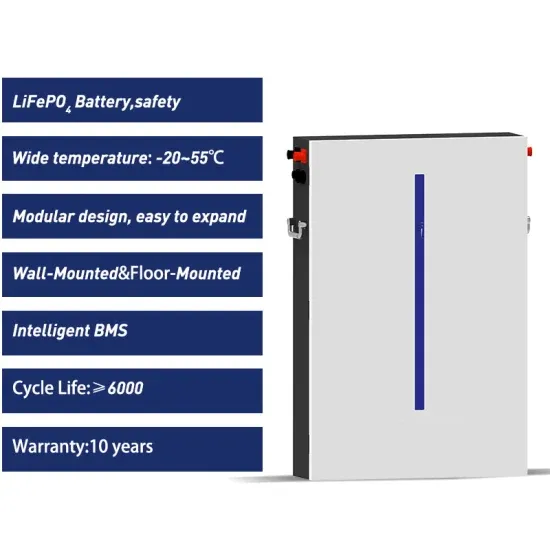

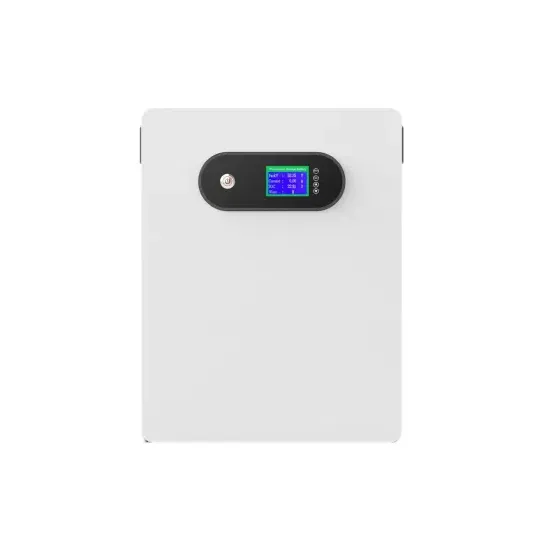

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.