Demystifying high-voltage power electronics for solar

Apr 1, 2023 · One of the key subsystems in PV generation is the inverter. Advancements in high-voltage power electronics are resulting in more intelligent, more lossless and smaller PV

ZCH100 Series High Voltage Inverter

Dec 25, 2024 · Preface to the manual ZCH100 series high-voltage inverter is a strategically important industrial intelligent high-voltage inverter control system launched by Shanghai

High-voltage VS Low-voltage Inverters: What''s the difference?

May 14, 2025 · Confused about high-voltage vs low-voltage inverters? This easy-to-read guide explains the differences, pros, cons, and real-world uses—perfect for anyone exploring solar

Trends in High Voltage Inverter Systems

Jan 1, 2023 · Current EV (Electric Vehicle) technology is effective but where is it going in the future? This paper looks at the current trends in the EV market to increase efficiency and

High Voltage Inverter

Aug 6, 2025 · The inverter for electric vehicles serves as the powerful conductor, seamlessly converting battery''s direct current (DC) into alternating current (AC) to propel the vehicle with

High Voltage Inverters & Batteries | Solar Warehouse SA

A high voltage inverter is a device that converts the direct current (DC) electricity from solar panels or batteries into high voltage alternating current (AC) electricity that can be used by

Unlocking the power of high voltage

Aug 12, 2025 · Designing high-voltage applications comes with a unique set of challenges. That''s why our power conversion, current and voltage sensing, isolation and real-time control

Selecting High Input Voltage Inverters: Factors to Consider

Feb 28, 2024 · In today''s modern world, the need to convert DC power into AC power is growing rapidly. This is where high input voltage inverters come into play. Whether you are working in

Yokogawa''s High-Voltage, Wide-Bandwidth Oscilloscope

Feb 19, 2025 · Yokogawa said its latest high-voltage, wide-bandwidth probe can stay on top of the faster switching speeds of next-generation power electronics like SiC.

The Technology Behind High Input Voltage Inverters

Feb 22, 2024 · This ensures the longevity and reliability of connected loads. In conclusion, high input voltage inverters have revolutionized the power conversion landscape. Their ability to

High Voltage Inverters for Large-Scale Industrial Power

A High Voltage Inverter is a device used to convert a fixed input voltage into a variable output voltage at a higher level. It is commonly employed in various industrial applications. For

MACMIC Launches 1700V IGBT Products, Widely Used in High-Voltage

Oct 23, 2023 · The cascade H-bridge topology is simple, flexible, and widely applied in high-voltage cascade inverters, Static Var Generators (SVG), and cascade H-bridge energy storage

High Voltage Inverter: Unlocking the Potential of High

Aug 17, 2025 · Due to its ability to handle high voltages, its use allows the operation of devices with large loads while ensuring precise control and optimal energy efficiency. This article will

BorgWarner Secures Another Dual Inverter Project with

Jul 31, 2025 · The adaptive battery voltage regulation greatly extends the motor''s constant power and high efficiency operating ranges, improving overall system efficiency. BorgWarner''s dual

Analysis of the Working Principle and Application of High Voltage Inverter

May 15, 2024 · The working principle of high voltage inverter is to control the speed of motor by changing the frequency of alternating current (AC), MICNO high voltage inverter adopts

Which Industries Are Harnessing the Power of

Apr 18, 2024 · Industrial applications often demand high voltage power inverters to drive machinery and equipment efficiently. From variable frequency drives

Maximize Efficiency with Advanced high voltage inverter for

Explore the latest high voltage inverter to optimize energy efficiency and minimize cost. Improve one''s enterprise''s sustainability with technology designed for seamless integration and

Huaneng × Sungrow: The world''s first 2000V photovoltaic

Jul 3, 2023 · The high voltage and high power density of inverters have always been an important innovation direction for reducing costs and increasing efficiency in photovoltaics. Recently, the

6 FAQs about [High voltage inverter overall equipment]

Who develops high voltage inverter systems for electric vehicles?

The vehicle manufactures and automotive tier 1 suppliers develop inverter systems for electric vehicles. Discussions were held with their design and research teams during direct meetings to understand future developments. Through these discussions, along with our own research, there are some clear high voltage inverter trends in the EV market. 3.

How can a high voltage inverter improve EV performance?

A better approach is to increase efficiency and decrease weight which extends the range of the EV and potentially reduces vehicle cost and running expenses. A significant contributor to achieving this is the inclusion of enhanced control, high voltage inverter modules in the vehicle. * Corresponding author.

What is a multilevel converter in Siemens Energy HVDC PLUS?

In Siemens Energy HVDC PLUS systems, one modular multilevel converter comprises three Single-phase inverter. One converter comprises three identical phase units with two converter arms, and each converter arm contains a number of sub modules supporting the full DC voltage.

What is a Modular Multilevel Converter?

The Modular Multilevel Converter, introduced for HVDC by Siemens Energy more than a decade ago, is the well-established standard for high voltage, high power VSC applications today. In Siemens Energy HVDC PLUS systems, one modular multilevel converter comprises three Single-phase inverter.

Which EC-C converter is suitable for two different voltage levels?

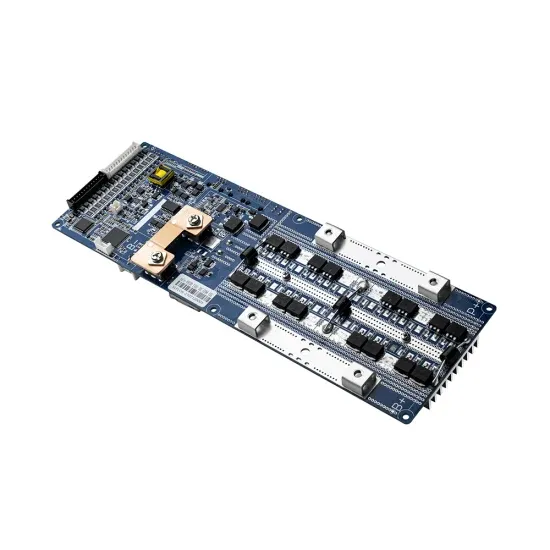

EC-C converter is available as two variants suitable for two different system voltage levels as EC-C1200-450 and as EC-C1700B-420. The EC-C1200-450 is meant for up to 850VDC/500VAC voltage levels and the EC-C1700B-420 is meant for up to 1200VDC/690VAC voltage levels.

What is the operating voltage range of ec-c1200-1200?

The EC-C1200-1200 is a heavy-duty converter. It is specifically developed for commercial electric vehicle applications. Operating voltage input range for EC-C1200F-1200-440 is 250-440 VDC and for EC-C1200F-1200-750 is 450-750 VDC. Features and benefits *EC-C1200F-1200 converter is only running with eDrivetrain and eTraction system.

Learn More

- Georgia High Voltage Inverter Manufacturer

- High frequency inverter post-stage voltage stabilization components

- Inverter high voltage main frequency or low voltage mixed frequency

- 12v to 500 high voltage inverter production

- The higher the voltage the higher the high frequency inverter

- The inverter output high voltage drops instantly

- High frequency inverter capacitor and resistor voltage reduction

- Does the inverter have high voltage

- High voltage inverter design

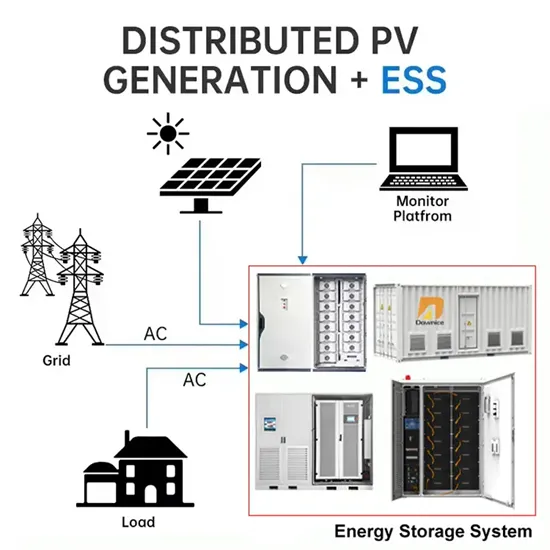

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.