Traction inverter design resources | TI

Our integrated circuits and reference designs allow you to create traction inverter designs that efficiently convert DC power to alternating phases of power to drive multi-phase motors.

Infineon high voltage Inverter Application Presentation

May 25, 2025 · Infineon''s industry-leading discrete IGBTs are compatible with Empower''s latest generation inverter in terms of packaging. Together with the high current density, ultra-low

Hardware Design of Two Level Inverters for High Voltage

Jan 19, 2014 · Abstract Abstract Abstract – –– The The The efficient efficient efficient design design design of of of inverter inverter inverter becomes becomes becomes apparently

The Technology Behind High Input Voltage Inverters

Feb 22, 2024 · This ensures the longevity and reliability of connected loads. In conclusion, high input voltage inverters have revolutionized the power conversion landscape. Their ability to

High-voltage inverter | EV traction inverter | Eaton

Feb 1, 2024 · The high-voltage inverter converts direct current (DC) from the batteries or generator to alternating current (AC) to power the traction drive

Voltage Source Inverter Reference Design (Rev. E)

May 11, 2022 · Description This reference design implements single-phase inverter (DC/AC) control using a C2000TM microcontroller (MCU). The design supports two modes of operation

High Voltage Solar Inverter DC-AC Kit

Sep 3, 2014 · High Voltage Solar Inverter DC-AC Kit 1 Introduction Inverters, especially solar inverters, have gained more attention in recent years. Solar inverters produce solar energy

High-Voltage, High-Power Density Traction Drive Inverter

Jun 11, 2019 · Produce a design for 100kW high-voltage inverter and validate the design via simulation Evaluate the impact of selected topology on meeting the power density target

Three-phase inverter reference design for 200-480VAC

May 11, 2022 · The three-phase inverter uses insulated gate bipolar transistor (IGBT) switches which have advantages of high input impedance as the gate is insulated, has a rapid response

Design Priorities in EV Traction Inverter With Optimum

Apr 1, 2023 · ABSTRACT This technical white paper explores key system trends, architecture, and technology for traction inverters. The devices and technologies used to enable traction

Grid Connected Inverter Reference Design (Rev. D)

May 11, 2022 · Description This reference design implements single-phase inverter (DC/AC) control using a C2000TM microcontroller (MCU). The design supports two modes of operation

Voltage Source Inverter Reference Design (Rev. C)

Feb 6, 2022 · 1 Description This reference design implements single-phase inverter (DC/AC) control using a C2000TM microcontroller (MCU). The design supports two modes of operation

High-Voltage, High-Power Density Traction Drive Inverter

Jun 11, 2019 · Go/No-Go decision: Produce a design for 100kW inverter power stage and determine if design can meet DOE ELT 2025 targets. If the selected design can significantly

EV Traction Motor Power Inverter Control Reference

Aug 25, 2022 · This reference design is a high-voltage inverter solution implemented for hybrid electric vehicle and electric vehicle traction control systems. It includes efficient system

Reinforced Isolation 3-Phase Inverter With Current

Aug 25, 2023 · Design Overview This design provides a reference solution for a three-phase inverter rated up to 10 kW, designed using reinforced isolated dual IGBT gate driver

Automotive, High-Power, High-Performance SiC Traction

May 5, 2025 · Description This reference design is an 800V, 300kW silicon carbide (SiC) based traction inverter developed by Texas Instruments and Wolfspeed®. This design provides a

Voltage Source Inverter Design Guide

Aug 25, 2017 · This design uses devices from the C2000TM microcontroller family to implement control of a voltage source inverter. An LC output filter is used to filter the switching component

High Voltage Solutions in HEV/EV Part II:

Aug 19, 2025 · The DC/DC converter provides transfer of energy between the higher voltage battery system and the lower voltage (typically 12V) systems. The higher voltage supplies

High Voltage Seminar

Jun 26, 2023 · Switching losses and voltage overshoot increase as load current increases. Fully charged battery = lower overshoot headroom. More overshoot headroom for majority of battery

A bidirectional, sinusoidal, high-frequency inverter

Oct 29, 2015 · An inverter design method based on the use of a converter to convert the direct input voltage to rectified sine wave and a power bridge to produce the alternating output

HV-IGBT Module for High-Performance Inverter Design

Aug 16, 2025 · To meet growing demands for energy-efficient and reliable inverter systems in traction applications, Mitsubishi Electric has introduced the XB-Series high-voltage IGBT

6 FAQs about [High voltage inverter design]

What is a high power switch in an inverter?

The high-power switches are the most critical component in the inverter as they control the flow of current to the motor to generate motion. As such, the switches' are monitored and protected by sensing their temperature, voltage and current throughout their operation.

How does a high-voltage full bridge inverter work?

A high-voltage full bridge inverter works by converting the DC voltage V1 to a high-frequency square wave AC voltage. This AC voltage is then supplied to a 20kHz frequency high-voltage transformer T1, which, after the boost rectifier, provides power to the load. The inverter high-voltage full bridge drives the routing components and the IGBT power modules.

What is the main circuit of an inverter?

The main circuit of an inverter includes an inverter DC power supply, IGBT bridge inverter, protection circuits, high frequency high voltage transformers, and high frequency high voltage silicon stack (Rectifier).

Does EV traction inverter have a power module?

EV Traction Inverter Control Reference Design Gen 3. Note: Mechanical chassis, link capacitor, bus bar, cooling fixture and Power module are not included, but could be purchased through our partner Vepco that offer a complete inverter assembly For additional information contact support or your sales representative.

What is a traction inverter?

The traction inverter is vital to the drive system and includes protection and monitoring auxiliary circuits to prevent system-level failure modes such as over- and under-torque, unintentional motor commutation, or motor shutdown.

How does an inverter amplify a PWM signal?

A closer look at the inverter, shown in Figure 2-5, reveals six total semiconductor power switching devices with a gate driver to amplify the PWM signal from the MCU. The three legs of the inverter convert the DC battery voltage into three phases of AC voltage and current to drive the motor.

Learn More

- The higher the voltage the higher the high frequency inverter

- Inverter high voltage large capacitor

- Inverter high voltage output price

- Ottawa high voltage inverter manufacturer

- Georgia High Voltage Inverter Manufacturer

- Azerbaijan high quality low voltage inverter price

- 12v inverter high voltage

- High frequency inverter capacitor and resistor voltage reduction

- 35kv high voltage inverter

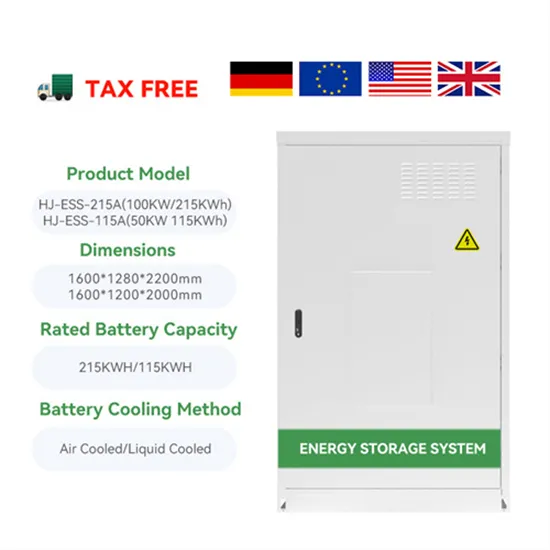

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.