DC Link Capacitor Calculation for Inverter

Oct 5, 2024 · Learn how to calculate the DC link capacitor for inverters, taking into account power rating, voltage ripple, switching frequency, and load dynamics. Ensure your inverter operates

Design Capacitors for Applications | DigiKey

May 13, 2016 · The importance of dielectric materials, ESR, ripple current and other parameters when selecting DC link capacitors for maximum performance in DC link circuits.

Explanation of Inverter DC Capacitance and Inrush Current

Dec 14, 2023 · Explanation of Inverter DC Capacitance and Inrush Current What is Inverter DC Capacitance? All modern power inverters have a large capacitor bank at their DC input

Importance of DC-Link Capacitors in High Power

Mar 11, 2025 · Introduction In high-power inverter designs, such as those used in electric vehicles, renewable energy systems, industrial motor drives, and high

An eleven level single source switched capacitor boost inverter

2 days ago · The proposed structure, which consists of a single voltage source, 10 power electronic switches, 3 capacitors, and one diode, generates an 11-level stepped voltage

Scalable Bidirectional Switched-Capacitor Multilevel Inverter

May 8, 2025 · In this article, a novel switched-capacitor basic cell is introduced as the building block of a multilevel power-electronic inverter. Two distinct modulation strategies are proposed

Three-level boost inverter with capacitor voltage self

Aug 8, 2023 · At last, an inverter prototype with a 1 kW power rating is built, and the obtained results demonstrate that this inverter possesses the following superiorities: a wider range of

A DC Bus Capacitor Design Method for Various Inverter

Feb 21, 2024 · Abstract - This paper involves the selection and sizing of the appropriate type of dc bus capacitor for various applications utilizing PWM operated three-phase voltage source

High-Energy Density Capacitors for Electric Vehicle Traction Inverters

Jun 26, 2020 · DC bus capacitors take up substantial space in a traction inverter, limiting the traction drive power density. Thus, several commercial capacitor technologies, under

A 13-level switched-capacitor-based multilevel inverter with

Jan 2, 2025 · Compared to other 13-level switched-capacitor inverters, the proposed structure utilizes fewer components, capacitors with lower maximum voltage, and fewer conduction

Efficient switchedâ capacitor multilevel inverters for

May 11, 2023 · Switched-capacitor multilevel inverters are suitable topologies for renewable and sustain-able energy due to a low number of dc-link voltages. This article presents two

Selection and calculation of dclink capacitor in

Dc-link capacitors are considered as one of the sensitive parts of the grid connected photovoltaic systems and needs effort to design a reliable and optimal size capacitor as its reliability is

Capacitors in inverter circuitry... | DIY Solar Power Forum

May 26, 2021 · The big caps in an inverter smooth out pulses of current drawn by high frequency step up SMPS (HF inverters) and store the boosted voltage (HF inverters), They smooth the

Designing a high voltage DC-link capacitor

Apr 23, 2024 · Introduction Electric vehicles (EVs) typically feature a large DC link capacitor (C DC LINK) to minimize voltage ripple at the input of the traction

Capacitors | Products | TDK Product Center

4 days ago · Aluminum electrolytic capacitors are an attractive solution here since they can fulfill the key requirements, such as high voltage ratings of up to 500

A review on topology and control strategies of high-power inverters

Feb 15, 2025 · In order to efficiently and fully utilize the received energy from solar panels in LS-PV-PP, high-power inverters play an important role in converting the received DC energy from

A Novel High-Gain Switched-Capacitor Multilevel Inverter

Nov 1, 2024 · This paper introduces a novel Multi-Level Inverter (MLI) design which utilizes a single input and leverages capacitor voltages source to generate a four-fold increase in output

A New Reliable Switched-Capacitor-Based High Step-Up

ABSTRACTThis article presents a new transformerless switched-capacitor (SC) based five-level grid- connected inverter with inherent voltage-boosting capability. The proposed topology

High power T-type-based multi-level inverter for electric

Nov 1, 2023 · This paper presents an extension of a 5-level T-Type inverter to a high-power multi-level inverter that can be implemented in electric vehicles and trucks. The proposed inverter

What is a DC Link Capacitor? | Capacitor Connect

Aug 17, 2025 · High frequency switching circuits with DC link enable to get rid of transformers, and allow large flexibility in output voltage and frequency levels. DC Link capacitor is subject to

How is inverter bus capacitance chosen?

Dec 5, 2020 · Does anyone know how the bus capacitance of an inverter is chosen? I have been told that a 6kW inverter should have 0.1F from one source, and 0.028F from another source.

Capacitors for High Power

Mar 21, 2024 · The DC-link capacitor''s purpose is to provide a more stable DC voltage, limiting fluctuations as the inverter sporadically demands heavy current. A design can use different

6 FAQs about [Inverter high voltage large capacitor]

Does Adding capacitance improve the performance of an inverter?

So beyond a certain point, adding capacitance does little to enhance the performance of the inverter. = 308 uF That’s 16 times less capacitance than that of the electrolytic capacitor! Certainly packaging a 308 uF capacitor verses a 5,000uF capacitor makes for a smaller, lighter and more compact design.

Are film capacitors a good choice for inverter power bridges?

Moreover, modern film capacitors not only perform better but can be a cost effective technology as well if applied correctly. inductance in an inverter power bridge leads to inefficiencies due to the voltage spikes they produce when the power devices are switched on and off at a high rate of dI/dt.

Are electrolytic capacitors good for hard switched inverter bus link capacitors?

Electrolytic capacitors have been the workhorse technology for hard switched inverter bus link capacitors for many years. Electrolytic capacitor technology has also remained virtually unchanged over the years. Up till now, the greatest benefit in using electrolytic capacitors for bus link capacitors in inverters has been their cost.

What is a DC link capacitor?

What is an Inverter? What is a Converter? The DC-link capacitor's purpose is to provide a more stable DC voltage, limiting fluctuations as the inverter sporadically demands heavy current. A design can use different technologies for DC-Link capacitors such as aluminum electrolytic, film, and ceramic types.

How to sizing capacitors for inverter bus link applications?

The first step in sizing capacitors for inverter bus link applications should be to understand how much bus link capacitance is required for a given inverter design. The biggest design limitation for electrolytic capacitors in inverter applications has been the amount of ripple current that the electrolytic capacitor can sustain.

What type of capacitor is best for power electronics?

Typically, aluminum electrolytic capacitors are the best option for power electronics applications requiring high capacitance (100’s of μF to Farads), up to 550 Vdc. current capacitor DC Link applications DC Link film caps meet bus voltage applications between 450 – 1300 Vdc. Custom DC Link designs available up

Learn More

- High frequency inverter capacitor and resistor voltage reduction

- High voltage inverter design

- How many meters is the high voltage inverter safe

- High frequency inverter post-stage voltage stabilization components

- The higher the voltage the higher the high frequency inverter

- Inverter high voltage main frequency or low voltage mixed frequency

- The inverter output high voltage drops instantly

- Inverter high voltage output price

- 35kv high voltage inverter

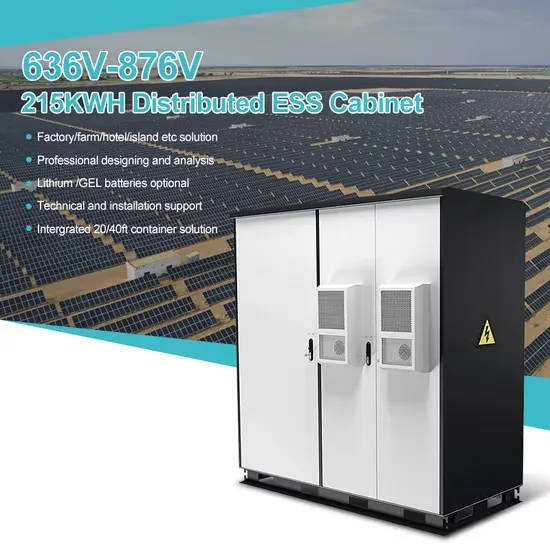

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

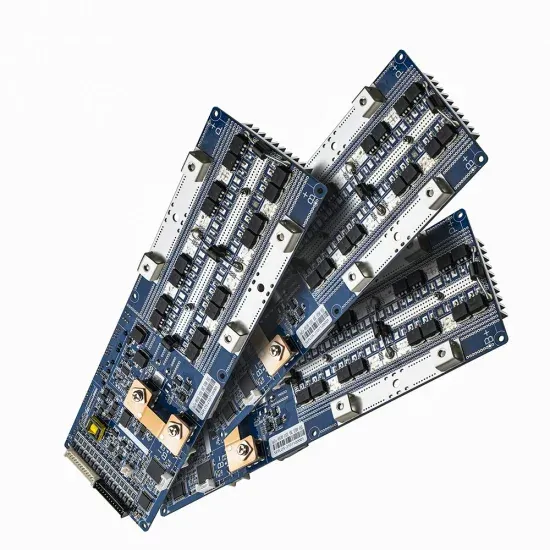

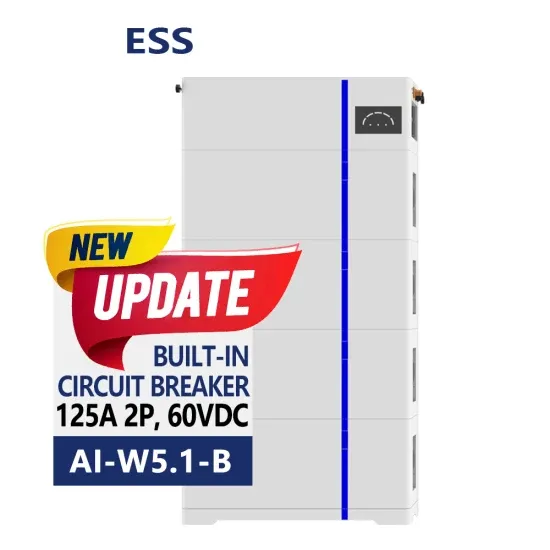

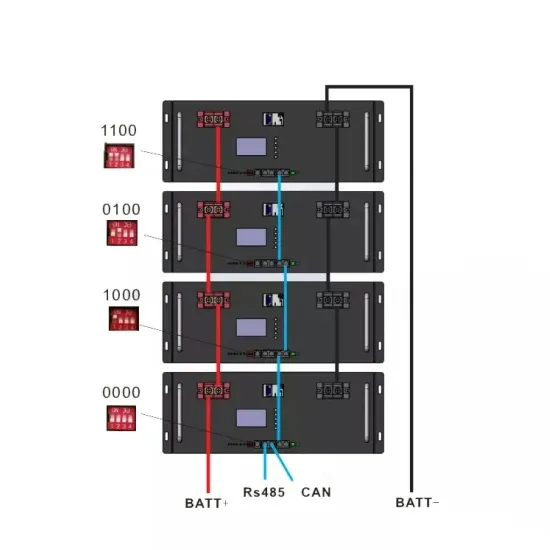

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.