2004 DC Overvoltage

Apr 25, 2025 · Inverter,AlarmSuggestion Turn off the AC and DC switches, and check the input voltage. If the input voltage exceeds the upper limit, contact your vendor or technical support.

Using Huawei SUN2000 inverters with high /A ratios

Jan 14, 2025 · Provided that the system is designed with these constraints in mind, high DC/AC ratios will not cause any detrimental effects to the reliability, lifetime or warranty of Huawei

Huawei Inverter and Battery Review

Jun 22, 2023 · The SUN2000-L1 series ranges from 2kW to 6kW and features ''dual MPPTs'' with a wide operating voltage range of 120V to 600V. Like the first-generation inverter, the new

Set Q-U and P-U through FusionSolar APP

Feb 1, 2022 · Therefore, such information is provided for reference purpose only and constitutes neither an offer nor an acceptance. Huawei may change the information at any time without

2014 High String Voltage to Ground

2014 High String Voltage to Ground Alarm Attribute Possible Cause Suggestion If no PID compensation device is deployed in the system, disable the PID protection function. Note: If

SUN2000-100KTL-H1 Output Characteristics Curve

Oct 10, 2018 · When altitude > 4000 m, DC voltage derating of SUN2000 inverter should be taken into consideration and DC voltage derates in accordance with 19.5V/100m. The rated AC

Connecting DC Input Power Cables

Before connecting the DC input power cables, ensure that the DC voltage is within the safe range (lower than 60 V DC) and that the DC switch on the inverter is OFF. Failing to do so may result

Huawei FusionSolar Commercial & Residential PV

Jul 24, 2019 · *1 The maximum input voltage is the upper limit of the DC voltage. Any higher input DC voltage would probably damage inverter. *2 Any DC input voltage beyond the operating

Recommended Requirements for Inverter Application

The MPPT voltage of PV strings should be within the full-load MPPT voltage range of the inverter. If the MPPT voltage of PV strings is too high or too low, it results in great component loss,

6 FAQs about [Huawei inverter voltage]

What is a second generation Huawei inverter?

The second generation of Huawei inverters hit the market in April 2020, two years after the first. The SUN2000-L1 series covers powers from 2kW to 6K, features two MPPT inputs and an operating voltage range from 100V to 600V. The SUN2000-L1 model is a hybrid inverter ready to connect to an energy storage facility.

Can a Huawei inverter be used under a photovoltaic module?

Optimizers can be used under selected PV modules, and optimizers can be installed under each photovoltaic module. Huawei inverters even have a built-in IV voltage- current curve tester. Huawei inverters are equipped with the PID recovery function, which limits the degradation of photovoltaic modules by the PID phenomenon.

Do Huawei inverters work with energy storage units?

Huawei inverters are adapted to work with energy storage units (L1 and M1 series) – you can choose from an LG or Huawei Luna2000 battery. Inverters can function without optimizers, just like classic string inverters. Optimizers can be used under selected PV modules, and optimizers can be installed under each photovoltaic module.

Is Huawei a hybrid inverter?

Then, only two years later, Huawei released the second generation residential hybrid inverter, a new compact optimiser, a range of 3-phase hybrid, and large commercial inverters with advanced capabilities. Huawei pronounced “Hua-Way’ is a Chinese communications and technology company mainly known for its mobile phones.

Does Huawei have a DC/AC Ratio limit on solar inverters?

ads in low-light conditions during the winter season.Huawei has designed the SUN2000 solar inverters such that they can operate in “clipping” mode for sustained periods of time. Therefore, Huawei will not pose firm limits on the DC/AC ratios on its inverters, provided that the desi n

Does Huawei inverter have a battery charging function?

Unfortunately, there is no battery charging function in the island mode of the 3-phase inverter – we only use the energy available in the warehouse until it runs out. Huawei inverters are aesthetically designed and manufactured devices. They have the so-called natural cooling, i.e. no fan.

Learn More

- Pwm control inverter voltage and current waveform

- Huawei Photovoltaic Power Inverter Y Type

- Huawei communication base station inverter grid-connected market share

- Inverter voltage and current

- Huawei communication base station inverter grid-connected revenue

- Huawei PV Inverter OEM

- Huawei inverter in Mombasa Kenya

- Prague photovoltaic inverter output voltage

- Tl494 inverter output voltage is low

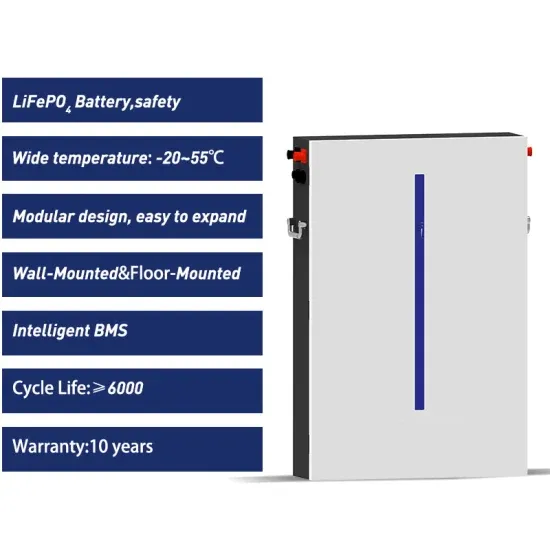

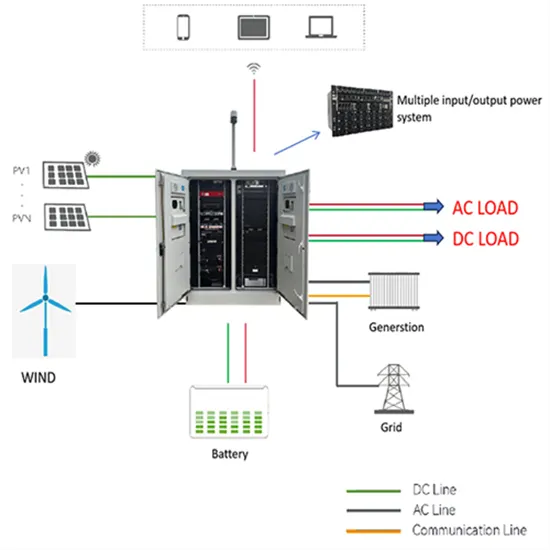

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.