Solving the Optimal PWM Problem for Single-Phase

Mar 18, 2004 · This paper describes a contribution to the theory and practice of optimal PWM waveforms that addresses this question. A PWM waveform consists of a series of positive and

Pulse Width Modulated (PWM) Drives

Jun 14, 2016 · The control improves upon the basic volts/hertz control technique by providing both a magnitude and angle between the voltage and current. Volts/Hertz drives only control the

Voltage Source Inverters Control using PWM/SVPWM

Feb 13, 2014 · Three phase voltage-fed PWM inverters are recently showing growing popularity for multi-megawatt industrial drive applications. The main reasons for this popularity are easy

CSM_Inverter_TG_E_1_1

Mar 27, 2016 · Vector control is used to correct the output waveform according to the voltage and current output from the inverter to an induction motor. The motor speed and output torque are

Unipolar PWM Single Phase Inverter with RL Load

Oct 27, 2024 · Unipolar PWM may have limited control resolution compared to other PWM techniques. The binary nature of the control signal (either fully on or fully off) limits the

Multiple feedback-control-loops for single-phase full

Multiple feedback consists of two control-loops; one for capacitor voltage and other for inductor current-control. Output voltage and load curren-feedforward-control is used. This technique

Voltage Source Inverter Reference Design (Rev. E)

May 11, 2022 · To control the inverter stage for desired operation, voltage and current need to be sensed for processing by the digital controller. The design implements sensing scheme based

Voltage Source Inverters Control using PWM/SVPWM

Feb 13, 2014 · A number of Pulse width modulation (PWM) schemes are used to obtain variable voltage and frequency supply. The most widely used PWM schemes for three-phase voltage

Solving the Optimal PWM Problem for Single-Phase

Mar 18, 2004 · A PWM waveform consists of a series of positive and neg-ative pulses of constant amplitude but with variable switching instances as depicted in Fig. 1 (as in a power electronic

Simulation and Design of A Single Phase Inverter with

Sep 17, 2020 · There are several control techniques for inverters. The most common one is the Pulse Width Modulation (PWM) technique. The main aim of these modulation techniques is to

Inverter PWM Control

Sep 1, 2023 · The motor exchanges its AC power with the DC power from the battery via a PWM voltage source inverter (VSI). Control outputs of voltage signals, in magnitudes, frequencies or

Bipolar PWM Single Phase Inverter with RL Load

Oct 27, 2024 · Introduction A bipolar PWM single-phase inverter is a type of power electronic device used to convert DC (direct current) power into AC (alternating current) power with a

6 FAQs about [Pwm control inverter voltage and current waveform]

What is a pulse width modulation (PWM) inverter?

Pulse Width Modulation (PWM) inverters offer several significant benefits over traditional square wave inverters: Precise Control: They provide exceptional control over output voltage and frequency, which is crucial for sensitive electronic devices and efficient motor control.

How does a PWM converter work?

The output waveform’s shape is controlled by the PWM (Pulse Width Modulation) converter’s output voltage, processed according to the input AC power signal, to generate a specific inverter waveform shape and frequency. Moreover, the circuit topology of the inverter greatly influences the resulting output waveform.

What is a 3 phase PWM inverter?

Three-phase PWM inverters have a similar operating principle to single-phase inverters but use six power switches arranged in three legs. The control unit generates three separate PWM signals, one for each phase. These signals are used to control the switching of the IGBTs to produce three-phase AC power.

What are the applications of PWM inverters?

The advanced PWM technology in Hinen inverters enables intelligent peak-shaving functionality, which can significantly reduce electricity expenses and adapt to price fluctuations. PWM inverters play a crucial role in various applications, particularly in renewable energy systems. Check out the key applications of PWM inverters:

What are the different types of PWM inverters?

Table 2.1 provides an overview of inverter categories. Voltage-type PWM inverters are most commonly used. These inverters are further divided into two categories, depending on the commutation method used: 120° commutation primarily used for small motor applications and 180° commutation used for many motor and power supply applications.

Why is PWM a sinusoidal waveform?

PWM varies the width of pulses required for the switching of transistors in an inverter in order to generate an output waveform composed of many narrow pulses in each cycle. As a result, the average voltage of the modulated output pulses becomes sinusoidal.

Learn More

- Inverter voltage and current

- How does the inverter control the voltage

- Inverter voltage space vector control

- Inverter output high voltage and low current

- Inverter shutdown voltage

- Morocco high voltage energy storage inverter manufacturer

- Inverter charging voltage is low

- Battery voltage and inverter

- 35kv high voltage inverter

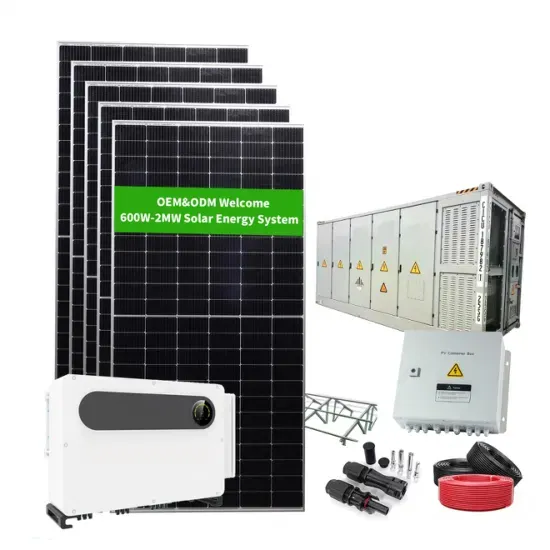

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.